Date: 13 May 2011

For machinery companies over the last two years, it has been one of the toughest times ever; however for Hegla with its strong pedigree and viable reputation for quality and excellence, it has been a time to batten down the hatches and make sensible adjustments rather than drastic slashes enabling product development to take place for when times improved. With a lot of manufacturers now taking stock and evaluating the best place for investment to ensure they make a mark and take a lead position, it’s clear to see how hard the UK’s glass manufacturing industry has been hit by this recession. There have been stories of doom, gloom and despondency everywhere, three-day weeks, redundancies and of course, administrators crashing in which have all dominated not just the trade press but the whole UK media for months.

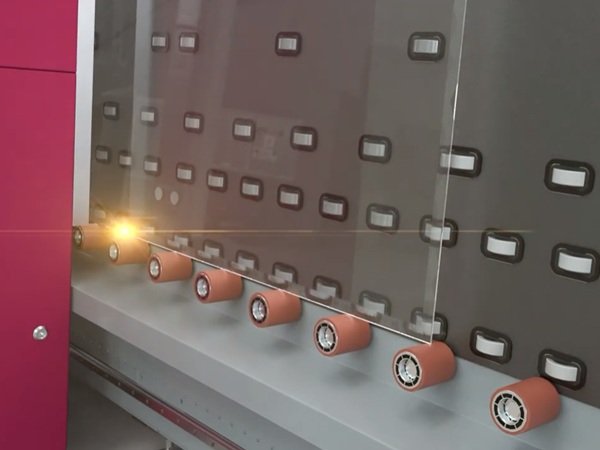

Now the UK is officially out of recession apparently, so it is important for the survivors and those who took hard hits to ensure that any investments made will ensure their businesses will prosper again. Hegla has worked diligently to ensure that quality product development continued whilst the excellent support services that are synonymous with the company were maintained. Recessionary times hit everyone hard however the further development of the Galactic Linear Drive cutting range now ensures that all manufacturers can make sound investment in their production facilities that will guarantee a return on investment which will last for 10 to 20 years. The unique qualities of the Galactic and the Galactic Econ range come in the form of a magnetic drive rather than a rack and pinion system which gives an accuracy of +/ -0.1 mm. With higher speeds (200-300m/min) and more importantly excellent acceleration (typically 5m/s² - 14m/s²) there will be an increase in output or a time gain for other applications such as Laser Marking of the glass.

Additionally being a magnetic linear drive this means that it does not wear in the same way as electro/mechanical systems which are on the market enabling Hegla products to offer a longer service life. Over the last five years Hegla worked tirelessly on this new product development, having conceived and developed the whole concept of Linear Drive Glass Cutting Tables. Linear drive has subsequently evolved to become globally one of the most highly sophisticated and reliable cutting systems on the market today with various combinations of machines installed at major companies across Europe and North America All Hegla Galactic tables are water cooled and can have twin cutting heads and twin soft coat edge deletion which means trim cuts are not required. As with all cutting tables in the Hegla range, both Galactic systems can be installed with a Laser Marking System.

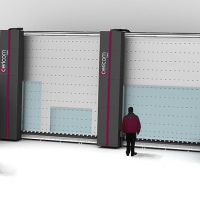

These highly advanced machines enable glass to be marked with batch information and racks numbers for toughened glass, logos as well as other future applications which are currently under test. This ensures that the correct information is placed on the glass at the cutting stage, completely eliminating human error and reducing time considerably which normally occurs with this process. The range of Galactic linear drive tables caters for all areas within the flat glass industry, with specific models having been developed for glass processors that provide various options including all in one tilt tables, free-fall and tables with automatic loading.

Most recently this new linear drive system has revolutionized high precision cutting on small instrument type glasses with very high accuracy for specialist component manufacturers. As glass companies look to invest in the long term it is essential that they evaluate the financial cost savings that can be made using equipment that has been developed for tomorrow’s market. Hegla has consistently evaluated the existing and future trends to ensure where at all possible companies will yield profit. Steve Goble specifies, “During the recession, businesses were and still remain under extreme pressure to cut or keep down costs and as they now emerge from one of the most dramatic downturns in living memory, it can be easy to keep cutting back and even withhold investment which is desperately required for growth.

While the recovery remains fragile and confidence continues to be hesitant, there has never been a more important time to evaluate exactly what quality guarantees mean. With Hegla this is never compromised as customers will attest regarding the entire range”. He continues, “At a time when survival is the priority for many manufacturers, it is crucial to make the correct choices and most appropriate business decisions based on current conditions and more importantly future trends as the potential financial implications could have a significant impact on the speed of their recovery from the recession.” Hegla’s commitment to provide excellence as standard has never faltered, with the research and development department keeping an eye on future trends and industry standards. With this in mind the Galactic range was developed for increased speed, acceleration, and Laser Marking.

There are already two installations with Laser Marking in the UK currently, one being on a Galactic cutting table for high speed applications whilst the other is on a combination float/laminated which is used as a multipurpose machine. Steve Goble concludes: “Companies need a way to cut through the chaos and avoid pitfalls by investing in quality not hearsay. Hegla’s systems are always tailored to suit not just your business needs today but for whatever the emerging market brings over the next few years. With Hegla, quality is never compromised”

Add new comment