Date: 27 July 2020

Piramal Glass Limited (formerly known as Gujarat Glass Pvt Ltd) is a global specialist located in India to design, produce and decorate of premium glass packaging for pharma, cosmetics, perfumery, skin-care, food, and beverage industry. Piramal Glass is one of the largest players in the Asian premium glass-packaging segment.

The company has four manufacturing facilities: one in the USA, one in Sri Lanka, and two in India (Kosamba and Jambusar) with an overall capacity of 1465 tonnes per day (tpd). The Kosamba facility has six furnaces. Piramal Glass produces there USP Type I, II and III glass bottles / vials for the pharmaceutical industry, Type III glass bottles for cosmetics & perfumery industry and also feeder-coloured bottles in various shades. The Kosamba plant contains also a dedicated facility for Type-I borosilicate glass for moulded pharmaceutical glass packaging and a dedicated facility for premium cosmetics & perfumery glass bottles.

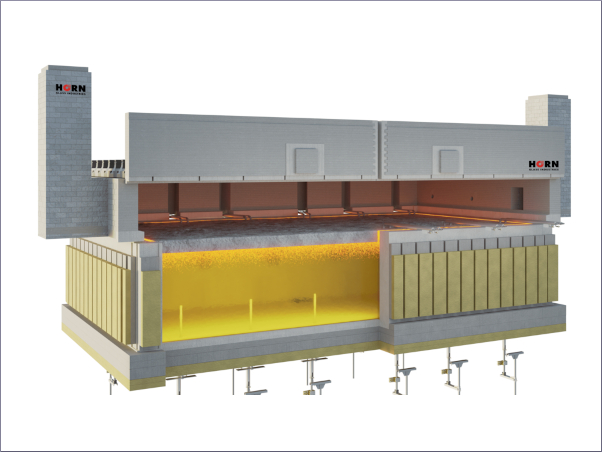

In May 2018 HORN Glass Industries AG received the order from Piramal Glass to redesign their existing 100 tpd furnace for the premium cosmetics & perfumery bottles. The order comprised design drawings and some equipment (combustion-, boosting and reversing system) for the furnace with 8 forehearth lines in total.

HORN supplied the end fired furnace designed with appliance of the most advanced technology to save energy, reduce emission values and extend furnace life. The furnace is designed with a melting area of 82.8 m² to produce up to 145 tpd in total.

HORN had been awarded to supervise the whole furnace repair works. However due to the Covid-19 pandemic the supervision and commissioning was done by Piramal alone with remote assistance of HORN experts. The new 145 tpd furnace was put successfully in operation in June 2020.

600450

600450

Add new comment