Date: 6 April 2016

There are hardly enough buzzwords to introduce our new TWIN Laser Micromachining Station!

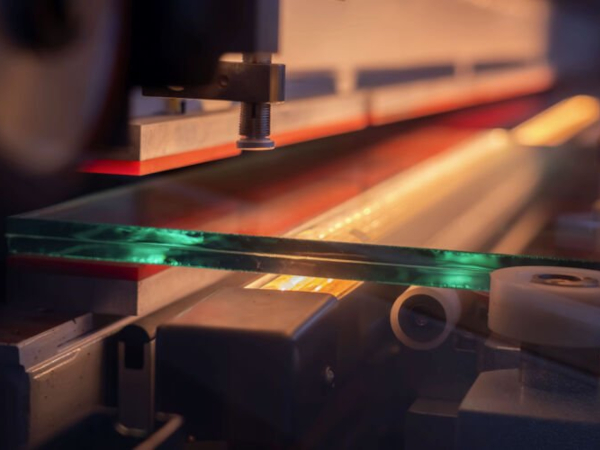

Equipped with our innovative PearlCut process the TWIN machine allows to cut glass in any shape, without debris and with "cutting edge edges".

The dual head design allows to integrate additional processing steps, such as thin-film ablation of ITO or other conductive oxides, metals or semiconductors. The super precise all granite platform allows to integrate up to 3 laser sources in one machine.

CCD camera allignment for fiducials, automated calibration and a powerful and easy to use import routine for CAD files make the TWIN the versatile solution for your micrmachining needs.

Contact us to learn how our modular system can help solve your micromachining needs.

600450

600450

Add new comment