Date: 14 October 2024

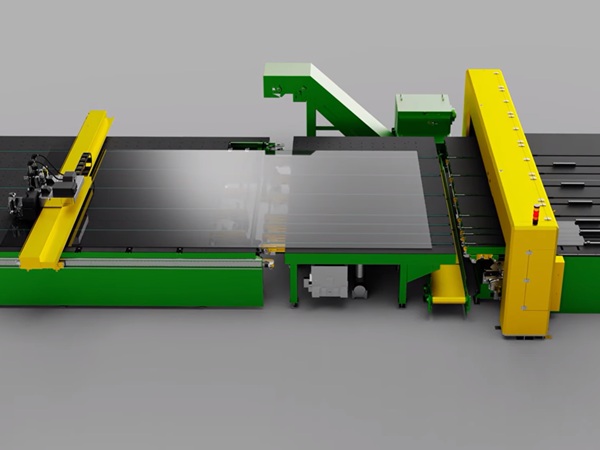

Glaston has received orders from Fuyao Group in China. The orders include several Glaston CHAMP EVO automotive glass pre-processing lines, and are booked in Glaston’s Q3 and Q4 2024 order book. The CHAMP EVO lines will be delivered in the second and third quarters of 2025.

Fuyao Group ranks among the top companies in the global automotive industry and the company continuously develops production automation, intelligent manufacturing and quality. Fuyao’s products are used and highly rated by the world’s leading automobile manufacturers and OEMs.

The customer will use Glaston’s CHAMP EVO pre-processing lines for cutting and grinding automotive windshields and sidelites. Also, some of the lines for sidelite production include the drilling function. In addition to grinding quality, high efficiency and precision in cutting, short changeover times between glass batches and a high degree of repetition accuracy were capabilities the customer was looking for.

The ordered Glaston pre-processing lines will add new production capacity for Fuayo Group’s factory sites in the Anhui and Fujian provinces. Fuyao Group’s new plant in Anhui is considered to be one of the largest automotive safety glass processing plants in the world.

“We have worked a long time with Fuyao and are happy that our products support their position as a high-quality automotive glass processor. These orders also demonstrate that providing locally produced machines close to customers in the growing mobility market is well received, and will support our strategic growth plans in the mobility market,” says José Yepes, SVP Mobility, Display & Solar at Glaston Corporation.

600450

600450

Add new comment