Date: 8 December 2025

With over 120 years of glassmaking tradition and an unmistakable sense of design, RITZENHOFF is today one of Germany’s most renowned glass manufacturers. The company stands for high-quality drinking glasses and design objects Made in Germany, appreciated by customers around the world.

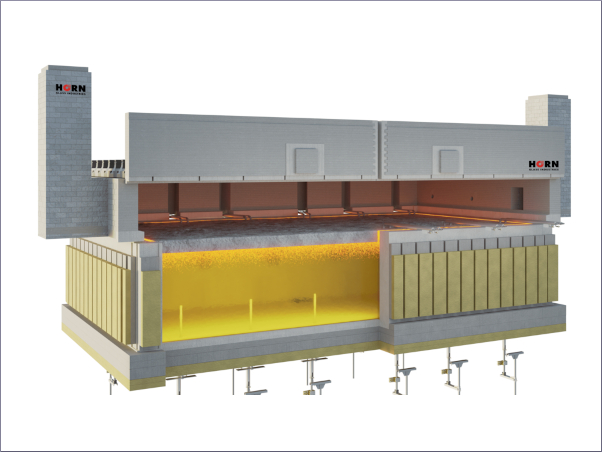

HORN Bau & Service GmbH, a subsidiary of HORN Glass Industries AG, was commissioned to perform a hot repair on one of RITZENHOFF’s glass melting furnaces in Marsberg. The work took place in September 2025 and was completed successfully and on schedule after just 21 days.

To carry out the repair, the entire 80 t/d glass melting furnace was completely drained in order to perform extensive work on the doghouse, throat, and distributor.

A key challenge was to plan and coordinate the process so that all steps would interlock seamlessly, without cooling down the furnace. Since several areas were being worked on simultaneously, precise coordination among all teams was essential to ensure timely completion. To meet the tight schedule, the repair was carried out around the clock in multiple shifts.

The repair process consisted of several coordinated steps: After the controlled draining of the glass, the heavily stressed throat and distributor were completely dismantled and rebuilt. At the same time, another HORN team renewed the doghouse palisades, including the corners, and plated various other critical areas.

Throughout the repair, continuous endoscopic inspections were conducted to assess the scope of work and ensure HORN’s high quality standards. Following the successful heat up carried out by HORN, the furnace was able to be restarted after just a few days, with the forehearth remaining hot throughout the process.

We wish RITZENHOFF good glass all the times and look forward to further projects.

A heartfelt thank-you goes to all subcontractors involved, and especially to the RITZENHOFF team for their outstanding cooperation and smooth collaboration.

600450

600450

Add new comment