Authors: T. E. Oseng-Rees, A. J. Clayton, N. R. Haigh, D. J. Coathup & J. J. Tomes

Source: Glass Structures & Engineering | https://doi.org/10.1007/s40940-025-00300-8

Abstract

We present the findings of environmental exposure and impact testing on the commercialised output from a spin-out company producing fused recycled glass material, evaluating its suitability for architectural use in both commercial and domestic settings. Recycled glass from various post-consumer sources has been processed and reshaped into a new crystalline material. The raw glass, sourced from consumer discarded bottles and plate-glass from demolition sites, has been crafted by hand and fused in a kiln to form large sheets of fused recycled glass. As part of its circular economy efforts, the fused recycled glass material is free of any additives, resins, or inorganic binders. To determine suitability for architectural use installed externally or in kitchens and bathrooms, the fused recycled glass material was cut into tile shapes and subjected to accredited standard testing methods. Five samples from seven different glass types were evaluated in an accredited setting of dry heat, damp heat, and freeze–thaw cycles. The samples underwent five cycles of exposure to the aforementioned conditions. Close visual inspection of the tiles from all glass material types showed no effects from the extreme conditions and remained in the same state as they were prior to testing. Impact resistance testing of the glass samples produced varied results for each type of glass material and its origin. Two tile sets were found to have the same impact energy resistance as commercially available ceramic and porcelain tiles of similar dimensions. This affirmed the validity of using fused recycled glass material in architectural applications.

1 Introduction

A comprehensive investigation on the development of a fused recycled glass material that is viable for architectural installation was conducted through a PhD research project. The fused recycled glass material is manufactured with a focus on circular economy principles, as such it is free of any additives, resin or inorganic binders and is made from a low-temperature fusion technique which is considerably less energy intensive than glass remelting. Testing was conducted to determine the flexural strength and elastic modulus of this novel material, with results published by Oseng-Rees et al. (2014) and Oseng-Rees and Donne (2015). A spin-out company was established in 2017, to commercialise the outputs of the research.

In this paper we present the results from environmental exposure and impact testing of the production output material from the spin out company, to determine the material’s suitability for architectural use in both commercial and domestic settings.

Glass recycling has become a part of every household in the UK, often with weekly collection by local councils in residential areas. However, for conventional glass recycling, the quality of the waste glass is an important factor as the level of impurities must be considered for reuse of the material (Bristogianni et al. 2020) and (Bristogianni et al. 2018). All glass can be recycled if it is segregated into similar production types of glass. In the UK, container glass comprises 60% of mass output with a recycling rate of 76.5% in 2019 thanks to extended producer responsibility and investment in collection methods. The remaining 23.5% is consequently taken out of the circular economy. Flat glass for architectural and automotive use comprises 30% of mass output which by comparison to container glass is rarely recycled into new flat glass products (Hartwell et al. 2022). This low level of recycling of flat glass results in approximately 200,000 tonnes of waste sent to UK landfills, highlighting the need for improved resource recovery and environmental preservation. In the EU, recycling all building glass waste could prevent 925,000 tonnes of landfilling and save 1.23 million tonnes of primary raw materials annually (UK Green Building Council 2023). Employing an up-cycling approach, whereby glass material can be broken into fragments, or cullet, and fused together in a kiln to form a solid thick-walled structure, can not only reduce landfill waste, but also produce useful products that can be utilized again for a variety of purposes (Bristogianni and Oikonomopoulou 2022). This circular approach has the advantage of a simple material supply mechanism, which also reduces the energy required to obtain the new material and make it into a product (Nilson et al. 2007). This has a real positive impact on reducing carbon dioxide emissions (Hestin et al. 2016) and combating issues relating to landfill space. There is an increased advantage if the waste glass from which the cullet is obtained is sourced from post-consumer products. Fused recycled glass material could be used in architectural structures and settings, particularly as wall tiles, a façade at a reception desk, or as a screen within an office. However, to be considered as a building material in the same manner as ceramic, porcelain, and slate, a new product needs to undergo standardised testing to satisfy both building and safety regulations. This has been investigated to some extent by Bristogianni et al. (2020) of which key mechanical properties of the recycled glass variations, mainly flexural strength, and young's modulus were identified. However, we present here further, standardised testing to help certify such fused recycled glass materials manufactured from waste streams as a valid state of the art architectural product.

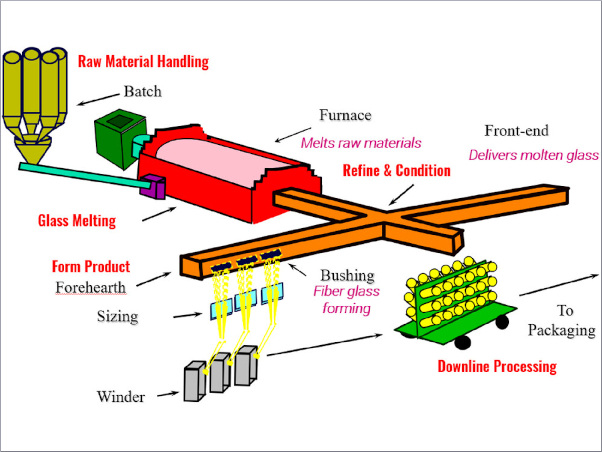

In architectural settings, the use of glass, ceramic, porcelain, and slate materials is widespread. Slate must be mined and cut into desired shapes, which often involves the services of skilled workers or specialist machines and adds to the price of the material (Gerassis et al. 2019), whilst ceramic and porcelain are both made from a clay mixture that is extracted from the ground and processed (Framinian et al. 2014). Both clay and glass become permanently hardened by firing, but the major difference is that clay is a plastically deformable material that is manipulated in the cold state and hardens during firing, turning into a crystalline material known as ceramic, by comparison glass is largely operated on in its hot molten stage and hardens during the cooling stage. Clay is often fired to a biscuit state which is porous and needs a glaze to make it hydrophobic and impervious to water. Clay can alternatively be fired at higher temperature until the production of stoneware or porcelain, the higher temperature turns particles into glass which seals the pores of the material. Commercial glass on the other hand is formed by melting a particular crystalline material which becomes non-crystalline during cooling. The formation of crystals in glass is generally seen as a defect and undesirable since it can result in a cloudy surface, thereby diminishing the glass's chromatic brilliant texture and potentially introducing a weakening effect. However, there is exception to which a crystalline glazed material on ceramic has proved to have remarkable range of properties, of which is excellent resistance to both thermal and physical shock (Bray 2000). Building upon this knowledge, the present study aims to investigate whether a novel fused recycled glass material, subjected to controlled crystallisation, possesses similar properties to those observed in crystalline glazes. Therefore, the focus of this paper is to comprehensively examine the potential of the fused recycled glass material for its suitability for architectural use in both commercial and domestic settings.

The input raw material is sourced from post-consumer waste glass that has been collected, washed, and crushed into a raw cullet. It is then placed on to refractory moulds also referred to as kiln shelves, which are coated with a mixture of kaolin and alumina hydrate which acts as a release agent. The heating elements are located above the glass, while the underside of the fused glass is the face that comes into contact with the mould material, ensuring a flat surface. The glass is heated to a temperature below 900 °C to form a flat sheet for cutting. Following fusion, the glass material is cut into tile shapes using a wet diamond tile saw, and no additional polishing or edge grinding is performed on the tiles after this final process.

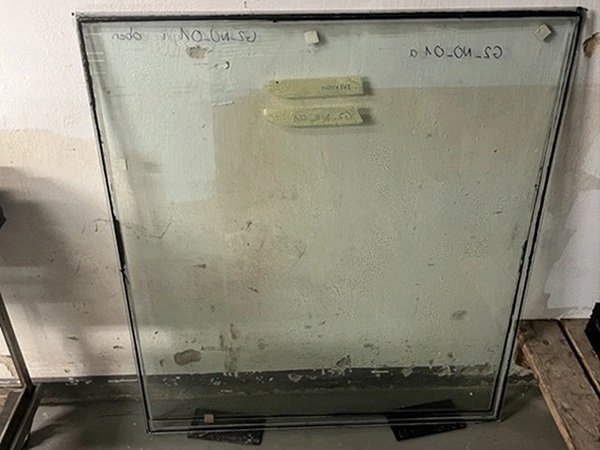

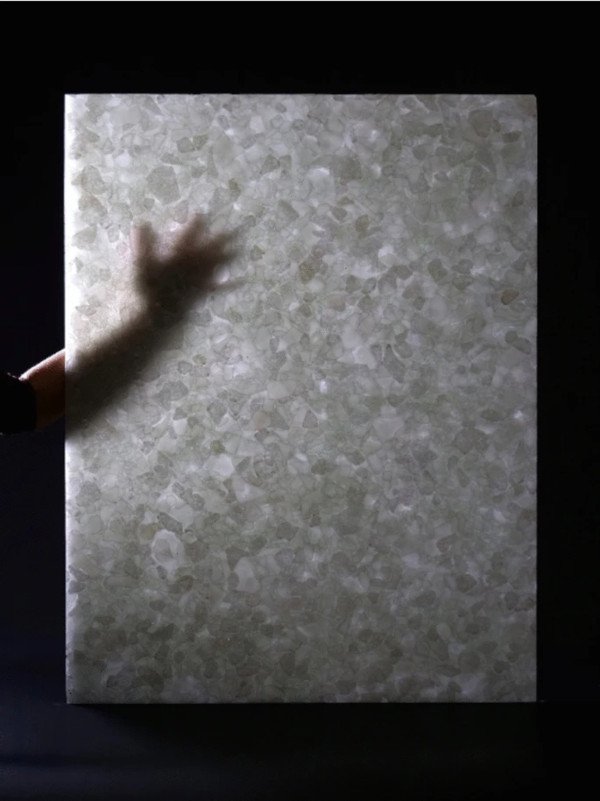

The manufacturing process for this fused recycled glass material is distinctive and involves a tailored thermal process to boost the development of a crystalline structure. Consequently, this product does not look like glass, rather it resembles stone or marble with a semi-transparent appearance of which individual glass fragments are still visible within the material after manufacturing, as presented in Fig. 1. The finished material holds the arrangement of the cullet pieces after the fusing process, and the crystalline structure is formed on the surface boundary between each cullet piece. Compared to float glass the material does not have a transparent, uniform structure, but instead, that of a semi-opaque crystalline material. To make a fully homogenous structure through melting would require temperatures higher than 1150 °C, which would increase the carbon footprint and lower the environmental sustainability of the material. A full melt process would also change the desired effect aesthetically.

The focus of this paper is to investigate the architectural suitability, both commercially and domestically, of what is a sustainable material, produced by a UK-based spin-out company which specializes in manufacturing fused glass panels entirely from waste glass. While a German company, Magna Glaskeramik, has a proven track record in upcycling glass waste for architectural applications, their physical location makes it challenging to utilise their expertise in reprocessing UK sourced waste. In terms of utilising alternative types of waste materials within the construction industry, two noteworthy UK-based entities are Smile Plastic, known for upcycling waste plastics, and Ministry of Furniture, excelling in the remanufacturing of office furniture. It is worth noting that, as of now, the only UK-based business dedicated to upcycling waste glass is Oseng-Rees Reflection Ltd.

2 Methodology

For new materials to be considered for construction purposes they require validation testing under standard conditions, a wide range of British Standard (BS), American Society for Testing and Materials (ASTM) and International Organization for Standardization (ISO) tests are available for the technical evaluation of glass and ceramic materials used in architectural applications. Here we selected tests to determine the suitability of the fused recycled glass tile samples for outdoor use and exposed to European freeze thaw weathering, as well as for vertical internal domestic installation in kitchens and bathrooms where they may be subject to damp heat cycling.

To achieve our aims, different sets of fused glass tiles manufactured from different domestic and demolition glass waste were subjected to a series of standard environmental test conditions and evaluated for any signs of damage after each test condition. These tests followed standards (detailed in Sect. 2.3) for resistance to freeze–thaw and frost conditions, dry heat, damp heat environments, and resistance to impact, which are set out for ceramic and glass tiles, as well as natural stone and electrical and consumer goods.

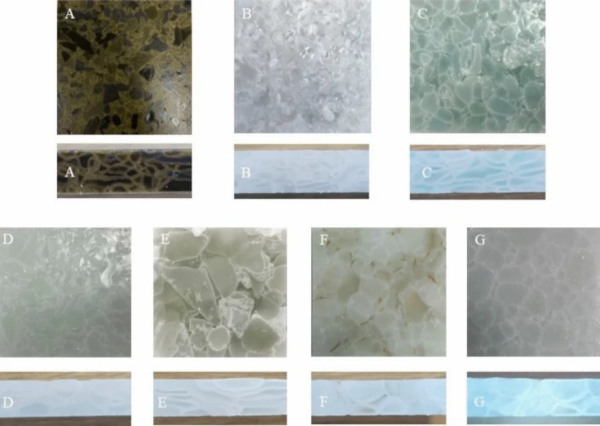

2.1 Categorising glass tile sample sets

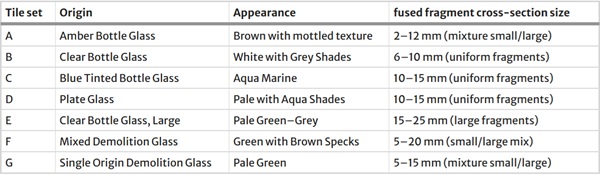

Seven types of waste glass were used to produce the fused glass tiles that were subjected to environmental testing. Each tile type consisted of six 10 × 10 cm samples, with five samples subjected to environmental testing and one sample kept as a control. The sample sets were labelled A–G, all being composed of recycled soda lime glass material used in different consumer products. Sample A, B, C, and E derived from bottle glass and sample D, F and G derived from construction waste some of which was seen to have surface coatings and when processed can leave observable brown colouration at the fragment boundaries as seen in Fig. 2. Two types of commercial CE compliant ceramic tiles of similar size and visual features to the glass tiles under test were purchased for comparison and included for reference in the environmental regimes for comparison. The origin of the fused recycled glass tiles is described in Table 1, with an example of each sample type shown in Fig. 2.

Table 1 Origin of the waste glass recycled and fused into different tile sets with a description of the (post processed) fused fragment size range obtained from 10 randomly selected pieces per tile - Full size table

The broken glass has been categorized according to size criteria. Fragments below 2 mm were excluded from this experiment, while “small” fragments range from 2 to 12 mm, and “large” fragments are 12 mm and above. As indicated in Table 1, the glass fragments composing the tile body appear either as a mixture of both small and large or as uniformly sized fragments within the specified size ranges. During manufacture even though the broken glass fragments were initially placed in an unstructured manner inside the mould, during processing they flattened and naturally orientated with fragment longer surfaces aligning in parallel to the mould base and each other. Proprietary processing parameters rather than the source material curvature have predominant influence over tile flatness.

In Fig. 2, each tile set is shown from the top presentation surface and from the side as a cross section through the thickness of the material. Demolition glass sets F and G were composed of bulky fragments, which is consistent with the fragment characteristics of a broken glass pane made from 10 mm thick toughened glass. When toughened glass fractures, it forms uniformly sized fragments, and from the cross-section view, a small density of fused glass boundaries was observed, indicating that the tile thickness is defined by the fusion of two glass fragments. The other glass tiles (A to E) originating from bottle glass and plate glass were composed of five or more smaller fragments layered on top of each other to define the tile thickness. Comparison of recycled glass tile sets B and E, which were both made from the same source clear bottle glass but had a different fragment size structure on the fused glass, of which B was made from fragment sizes between 6 and 10 mm and E was made from larger fragment size glass (15–25 mm). As can be seen In Fig. 2, the surface of the tiles clearly shows the distinction between the sizes of the broken glass fragments used in their composition and on the cross section for tile set E the boundaries between the glass fragment were longer, whereas tile set B had shorter block-shaped fragments.

Each tile sample was visually inspected for any defects using naked eye observation prior to environmental testing. This was also carried out for the commercial ceramic tiles used as a control sample in the testing regimes. Each tile set was first exposed to the dry heat testing regime for 24 h and subsequently control weighed as a baseline measurement. The tiles were then subjected to five cycles of damp heat testing, followed by five cycles of the freeze–thaw tests.

2.2 Tile assessment post-test regime

The features of the tiles were monitored for any visual change from the initial inspection with each test regime. A photograph was taken of each tile after each test so that side-by-side comparison could be made, as well as a close visual inspection and a record taken of any noticeable characteristics. The following inspection was made:

- Surface glass fragments flaking off

- Delamination between glass fragments / grains

- Crack propagation within fragments / grains

- Crack propagation crossing fragment / grain boundaries

- Hairline crack formation or propagation

- Pin hole enlargement

- Change in pin hole shape

- General discolouration of the tiles or fading of colour

- Discolouration around pin hole edges

Certain features were noted on tile samples prior to being subjected to testing. These characteristics were monitored throughout the testing process and were considered the most likely areas to show any change. Features such as pin holes were monitored, for changes in shape, size, or colour. A "pin hole" in this context refers to a small, round defect in the material surface which can appear during the manufacturing process due to influencing factors such as air bubbles, impurities, or uneven heating. These pin holes can compromise the integrity or aesthetics of the material. Any cracks forming along boundaries of the fused fragments were also investigated. The mass of each tile was recorded prior to any testing and after each test regime and cycle to monitor for any changes. Tile mass was measured using RS Pro KS-104 2028725 laboratory scales with a reading to two decimal places, which was supplied by RS Components Ltd.

2.3 Standardised testing of fused recycled glass tiles

The test standards used are listed below:

- ASTM C1026—13 (2018) Standard Test Methods for Measuring the resistance of Ceramic and Glass Tile to Freeze–Thaw Cycling—Old and Revised tests.

- A look at freeze–thaw resistance: A major North American testing advancement (Astrachan and Marino 2012).

- BS EN 12371:2010: Natural stone test methods. Determination of frost resistance (British Standards Institution 2010).

- BS EN 60068–2-1:2007: Environmental testing. Test A: Cold. Test B: Dry heat (British Standards Institution 2007).

- BS EN 60068–2-30:2005: Environmental testing. Test Db: Damp heat, cyclic (British Standards Institution 2005).

- BS EN ISO 10545–5:1998: Ceramic tiles—Determination of impact resistance by measurement of coefficient of restitution. (British Standards Institution 1998)

- ASTM D7136/D7136M-15: Standard Test Method for Measurement of the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event (ASTM 2015).

- BS ISO 29584:2015: Glass in Building. Pendulum Impact Testing and Classification of Safety Glass. (British Standards Institution 2015)

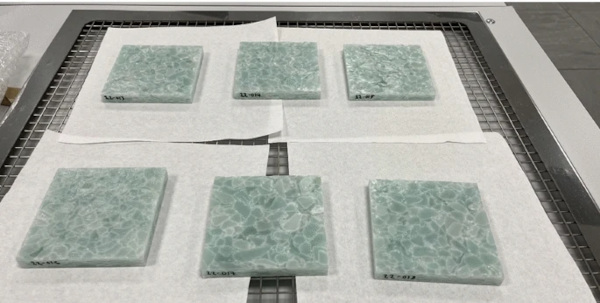

Two types of ceramic tiles of similar aesthetic characteristics were purchased from a commercial tile outlet and included in the testing as reference samples. A sample of each tile (ceramic and recycled glass) was left out of the testing regimes as a control for reference. The environmental tests were carried out using a chamber manufactured by James Technical Services (JTS) Ltd. (Fig. 3) following the British Standard BS EN IEC 6008-2-1:2007 for freeze–thaw and dry heat and BS EN IEC 60068-2-30:2005 for damp heat. The environment monitoring was recorded using a K-type thermocouple to monitor temperature which was recorded using PicoLog software.

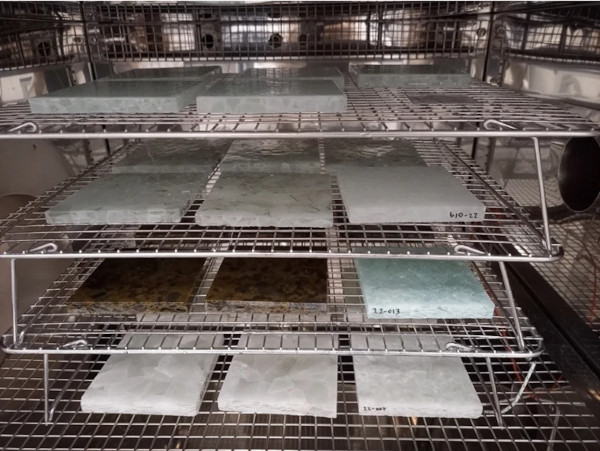

Samples were placed on stainless steel shelving (Fig. 4) to allow five samples of each tile set to be positioned within the chamber. The tiles were placed randomly on each stainless-steel shelf, leaving gaps between each tile to ensure uninterrupted air flow within the chamber, which was essential in achieving consistent environmental conditions between samples. Each tile was positioned with the underside (defined as the face in contact with the mould during manufacture) resting on the shelf, while the top side was positioned facing upwards. The shelving consisted of wire racking which allowed the backs of the tiles to also be fully exposed to the conditions within the environmental chamber.

2.4 Dry heat environmental condition cycling

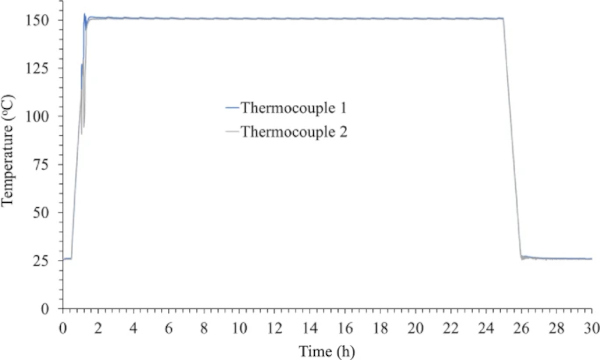

Figure 5 shows the temperature profile recorded using the PicoLog software associated with the independent thermocouple readings taken from within the environmental chamber. The two independent thermocouple readings correlated with each other and with the internal reading indicated on the environmental chamber itself, which was set to 150 °C over 24 h following BS EN IEC 6008-2-1:2007. The glass tiles were visually inspected post dry heat conditioning with no onset of defects or any notable changes prior to testing being observed.

2.5 Damp heat environmental condition cycling

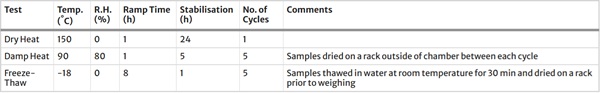

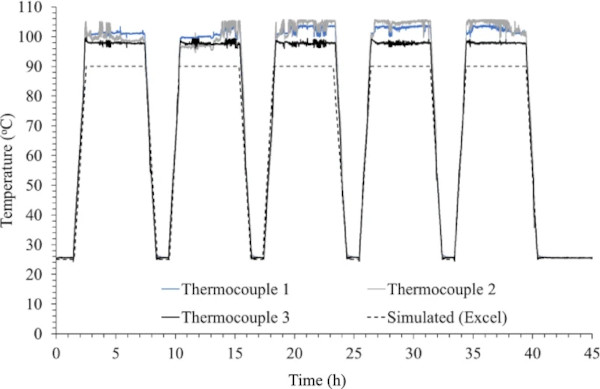

The damp-heat environmental testing was applied to the tile samples following the initial dry-heat cyclic testing. The recorded temperature profile is presented in Fig. 6 where the indicative readings from the thermocouple probes are displayed as exceeding the chamber setpoints. The deviation in the temperature readings was attributed to the performance of the thermocouples themselves, rather than the chamber, which was operating within its annual calibration cycle and service period. Details are summarised in Table 2.

Table 2 Summary of the different testing conditions the seven tile samples sets were subjected to - Full size table

2.6 Freeze–thaw environmental condition cycling

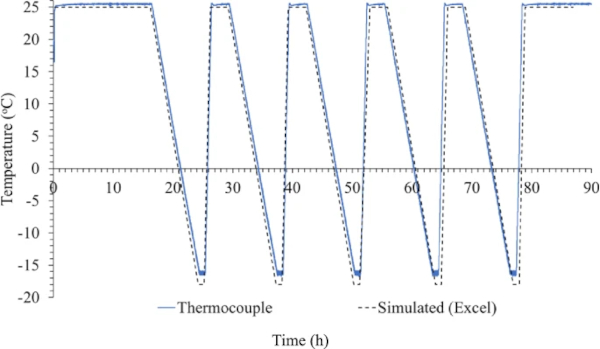

For the freeze–thaw testing, a total of five cycles were conducted, with each cycle comprising the sample first frozen to a temperature of -18℃ in the test chamber and then immediately transferred directly into a water bath at room temperature in the laboratory in accordance with ASTM C1026—13 (23018). The tiles were allowed to thaw for 30 min in the water bath then taken out and placed on a rack under an air flow to remove the presence of surface water before being weighed. The five freeze–thaw cycles were applied to five glass tile samples from each glass tile set and to one of the ceramic tile samples from each of the two ceramic tile sets. A single sample from each set was retained as a control. Cycle details are summarised in Table 2

As seen in Fig. 7, the temperature reading of the thermocouple in the chamber (blue solid line) is noted to be in slight disagreement with the temperature setpoint of the environmental chamber (black dashed line). This is quite common for logging of temperature using thermocouples, and the thermocouple profile is for indication only. The test chamber features internal temperature logging probes which were within their stated calibration period.

The testing regimes are summarised below:

2.7 Impact testing

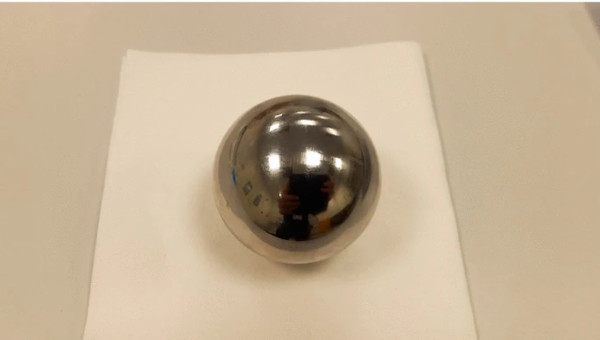

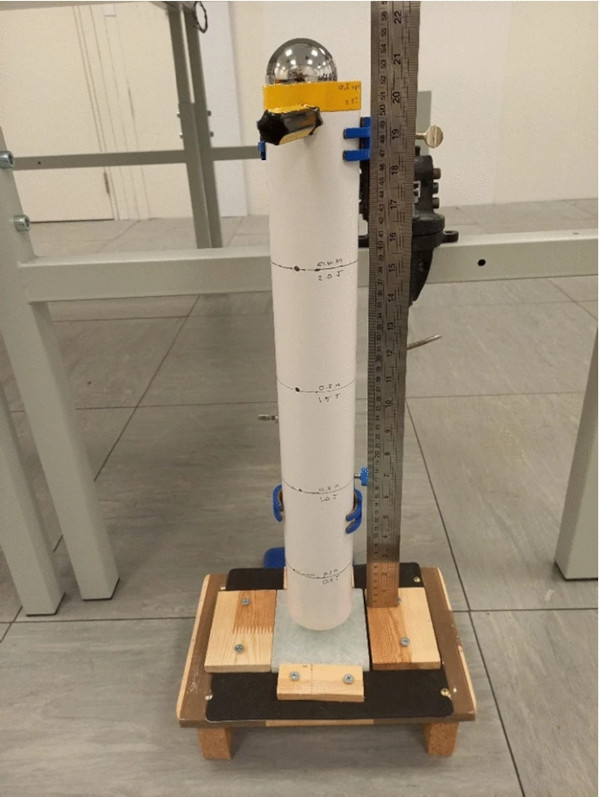

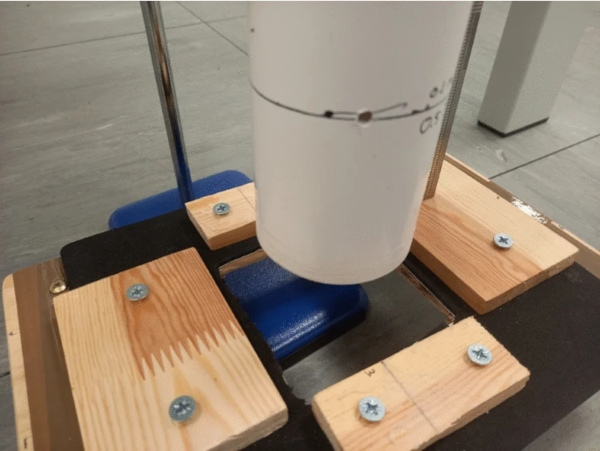

Impact testing on the fused recycled glass tiles was carried out after the environmental test conditions had been completed. The set-up for testing was devised to produce impact energy up to 1.0 J (J) using a similar approach reported by (Halley et al. 2017), which follows a combination of two British Standards. The first, British standard BS ISO 10545-5:1998 used a steel ball of known weight 0.51 kg (Fig. 8) and a vertical drop test, whereby the coefficient of restitution is determined from the height of rebound of the steel ball. Determination of the coefficient of restitution was not carried out under the tests on recycled glass tiles, with only the result of impact being recorded as tile breakage or tile staying intact. The second British Standard, BS ISO 29584:2015 specifies the edges of the glass tiles to be supported by neoprene, silicone, or rubber. The impact testing equipment was set-up in-house comprising a clamped downpipe half a metre in length (Fig. 9) used to guide the steel ball on to a tile placed onto a platform supported by neoprene at the edges and made to fit the glass material samples of 10 × 10 cm (Fig. 10). The height of the steel ball was set using metal pin through drilled holes keeping the steel ball at rest prior to being released. The height from the pin to the tile surface was checked before the steel ball was dropped vertically on to the tile below to ensure the correct impact energy was applied. Each sample was positioned with the tile underside resting on the neoprene, while the tile top side was positioned facing upwards, which the steel ball impacted on.

The equations to calculate the required drop heights for delivering impact energy of 0.2–1.0 J were taken from Halley et al. 2017, and are based on the law of conversion energy where potential energy (PE) before an event takes place is equal to kinetic energy (KE) after the event has occurred. The drop height (h) was calculated using the equations below.

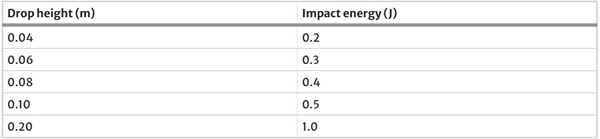

where, m is the mass (kg) of the steel ball (measured at 0.51 kg), g is the acceleration due to gravity (m s⁻²), which is equal to 9.81 m s⁻², and h is the drop height (m) that was varied, giving the potential energy (PE) in kg m⁻² s⁻². This converts directly into energy units in joules. Table 3 presents each drop height and the corresponding impact energy used for the impact testing.

Table 3 Drop height and corresponding impact energy for a 0.51 kg steel ball 50 mm in diameter - Full size table

3 Results and discussion

3.1 Environmental tests

The environmental chamber employed its own temperature control and the continuous data recorded for each testing regime was captured out using two independent K-type thermocouples connected to PicoLog recording software. The thermocouple readings matched closely to the environmental chamber set point temperature for the dry heat and freeze–thaw environmental regimes. The temperature reading for the damp heat environmental regime was slightly higher than the set point temperature for the environmental chamber control. This was expected and can be attributed to the 80% relative humidity having an influence on the thermocouple reading. The thermocouple reading matched the set point temperature once the temperature dropped below 90℃.

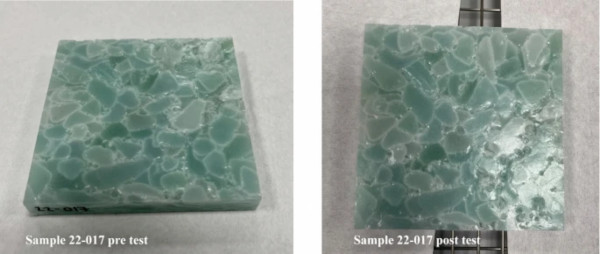

Notable characteristics and features, such as pin holes, that may act as a starting point for defects or fracture were identified on the tiles prior to any exposure to testing. After each environmental test regime every glass tile was inspected closely, paying particular attention to the individual features recorded for each tile. Figure 11 presents samples in tile set C post-test and ready for inspection. Figure 12 shows tile sample 22-017 from set C both pre-test (left) and post-test (right). None of the recorded features showed any visual change after any of the environmental testing conditions. No discernible differences before and after testing was observed for any of the tile sample sets.

No significant visual deteriorations were observed in the glass tiles. The highest mass variation recorded between each testing regime was ± 0.4 g, representing a ± 0.2% difference from the average weight of 200 g. This was the case for all testing regimes and occurred for the control tile samples in each set that did not undergo any environmental testing conditions, other than be kept under an ambient laboratory environment. These small deviations were likely due to combinations of the random uncertainty associated with the measurement of the tile mass and/or the change in the ambient environment of the laboratory.

The only notable change in mass occurred for the commercial ceramic tiles after being exposed to the thaw process when submerged in water after having been exposed to -18℃ in the environmental chamber. The porous nature of the ceramic tile at the back non-glazed surface resulted in the tiles gaining a mass of up to 19.6 g, representing an increase of 13.3%. However, over time, this mass decreased and measurement of the same ceramic tile after a week revealed the mass had returned to the original value recorded prior to any testing.

3.2 Tile resistance to impact

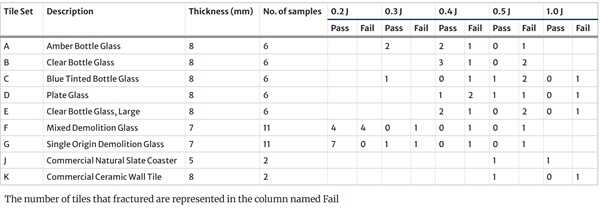

The tests carried out in our study employed a vertical drop test with each glass tile supported in the horizontal position. Different impact energies were used by varying the drop height, calculated using Eq. 2. These drop height tests were also carried out on commercially supplied tiles made from natural slate, ceramic and porcelain for comparison. The quantity of tiles and impact energy (J) that each set of samples withstood without fracturing is presented in Table 4, alongside the number of tiles that did break. Only the recycled glass tiles were tested through the different environmental conditions prior to the impact drop test, with the ceramic, porcelain and slate tiles being tested as supplied.

Table 4 Impact energy resistance for different glass tiles with comparison to commercially supplied slate, ceramic and porcelain tiles - Full size table

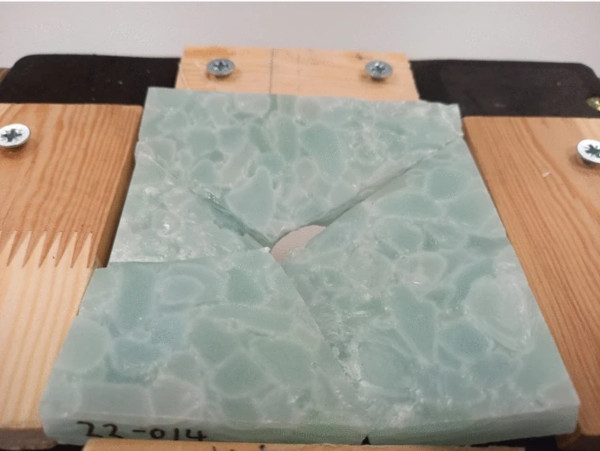

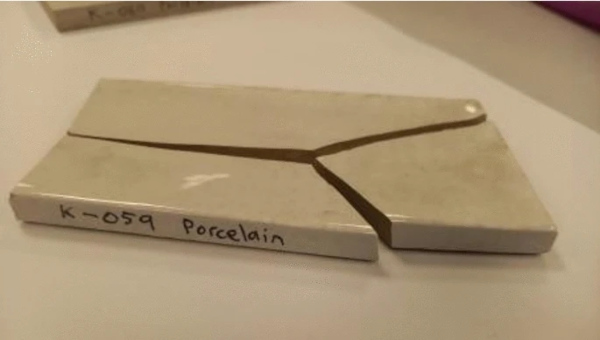

Table 4 indicates impact resistance. In the columns from left to right shows the Sample Set followed by description of the tiles, tile thickness and the number of tiles available for testing. The next five columns show the increasing Joule impact (0.2–1.0 J) applied to the tiles. Tile A-E had six available tiles to be tested as indicated in the column (No of Samples), Tile F and G had eleven samples available for impact testing. This was the first time demolition glass (Tiles F and G) was evaluated as a source material, hence additional samples were made available for impact testing. Additionally, two samples for each of the commercial tiles were made available to test. The number in the column indicates the quantity of tiles that was tested and either passed (not fractured) or failed (fractured) upon impact. The test results varied depending on the glass source. The glass tiles found to have the highest impact resistance (0.5 J) were from sets C and D, which were made from blue tinted bottle glass and plate glass, respectively. However, not all the tiles from these sample sets (C and D) remained intact at this impact energy (0.5 J), as the number in the fail column records tiles that fractured. The commercially available ceramic and porcelain tiles, which are used as wall and floor tiles, also withstood an impact energy of 0.5 J, breaking at 1.0 J. More samples of these tiles would be required for further analysis.

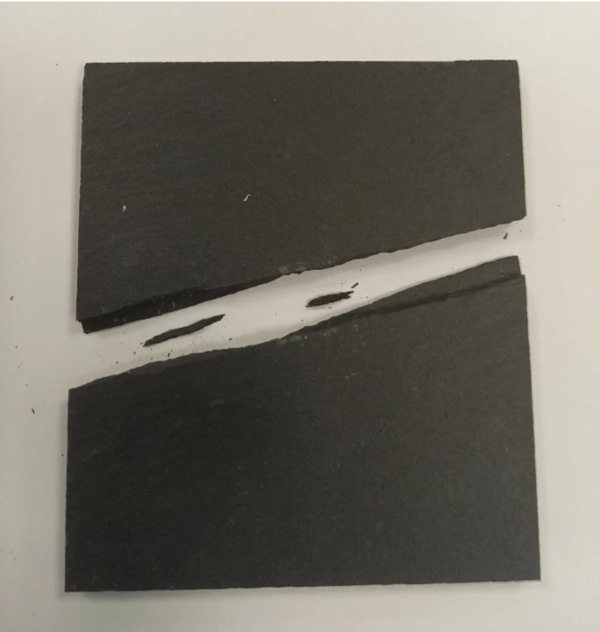

The most resistant tile to impact was the natural slate tile (1.0 J) that was slightly thinner than all other tiles at five mm thick. The superior impact resistance of the natural slate tiles could be expected, due to its formation over millions of years as sediment, minerals and rock are ground under pressure from tectonic plate movement to form a fine- grained metamorphic rock (Gerassis et al. 2019). It was also observed that when the slate tiles did break under the impact test the fragments had sharp edges, more so that of the glass, ceramic and porcelain tiles, in addition to sharp needle-like flakes coming off from the broken edges (Fig. 13).

Both types of demolition glass (F and G) fractured upon impact with the lowest energy of all the recycled glass tiles. These tiles were a little thinner at seven mm than the other recycled glass tiles that were approximately eight mm thick. The single origin demolition glass had all seven samples remaining intact after an impact energy of 0.2 J, whereas the mixed demolition glass had four out of eight tiles breaking upon this impact energy. The tiles made from demolition glass showcased larger and more substantial cullet pieces compared to those in bottle and plate glass. Consequently, these tiles exhibited a lower density of fused glass boundaries, as only two glass fragments defined the tile thickness. The absence of layering in the tiles might have influenced the impact results, warranting further investigation in future research.

Glass tile sets B and E were both made from clear bottle glass but had a different fragment structure in the fused glass (Fig. 2). Both tile sets withstood the same impact energy level of 0.4 J, and fractured at 0.5 J. For tile sets A–E, no clear relationship could be attributed to the fragment size or number of layers and the level of impact energy the tiles could resist and this is worthy of further detailed investigation.

The impact test results showed that the glass tiles produced from recycled material can have the same impact resistance as the ceramic and porcelain tiles. The way in which the tiles fracture is similar, with clear breaks propagating as a homogeneous material, in a straight direction away from the impact site (Figs. 14 and 15). No splinter fragments were observed in any of the breakages. The glass at the break edge was no sharper than the ceramic or porcelain break edges. This indicates that tiles made from recycled glass material performs as well as commercially available ceramic and porcelain tiles used in architectural applications. The advantage the fused recycled glass tiles have over the ceramic and porcelain tiles is the use of a waste glass source material and the lower carbon footprint in manufacturing. The glass tiles used in this study were made from a mixed grade of post-consumer glass, which may produce inconsistencies between each collection of the raw material. The combination of components from the source glass and the kiln fusion could influence the impact resistance, of which test results may vary from test to test. This could be explored further beyond this investigation.

4 Conclusions

Fused glass tiles made from recycled soda lime glass formed from a cullet of post-consumer products were tested in different environmental conditions following British Standards set out for ceramic and glass tiles. Similar accredited tests are also outlined for natural stone and electrical consumer goods. All five samples from each fused glass tile set showed no change in appearance after dry heat, damp heat, and freeze–thaw conditions, the latter two tests having five cycles of each environment. Pin hole areas on tiles formed during the fusion process showed no discolouration or change in shape following the extreme environmental conditions. All pin holes and boundaries of the fused glass fragments remained the same after visual inspection before and after testing.

Impact testing was carried out after the environmental cycling conditions on all the fused glass tiles. Impact energy resistance varied between 0.2 and 0.5 J, with the most notable difference being the lower impact energy withstood by the demolition glass. However, it has been established previously that thicker glass tiles are more likely to be stronger, and the tiles which failed at 0.2 J were slightly thinner at 7 mm, than the other glass tiles which were 8 mm thick. Another observation was that the fragments in the cullet of the demolition glass were bulkier than for the bottle and plate glass, with only two glass fragments defining the tile thickness creating smaller density of fused glass boundaries between the fused glass fragments. All samples from the single origin recycled demolition glass remained intact after 0.2 J impact energy compared to the mixed origin demolition glass tiles, for which only 50% remained intact. This implies that the size of glass fragments and possible origin of the recycled glass material does influence the nature of the fused glass tiles.

By way of comparison the recycled glass tiles used by Halley et al. (2017), were also 10 × 10 cm, with a thickness of 17 mm and 25 mm (compared to the 7–8 mm thicknesses used in this study). The 25 mm thick tiles were tested in set of five, with five samples withstanding impact energies of 5 J, and two out of five samples remaining undamaged after an impact energy of 10 J. The 17 mm thick samples were observed to break at 5 J. This showed that as in our study, the thickness of the recycled glass material was an important factor in determining whether a tile remained intact or fractured.

In this study the fused glass produced from recycled post-consumer bottle and plate glass showed greater resistance to impact energy, with no clear relationship between each glass source. It was also observed that different tile samples from the same tile set varied in resistance to impact energy. Due to the random nature of how the recycled glass fragments fuse together in each tile, there may be subtle differences in each tile structure and its resistance to impact. However, the fused glass tiles produced from recycled material showed similar impact energy resistance to commercial ceramic and porcelain tiles utilised in walls and flooring. This demonstrates the feasibility for tiling made from fused glass, recycled from post-consumer products, as a viable approach for sustainable closed-loop manufacture in architectural applications.

Lastly, it must be noted that testing materials made from randomly collected waste glass presents certain limitations. The variability in the composition and quality of the glass can influence the properties and performance of the final product. As waste glass is collected from various sources, it may contain impurities, different chemical compositions, and varying levels of contamination. This inconsistency can make it challenging to achieve consistent and predictable performance during testing the results of which may only be indicative of the final material properties.

Further work could be conducted to fully determine the influence of cullet size, and overall thickness on the impact resistance of production representative tiles. In addition, to gain a deeper understanding of crystal formation during the glass fusing process and its implications on structural integrity, a future recommendation would be to conduct analysis using X-ray diffraction (XRD) and Raman spectroscopy. This could involve exploring the influence of factors such as temperature, cooling rates, composition, and impurities on the extent and type of crystal formation in fused glass. By comprehensively studying and characterising these crystallization processes, it could be possible to predict and anticipate potential breakage patterns, thereby optimising future design and production strategies for enhanced durability and performance.

However, the results presented here affirm the validity of using fused recycled glass material in architectural applications. The findings contribute to the growing body of knowledge on sustainable building materials and support the potential for circular economy practices in the construction industry.