Date: 13 July 2011

Triple glazing is relatively uncommon across the UK with most homeowners still getting to grips with the WERs and A rated windows. The triple glazing product will probably become more important to the consumer as today’s governments continue to place environmental issues and carbon emission reductions as priorities.

Before investing consumers will naturally want to know a little on the benefits over double glazing and measuring energy performance against triple options. The improved insulation and sound reduction factors will inevitably attract buyers, giving them the incentive to invest in the more costly product that will be higher than standard double glazing. For manufacturers however there are a number of major considerations to also evaluate when making the decision to diversify into triple glazed unit production. The Hegla team has been considering the effect this will have on manufacturing methods and the market as it changes, to ensure that any equipment developed will not only help customers to meet the exacting requirements of today’s legislation but also will accommodate the industry standards that will inevitably be introduced within a short period of time. Triple glazing, undeniably, will be the hot topic of the moment for some time to come , as many in the industry speculate about the level of investment that will be required to meet production standards. Undoubtedly, if triple glazing becomes a legislative requirement there will be a need to accommodate 50% more glass into the production process and production control within sealed unit assembly will become much more complex.

However there is a broader picture to consider which Hegla has been evaluating and incorporating into its product range.

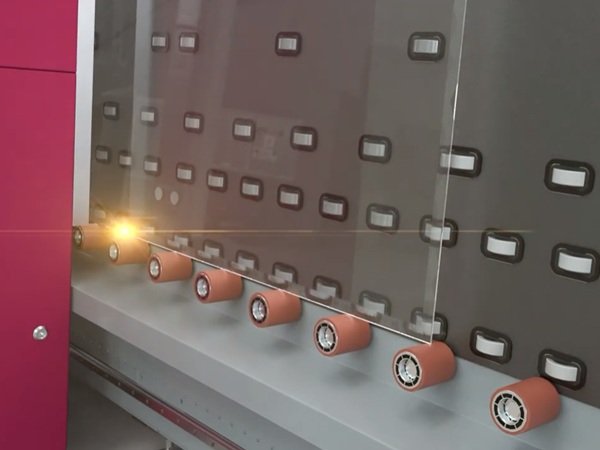

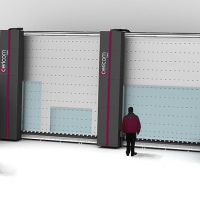

Faster machinery development in terms of products such as the Hegla Galactic range of Linear Drive Cutting Tables will give manufacturers real time benefits. In relation to triple units and toughened glass the extra function of laser marking enables the glass to be marked automatically before it is cut which automates the entire procedure, eliminates human error and complements customer existing production control software. With toughened glass production there is usually a unique identification applied to the glass as a post process to cutting and breaking with a white marker pen which is not always applied 100% accurately, takes time and can leave ghosting on finished sealed unit products; however with the Hegla system these issues are eliminated. Other obvious advantages that will assist in the production process include the elimination of paper and label wastage. Hegla is continually looking at ways to move forward with cutting technology and the Galactic range of water cooled linear drive tables with Laser Marking System are ideal for triple glazing production and provides a cost effective, fast, reliable and relatively inexpensive means to produce glass panes that can be edge deleted, laser marked and cut in a similar time scale to a standard cutting table.

”The typical glass factory in the UK has no space and usually only room for one cutting table. How can the extra glass cutting capacity therefore be created for the same factory footprint? We can assume that excessive work hours or moving to a bigger factory with more machines and a larger workforce would not be the ideal solution. As the industry moves forward to accommodate innovation, Hegla is leading by example in providing manufacturers with so much more than glass cutting solutions. The speed, accuracy and acceleration of the Hegla range of equipment not only saves time and money but ensures that faster turnarounds can be guaranteed. The ability to diversify into the triple glazing market is in fact a simple and reliable process which thanks to Hegla will reap both financial and real time benefits. The laser marking system has been meticulously designed to cater for the changing needs of the market. It is also possible to retro-fit the Laser marking system to most existing Hegla cutting tables The advantages of triple glazed units will eventually lead many homeowners to decide that it is worth the investment. This industry has to be able to respond quickly when the market changes and legislation is introduced, ensuring that it can meet consumer requirements with sufficient volumes. Additionally the constricting standards relating to Part L of the Building Regulations, mean that triple glazing could become compulsory for more than the domestic sector. Without doubt product innovation is required to support the changes and the market as a whole, along with the development of new process technologies that reduce production costs for manufacturers if success is to be achieved.”

Add new comment