Date: 9 August 2024

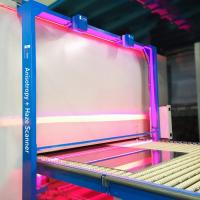

By incorporating radar technology to measure glass levels, HORN has developed a very precise technology in glass production. With this new contact-free method, HORN has guaranteed its customers high accuracy in glass level measurement for three years now.

A constant glass level in the melting end is a very important control component in the glass melting process. Glass level variations influence the steady operation of the furnace and have a significant influence on the gob weight. The high measuring accuracy of the HORN HRD-BEAM allows the precise control of the glass level together with all common charging machines.

HORN´s contactless glass level measurement provides an impressive measuring accuracy of +/- 0.1 mm or even better and reduces all maintenance work to a minimum because no mechanical moving parts are built in. This radar technology does not only set new standards in the glass industry, it also leads to enhanced production quality, lower error rates and contributes to a more sustainable and profitable manufacturing process.

The water-cooled radar sensor is acting like a transmitter / receiver module in one unit. Radar waves are sent to the glass surface and are reflected by it. The glass level will be calculated according to the time between the emission and the reflection of the waves. The measurement device will be installed on top of the distributor or forehearth (for a container glass furnace) or on top of the working end (for a float glass furnace).

FEATURES

• Simple opening for measurement in the distributor / working end crown

• Easy installation of the system; no welding necessary

• Network connection; remote access easily possible

• Measurement independent of glass colour

• Minimum maintenance effort

• No special housings / safety fences etc. necessary

• No influence by cooling air

• No spill air necessary

Seven systems, which were sold in 2023 and 4 systems which have been sold so far in 2024, are proof of customers' trust in HORN technology.

Join us at glasstec 2024 to find out how Radar Measurement can benefit your furnace project.

Further information at Glass Level Measuring (hornglass.com)

600450

600450

Add new comment