This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- Alexander Pauli

- Dominik Offereins

- Geralt Siebert

University of the Bundeswehr Munich

Abstract

Due to their mechanical and optical properties UV-curable adhesives, available in different compositions, are considered very promising in structural glass design. Especially in the field of transparent facades, they could play an important role. However, a product with wide use in glass construction is still missing; therefore, research within this field is needed. This work investigates the numerical modeling of two different UV-curing acrylate adhesives in terms of the bulk material and in the application as point fixing: One very stiff adhesive, which in the following is referred to as “Acrylate 1”, and one softer adhesive, which is used as an interlayer for laminated glasses and in the following is referred to as “Acrylate 2” (cf. [2]).

Based on the experimental data, provided in [2] in the form of DMTA and uniaxial tension tests, an analysis of the material behavior takes place for both materials [1]. Acrylate 1 shows linear elastic behavior in the uniaxial tensile test with failure at an elongation of about 1%. Furthermore, according to the DMTA measurement results, it still exhibits extraordinary stiffness even in the range of temperatures of 80°C. Acrylate 2 shows a strongly rate-dependent behavior in the uniaxial tensile test with failure in the range of large deformations. According to the DMTA data, the stiffness at low temperatures (below 0°C) is a factor of 4 lower than that of Acrylate 1 and becomes noticeably softer as the temperature rises. At 80°C, Acrylate 2 has only 1/10 of the stiffness of Acrylate 1.

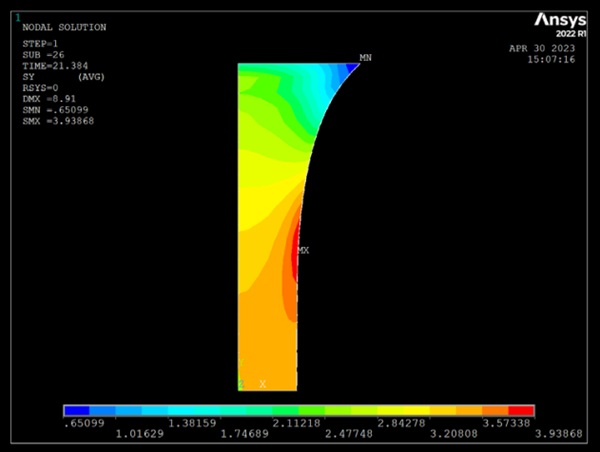

Based on the measurement results, a linear elastic material model is used to describe Acrylate 1. The influence of temperature is considered via a temperature-dependent modulus of elasticity. Acrylate 2 is described with a model of finite, linear viscoelasticity. The temperature dependence is taken into account via a time-temperature shift principle. Furthermore, a von Mises failure hypothesis is constructed for both materials based on the fracture stress in the uniaxial tensile test. The failure criterion is thereby reduced with respect to temperature.

The material models are compared and validated against the uniaxial tensile tests.

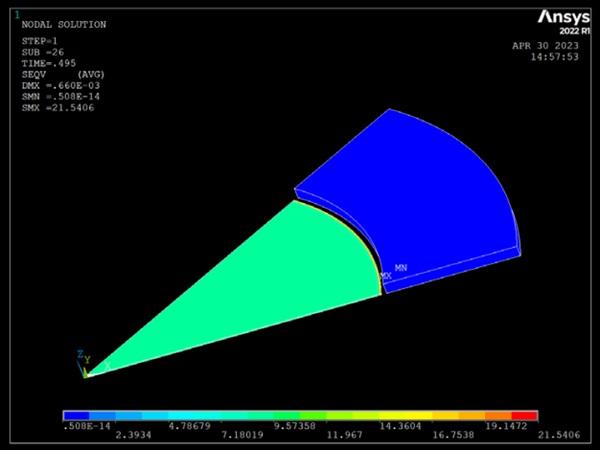

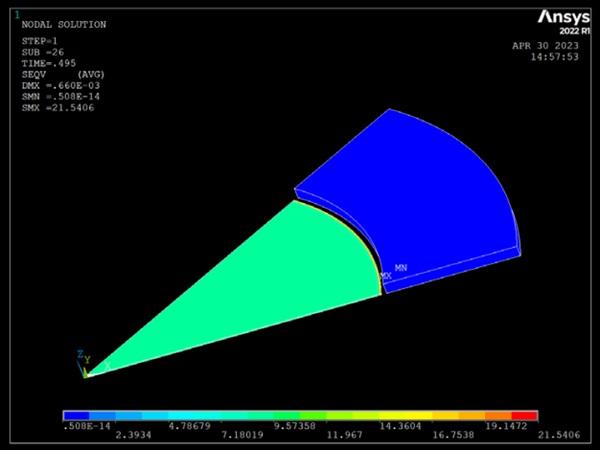

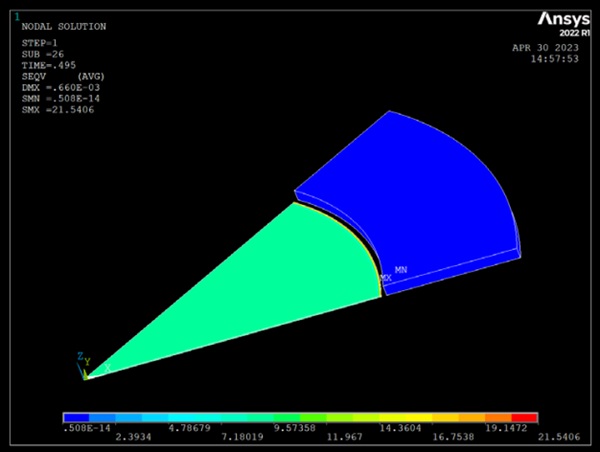

Subsequently, a point support constructed with two adhesive bonding’s to account for a redundant load bearing is simulated. The adhesive bond consists of an inner circular surface with a layer thickness of 0.1 mm and a diameter of 54 mm, made of Acrylate 1, and an outer ring with a width of 12 mm and a thickness of 1 mm, made of Acrylate 2. The inner layer is to transfer all loads, the outer layer is to protect the inner layer from environmental influences on the one hand and to provide additional safety in case of failure on the other hand.

Finally, the suitability of the glued point support and the used materials is discussed and the need for further research is pointed out.

This research paper is funded by dtec.bw – Digitalization and Technology Research Center of the Bundeswehr. dtec.bw is funded by the European Union – NextGenerationEU.

References

[1] Kraus, M. A., and M. Niederwald. "Generalized collocation method using Stiffness matrices in the context of the Theory of Linear viscoelasticity (GUSTL)." Tech. Mech 37.1 (2017): 82-106.

[2] Offereins D., Pauli A., Siebert G.: Evaluation of the suitability of UV-curing acrylate adhesives in structural glass applications by DMTA. Glass Performance Days (2023)