This paper was first presented at GPD 2019 by Elisabeth Klimm, Karl-Anders Weiß and Christiane Siess from Fraunhofer-Institut für Solare Energiesysteme (ISE).

For reproducible qualification of glass types and coatings in-house developed soiling test devices are applied to soil samples homogenously with any kind of natural or standardized dust. The results have been analysed with an in-house built transportable soiling sensor measuring the loss of transmittance.

Artificial Dry Soiling

A dry soiling method with the soiling chamber, explained in previous publications [Klimm 2015] has been applied so distribute standardized (artificial) dust as well as natural dust types homogeneously to glass coatings.

Artificial Soiling with Moisturizing

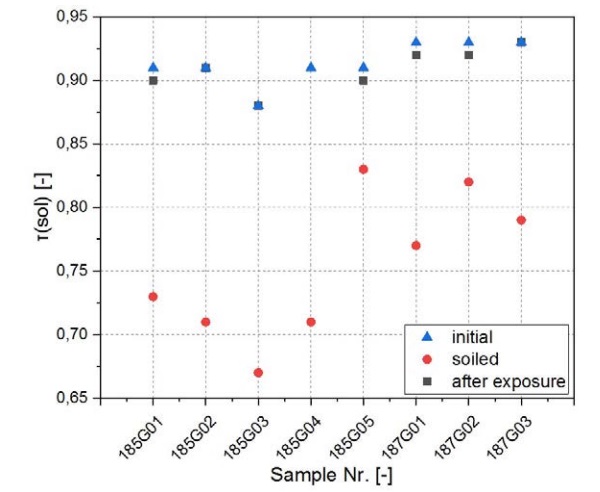

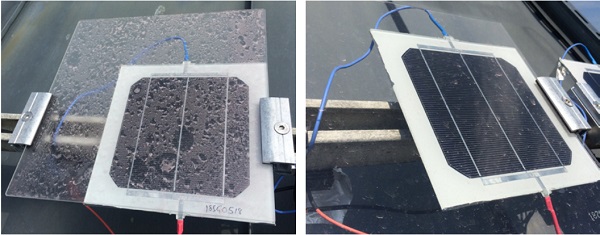

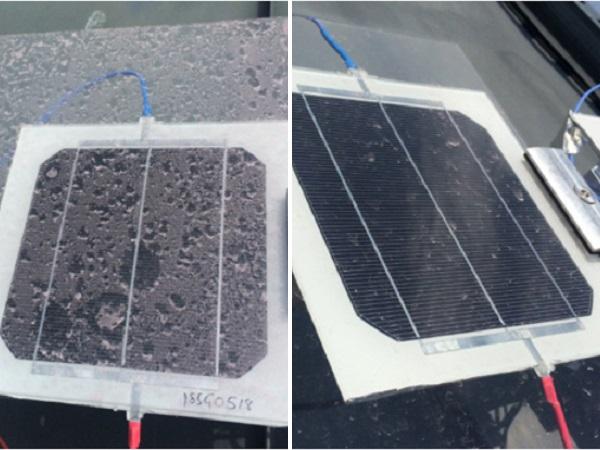

The second approach uses the dry soiling with the artificial test dust SAE 726j with previous surfaces moisturizing for better dust adherence. Moistening was ensured by an ultrasonic nebulizer leaving the samples with a humidity layer of 1.5 µm to 40 µm, depending on the wetting behaviour of the surfaces. Immediately after wetting, a homogenous dust layer of 5 g/m² was applied to the samples (up to 75 x 75 cm²). Solar transmittance is measured with FT-IR spectrometer, Fig. 1. Afterwards soiled samples are mounted and monitored outdoors.

Soiling Sensor Station outdoors

The above mentioned soiled samples with functional coatings and reference samples have been exposed to outdoors to investigate the “self-cleaning” properties. The samples were mounted at the roof in Freiburg, Germany until at least one rain event with > 5 mm or precipitation. Using a PV mini-module provides a very suitable approach to quantify the soiling effect. The ratio of the output electrical energy and the incident solar energy VE allows the comparison of daily values.

Results and Conclusion

For all samples, the dust layer caused up to 57 % performance loss. Rain was able, in most cases, to fully restore the initial performance. The measured transmittance loss, due to soiling, show a correlation to the wetting properties of the surfaces. The unaged sample coatings with hydrophobic surface seem to work best. The samples with low contact angles of ~15° also perform well.

The non-coated glass, as expected, showed still a lower transmission after exposure. The evaluation of the energy ration VE shows that due to the soiling the value drops from ~ 10% to values between 7 and 8%. Thus light rain even deteriorate the problem, accumulating dirt. The presented approach describes a meaningful, fast and easy to apply method to determine information about the soiling behaviour of glass surfaces which are exposed to soiling loads with different dust types.