Date: 22 February 2024

CVGLASS is distinguished by its commitment to quality, innovation and customer satisfaction, backed by a solid infrastructure and the adoption of cutting-edge technology to stay ahead in the competitive glass market.

Formed in 2012 from the merger of the companies Viplasa, Alvisan and Cristalde, CVGLASS is consolidated with a rich history in the glass sector, making the most of human and technological resources to become a benchmark in the glass market.

With two production centers located in Polígono Industrial Juncaril and Vegas del Genil, both in Granada, CVGLASS has a total surface area of 6,000 m2 of facilities. This robust infrastructure supports its production capacity and its commitment to quality and innovation.

CVGLASS has recently invested in new TUROMAS cutting machines to meet the growing demand for glass. These machines stand out for their cutting precision, reliability and close and efficient technical service. The easy and simple operation of these machines, together with their low material breakage rate, make them the perfect choice for CVGLASS’ needs.

Turomas talked to Francisco Díaz and Mariano Martín, managers of CVGlass, about their business, their objective and the development of the Spanish market.

- What is CVGLASS?

CENTRAL VIDRIERA GRANADINA, S.L. with its commercial name CVGLASS, is a historical company with a great trajectory in the glass sector, born from the merger of three leading companies in the area of Granada.

Our large production capacity, technological resources, and the wide experience of our staff position us as a reference in the regional glass sector, adapting to the market with a continuous evolution.

Within our glass storage and handling activity, our main activity is the manufacture of insulating glass (double glazing) under the SGG CLIMALIT® brand, with a wide range of products to comply with current regulations.

- How did the need for the new TUROMAS cutting machines arise?

Due to the continuous market demand for standard laminated and coated laminated glass, the latter is increasingly used and the last incorporation were two laminate cutting tables with pickling system in each cutting bridge and a monolith with automatic pickling system, connected in line with each other, so that we get a better operation and performance.

- Which TUROMAS machine models have been installed?

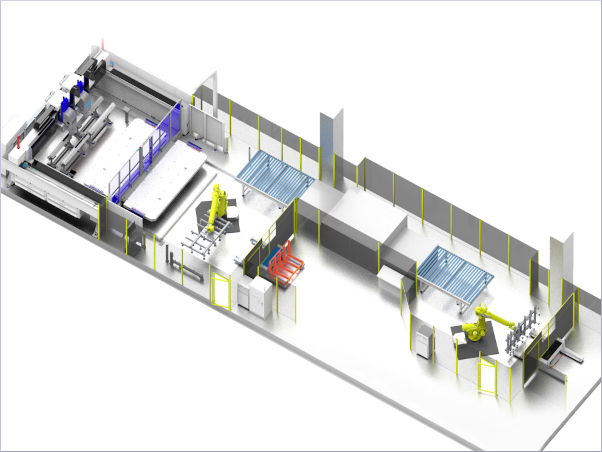

The latest models of this year have been, LAM 505T, LAM304, RUBI306TC, on the other hand, we have LAM506SX, RUBI506, Aerial Loader, etc. …. In summary, we have 2.000 m2 of a set of machinery, all from TUROMAS.

- Why are these machines the best for CVGLASS and what would you highlight about them?

Firstly, for the technical service, close and national, secondly, for its range of models that adapt to our needs, and finally for the confidence and attention of so many years.

The easy and simple to use operation, cutting precision and low material breakage rate, and the reliability of the computer components.

With a deep-rooted history, investment in cutting-edge technology and a commitment to quality and customer satisfaction, CVGlass will continue to lead the way in the glass industry.

600450

600450

Add new comment