Others also read

eLstar Dynamics on episode #11 of Step Change 2023 series, presenting their technologies.

2MH Glas on episode #10 of Step Change 2023 series, presenting their technologies.

Read more about the company and watch the interview at Step Change 2023 Base Camp in June.

On November 3, 2023, the new Engineering Center was opened at the LiSEC site in Seitenstetten.

Do you have large production of glass to process? The solution is a custom CMS system!

LiSEC will be showcasing its cutting-edge glass processing technologies and state-of-the-art machinery at booth #2831.

Read more about the company and watch the interview at Step Change 2023 Base Camp in June.

A partnership with LiSEC for a greener future

Read more about the company and watch the interview at Step Change 2023 Base Camp in June.

Predari Vetri's journey to customer-centric excellence and innovation in insulating glass production.

Read more about Volframi and watch the interview at Step Change 2023 Base Camp in June.

Read more about the company Peafowl Plasmonics and watch the interview at Step Change 2023 Base Camp in June.

Schiatti Angelo Srl is gearing up for Vitrum 2023, scheduled to take place from 5th to 8th September at Fiera Milano Rho.

Don't miss the CMS Glass Technology's Open House on 8th and 9th September 2023 at the CMS headquarters in Zogno.

Schraml Glastechnik GmbH, a member of the LiSEC Group, is proud to announce the launch of the 8th generation topDRILL glass drilling machine.

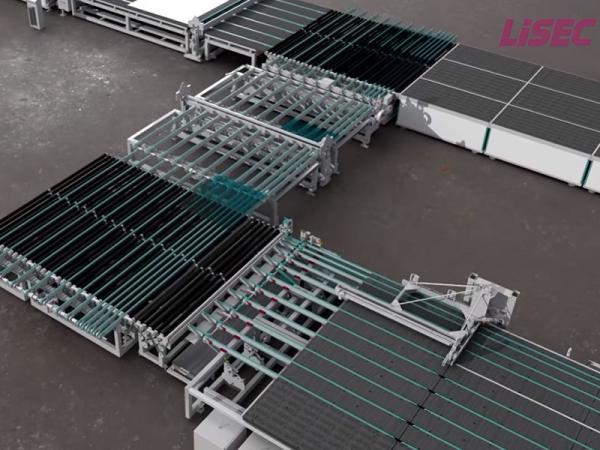

Laminated Glass Production with LiSEC Machines: Speed Assembling Mode

How high-quality insulating glass is produced with LiSEC machines in Nord Rostock.

The LiSEC PlusLam is a laminated glass line equipped with sophisticated machines and sophisticated lamination technology.

Adelio Lattuada S.r.l., in collaboration with their local agent P.A.L. Glass Machinery, has successfully completed a new installation in the UK.

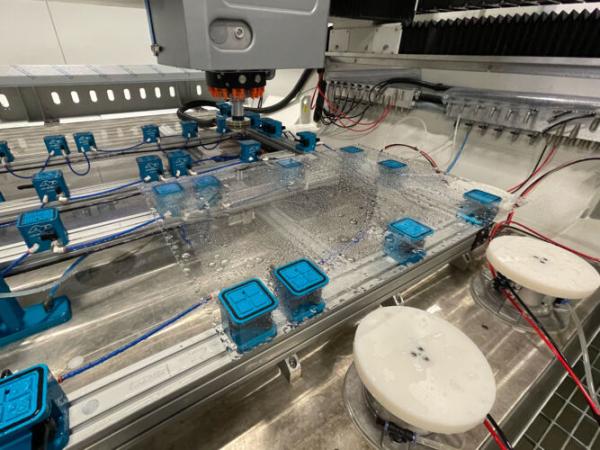

The one-by-one mode is especially suitable for the series production of small glass at high speed with only one person. In addition, there is less foil waste due to the waste optimisation.