Date: 16 November 2017

LiSEC, a pioneer in the development and manufacture of equipment and machinery for flat glass processing, has revolutionized logistical handling of insulating glass units due to a sophisticated handling system.

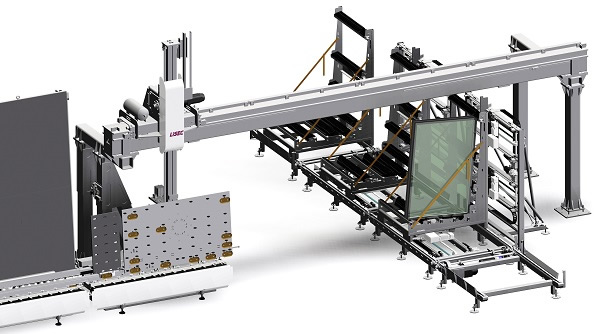

This logistics solution, which consists of a gantry crane facility (UTS-B) and a mobile unit buffer (MEB-B), improves quality, saves time, resources and money.

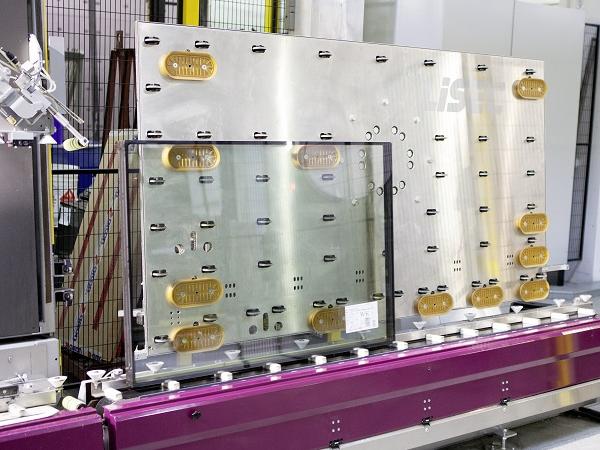

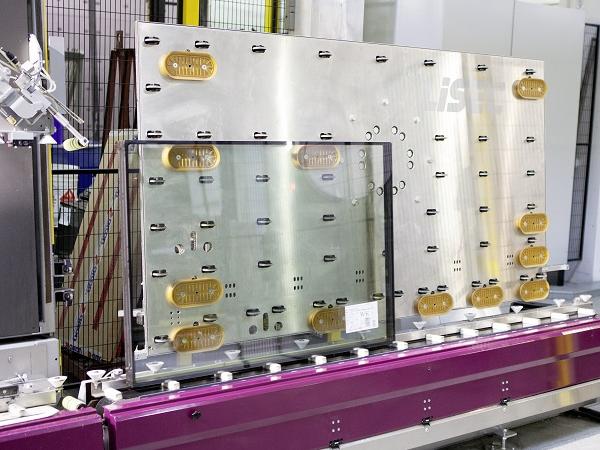

The automatic gantry crane facility (UTS-B), which is arranged downstream of a LiSEC sealing machine, is particularly suitable for unstacking of freshly sealed insulating glass units with fixed or flexible spacer systems, with particular advantage for thermoplastic spacers.

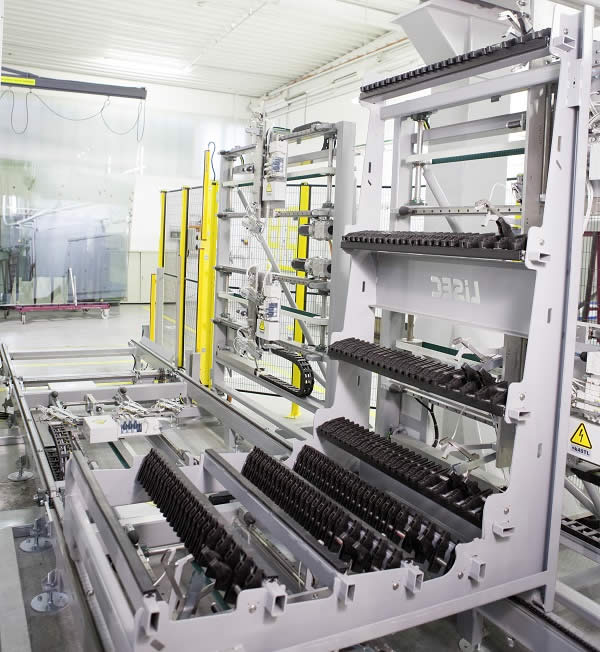

The glass units are sent out in the direction of the line and rotated from horizontal to upright position before being sorted into the mobile buffer system (MEB-B). The mobile unit buffer serves for manual or automatic unloading, curing and transporting of insulating glass units. Further re-sorting is therefore no longer necessary.

Improved production flow and quality assurance

The production flow is significantly improved by automatic unloading and sorting. The insulating glass unit is removed from the suction plate without compressing it. Support fingers located at the bottom and side edges prevent the glass sheets from slipping. This guarantees compliance with quality and tolerances.

Consistent product quality

Fixation of glass sheets on the transport rack MEB-B takes place without compression due to individually adjustable spacer brackets. This ensures a high-quality standard of insulating glass units - especially with thermoplastic spacers.

Less transport costs

The transport of insulating glass units in upright position saves space and a possible manual unloading in any order ensures flexibility. The MEB-B is always optimally loaded due to flexible spacers. The number of compartments varies depending on unit thickness.

Loading and packaging is easy and fast. The mobile unit buffer is optimized for truck transports and saves costs. A truck can be loaded with up to 18 filled or 36 empty MEB-Bs.

Curing, without re-sorting, directly on site

The unit buffers are specifically designed to allow the thermoplastic spacers to cure directly at the unit buffer. This saves space, time and money.

Tracking system

The individual transport racks can be coded for each customer. The new LiSEC „Delivery Tracking“ simplifies logistical handling, provides transparency and saves time in the logistics process.

Individual, modular design

The entire modular system can be adapted to the customer's space requirements and is compatible with almost all current LiSEC lines.

600450

600450

Add new comment