Others also read

The ECO Scanner has established itself on the market as an extremely powerful system.

Please join Viprotron in welcoming their newest team member: Scott Knisely.

The Polish company Q4GLASS now utilizes a LineScanner from SOFTSOLUTION, to testify Quality 4 GLASS in Koszalin, near the Baltic Sea in the northernmost tip of Poland.

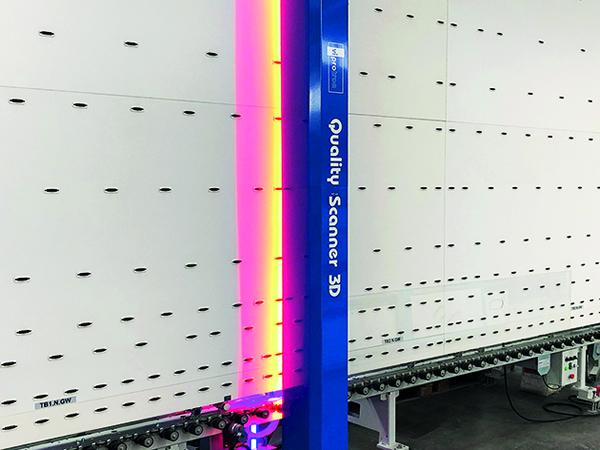

The Quality Scanner automates your glass quality control and brings it to the highest standard.

The existing furnace will be enlarged by HORN® and equipped with new heating equipment and safety control.

For the production of coated glass products, Şişecam Trakya relies on fully automatic inspection with ISRA VISION P2 (PowerPlate) - Coating – thereby raising both customer satisfaction and efficiency.

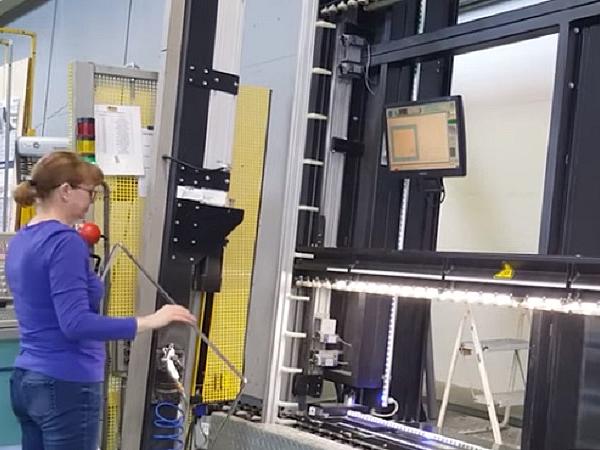

LineScanner - high precision dimension control of glass for drill holes, cutouts, notches and much more!

The furnace is designed in appliance with the most advanced technology and a maximum melting output of 290 t/d to produce either 290 t/d flint or amber glass or 280 t/d green glass.

New agent for France, Algeria, Tunisia, Morocco and DOM-COM

CulletScanner with tilt-function - new Video available! Automatic fragmentation image analysis with optional polarization function.

How can product quality and production processes in various glass applications be optimized by using Optris IR cameras and pyrometers?

Forel has released a special version of its “High Tech” IG line, equipped with a flexible spacer applicator and a “Hot Melt” sealing robot.

What needs to be considered when using infrared thermometers, IR cameras and our new glass inspection system in different glass applications?

After extensive tests and research Tryba has decided to use the reliable Quality Scanners from Viprotron.

Thanks to the latest developments, the LineScanner Management Console and artificial intelligence are now used to optimize processes.

Even in the segments that were hardest hit by the coronavirus crisis the indicators are looking more positive again.

Today 274 employees work for the Turkish company Tamcam Oto Cam Sanayii A.S., checking anisotropy and edge stress with a horizontal LineScanner from SOFTSOLUTION.

Every customer project is unique and this is how we see the cooperation with our customers who trust in automated quality assurance systems from SOFTSOLUTION.

Meet SOFTSOLUTION North America Inc. virtually and learn more about our automated quality assurance systems (LineScanner, CulletScanner, VirtualDigitizing).

This year in April HORN received the order for the repair of furnace 1 for the plant in Steinbach am Wald, which is an 82.8 m² end fired furnace.

As an innovative company, SOFTSOLUTION specializes in automated quality assurance systems, electronic image capturing and software development in the glass industry for more than 15 years.

Since the beginning of February, employees of HORN Glass Industries AG have been on a construction site in Orizaba, a city east of Mexico City, in order to set up and commission a glass melting plant for its customer SIVESA.

Starglaze was looking for a reliable, state-of-the-art glass quality inspection system. The solution: LineScanner, SOFTSOLUTION's all-in-one system that inspects glass lites with extreme precision for all quality and surface defects.