Date: 17 October 2023

The Swedish company Glasgruppen can look back on three decades of experience in the glass industry. Stina Wollenius, the owner and sole shareholder of Glasgruppen in third generation, believes that the focus on a deep customer relationship and doing business in a sustainable way is the secret to success, also in the future. Due to the successful long-term strategic partnership with LiSEC, Glasgruppen decided to invest in a new TPA line made in Austria.

ABOUT GLASGRUPPEN

Glasgruppen is one of the leading Swedish glass processing companies that consists of the family-owned companies Martin G Anderson in Örebro, Klaes Jansson in Stockholm and RB Glas & Plast in Gothenburg. The firm counts more than 120 employees in total, of which most work at the Örebro site. Within Martin G Anderson’s walls, glass undergoes cutting, tempering, and processing. The company's product range is wide, encompassing energy efficient insulating glass, fire resistant glass, processed glass, and design glass for various construction needs. Notably, insulating glass is their most popular product. The facility in Örebro supplies the company's largest functional glass products, featuring energy coatings, sun protection, and other specialities. With an annual turnover of around 25 million EUR, Glasgruppen primarily delivers to the Nordic region. The company’s clientele spans a wide spectrum, serving everyone from individual glaziers to big façade construction companies.

GLASGRUPPEN’S IDEA OF A MORE SUSTAINABLE MARKET IN THE FUTURE

Owner and chairwoman of the board Stina Wollenius is the trendsetter when it comes to sustainability in the glass industry and hopes to inspire big players to foster the importance of sustainability. Besides focusing on TPA material for IG production, shifting from bigger to smarter glass products is key. As an example, embracing the usage of European standard size for glass in construction projects can drastically reduce waste from 20 % to as low as 2 % in comparison to non-standard-sizes. In order to stay competitive in the future, automatization will be of great importance. Also, upcoming trends like glass with integrated sun panels, bird-safe glass and resource saving glass have big potential in the “greener” future.

COLLABORATION WITH LISEC

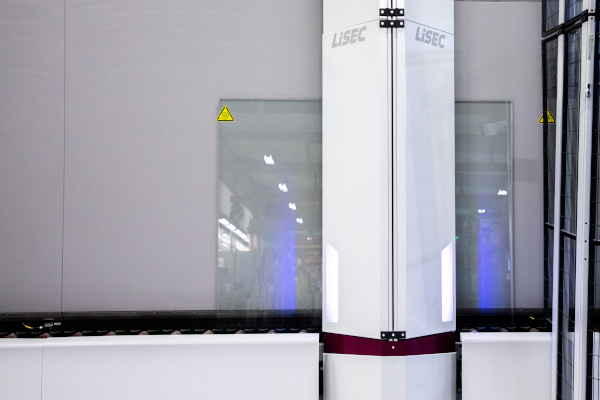

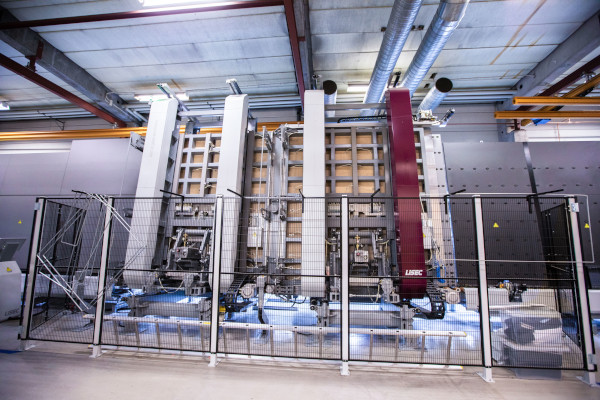

The partnership between Glasgruppen and LiSEC has roots reaching back to the 1970s, making the firm one of LiSEC’s first customers in the Nordic region. This long-term collaboration began through initial contacts at the very first glasstec fairs and has since blossomed into a synergistic relationship. In Sweden, the brand LiSEC is very well known, especially for its insulating glass machinery and cutting tables. Thus, Glasgruppen’s Martin G Anderson has incorporated LiSEC cutting tables for float glass (GFB) and laminated glass (VB), a grinding machine (KSR) and a bender (BSV-45ANK) into their operations. The latest investment was a TPA line.

“The reason why we buy LiSEC for generations is the high quality and long lifetime of the machinery, as well as the reliability of the output and the great service.” (Stina Wollenius, Owner of Glasgruppen)

Glasgruppen speaks highly of their cooperation with LiSEC, emphasizing the exceptional service, quick response times, and close collaboration with the sales team. This level of support fosters a sense of trust and reliability, allowing Glasgruppen to focus on their operations without concerns about machinery and technical support.

HOW THE LISEC TPA LINE AT MARTIN G ANDERSON FITS INTO THE SUSTAINABLE STRATEGY OF GLASGRUPPEN

Glasgruppen thrives on its commitment to service excellence, nurturing strong customer relationships, and minimizing its environmental impact. The company's dedication to fast deliveries, high-quality products, and low carbon emissions sets it apart in the market. For instance, in all Glasgruppen factories glass waste is 100 % recirculated and all trucks run on renewable energy. In general, the company has reduced approx. 98 % of their own emissions and are working on the approx. last 2 % as well. The Swedish company thinks that TPA is the technology with the biggest future potential and also the most sustainable choice when it comes to manufacturing insulating glass units. The owner and chairwoman Stina Wollenius is a big supporter of the TPA technology because it not only extends the lifetime of products and is very flexible when it comes to spacer sizes but also contributes to the circular economy. TPA spacers facilitate the recirculation of products by leaving no metal contamination, unlike other spacer types, enhancing their potential for reuse and reducing overall environmental impact.

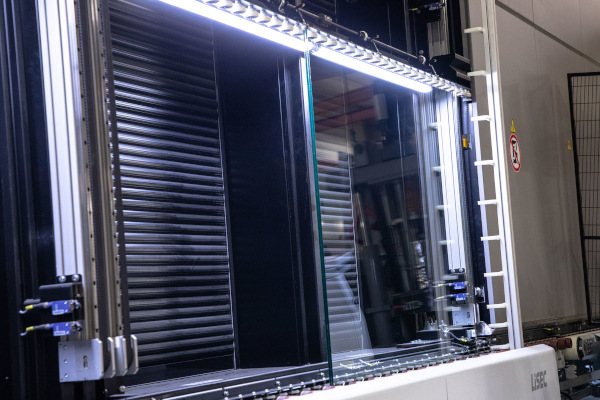

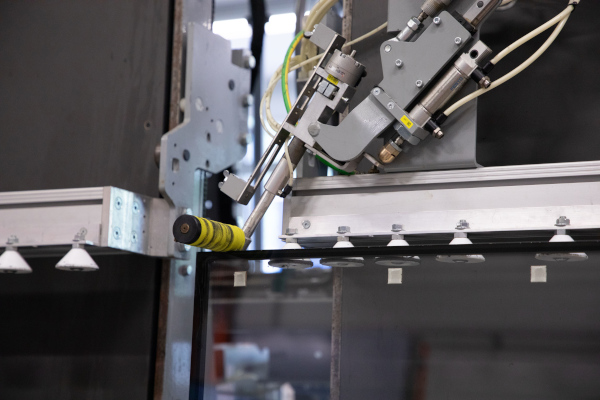

With the clear goal of using TPA technology Martin G Anderson looked for new solutions. In an extensive decision-making process, the company decided for the LiSEC TPA line. Martin G Anderson knew the strengths and production restrictions of the previous line very well and with the offered TPA line LiSEC was the only one to solve the issues of the old line and created the best solution for Glasgruppen. The LiSEC TPA line at Martin G Anderson is able to produce quadruple insulating glass units with a thickness of up to 100 mm and a weight of up to 350 kg / running metre The line was individually constructed to fit the space requirements at Martin G Anderson. The insulating glass line has a rotating inclination adjustment station (NWLD) built in to turn the insulating glass units by 90°. The heart of the LiSEC insulating glass line is the TPA-A, which is a fully automatic system for applying thermoplastic spacer bars. The LiSEC TPA allows the highest flexibility by seamlessly switching between different dimensions of the glass and between different spacer widths without the requirement for a waiting time. The LiSEC AGP-A integrated into this line is a high-end gas filling press for fully automatic gas filling, assembly and pressing of insulating glass units. The LiSEC AGP-A is perfectly suited for processing thermoplastic spacers because a belt drive is used on both the fixed press plate and the moveable press plate. The LiSEC VFL-1F is a system for sealing insulating glass units with two-component sealants. The perfected build-up of this system guarantees a high degree of process reliability and top corner quality, even for units with a high weight.

More information about the LiSEC TPA-A: https://www.lisec.com/solutions/individual-machines/detail/thermoplastic-spacer/tpa

More information about the AGP-A: https://www.lisec.com/solutions/individual-machines/detail/pressing/agp-a

More information about the VFL-1F: https://www.lisec.com/solutions/individual-machines/detail/sealing/cleanseal-vfl-1f

600450

600450

Add new comment