Date: 5 October 2017

By Tim Kempster, managing director

The catastrophe that has visited the Caribbean and parts of the eastern seaboard of the USA has been appalling to watch.

There have been 13 named tropical storms this year, and the hurricane season doesn’t end until November. Of those, eight have been hurricanes and four of them were major hurricanes.

About 12 tropical storms form in the Atlantic each year. So, this year, it’s been about average – except for the scale of damage which, in places, seems apocalyptic.

Hurricane Irma, for example, sustained winds of 185 mph for longer than any other hurricane or typhoon ever recorded. Maria devastated Puerto Rico.

But while it’s the scale of human suffering that’s the most tragic consequence, the financial cost is also appalling.

Estimates for the financial impact of Hurricane Harvey range from $65 billion to $100 billion – and may yet become the most expensive disaster in the history of the USA.

But we’ve been here before. In 2012, Sandy roared across the eastern seaboard of the United States, causing an estimated loss of some $75 billion.

Mega catastrophe

Or Katrina in 2005, which devastated southern areas of the US. In that cataclysmic event, 1,800 people died, and 80% of New Orleans was inundated with water. Lessons learned back then have undoubtedly saved lives this year.

The insurance industry has a term for these events: mega catastrophe, and their incidence is increasing. In terms of severe weather events, global warming is in all probability to blame, with the likelihood is for more of the same – or worse.

It’s an issue that continues to focus the minds of many people involved in the built environment – from product and system suppliers, like ourselves, to architects, designers and builders and upwards to regulatory bodies and national governments. If our weather is going mad, then we have to build smarter and better.

For the glass and glazing industry, the first real wake-up call came in 1992, when Hurricane Andrew, the second most powerful Category 5 hurricane to make US landfall during the 20th century, bulldozed its way across Florida, killing dozens and causing over $30 billion in damage.

Until Katrina made an appearance, Andrew was the costliest Atlantic hurricane in US history, and led initially to significant changes in the South Florida Building Codes, with new regulations for debris impact, including windows – because when glass breaks or the window frame fails, the enormous change in air pressure inside a building can then cause structural collapse.

Composite glass

After Andrew, and partly also driven by the insurance industry, a new hurricane missile testing regime changed construction practices and building regulations across the United States. It remains to be seen if this year’s hurricanes will have the same impact on today’s building industry.

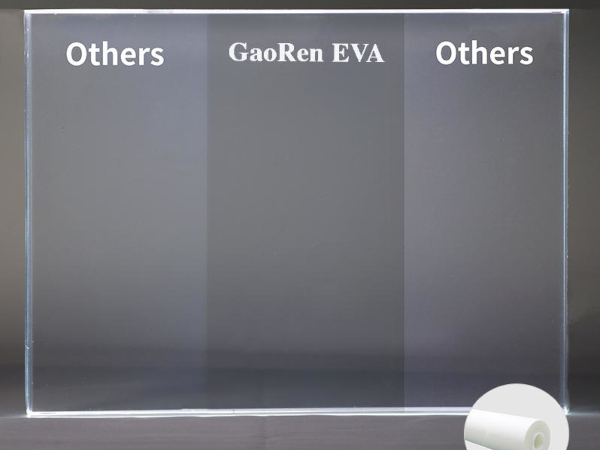

Because of Andrew, new composite glass types came onto the market, specifically designed to withstand the huge pressures generated in storm force or hurricane conditions and, if struck by flying debris, to retain the window or curtain walling element within its framing system.

Of course, it’s not just extreme weather events that can cause glazing systems to fail and turn glass fragments into lethal projectiles. Most damage in some 75% of all urban bomb explosions is caused by glass.

The issue of glass as a terrorist weapon was pushed to the top of the security agenda by the attack on the Alfred P Murray Federal Building in Oklahoma City in 1995. In that attack, 167 people died and 750 were injured, many by flying glass.

A year later and a terrorist attack at a US Air Force base in Saudi Arabia resulted in over 330 injuries, the great majority caused by broken glass. Two years later and it was the same story in Africa when terrorists targeted US embassies in Kenya and Tanzania. Of the 5,000 injured, many were victims of flying glass fragments.

In the intervening years, the glass and glazing industry has invested significantly to understand the dynamics of high wind loading and blast pressures – developing glass and framing systems to keep the glazed element intact and in its frame. Understanding those dynamics has pushed the boundaries of what is possible now with glass.

At Wrightstyle, our business starts with developing and testing entire systems for compatibility – whether they are internal partitions or large expanses of roof glazing or curtain walling. We were therefore able to take a holistic approach, designing and rigorously testing our ideas, marrying glass types to framing systems and finding innovative ways to reduce profile widths.

Glass and framing compatibility

The simple fact is that, on paper, a system may appear to offer high wind loading or blast protection. However, put that glass type into an incompatible framing system and, while the laminate glass may remain in one piece, it may also be blown in its entirety from its frame – causing the very primary and secondary injuries that it was designed to protect against.

The objective of our research journey has been to incorporate new technologies in the development of safer glazing systems (and in larger spans) to mitigate against the threats of fire, extreme weather or terrorist attack. For example, we now have a glazing system that can withstand even a lorry bomb – and have independent technical accreditation and live testing video evidence.

Specifically in terms of high wind loading, our large-span systems are in place in various parts of the world. For example, advanced Wrightstyle roof glazing was installed at a highly-sensitive HSBC data hub in Hong Kong, a typhoon area, in a building that is critical to the bank’s operations in the Asia-Pacific region. We have plenty of other examples.

In recent years, the USA has spent over $4.5 billion on new or updated weather forecasting systems, including new satellites and higher-resolution imagery to better track hurricane movement and therefore provide more accurate data – a significant investment that has probably saved a great many lives across the eastern seaboard.

No doubt US federal authorities, pressed by the insurance industry, will again be looking at tightening building and other codes to see how the effects of future extreme weather events, on both people and infrastructure, can be further reduced.

However, the best forms of protection are often the simplest; primarily, to go to and remain in a safe place. Today’s high-specification glazing systems are able to provide an integral part of that protective envelope and, despite the carnage a hurricane can inflict, have probably saved a great many lives.

600450

600450

Add new comment