Date: 1 October 2024

The construction industry’s tightening regulations for energy efficiency demands more from the architectural segment. When older double insulating glass unit (IGU) performance is no longer enough to meet energy efficiency requirements, triple and quadruple IGUs are needed. Triple IGUs are a viable solution for new buildings, but often cannot be used to replace double IGUs in old buildings because the width of the triple IGU doesn’t fit into the existing window frame.

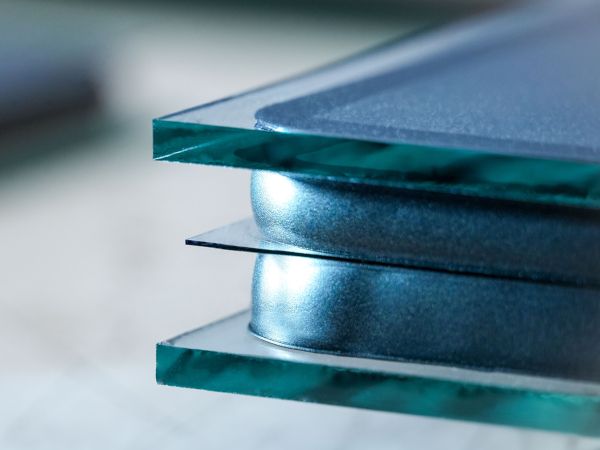

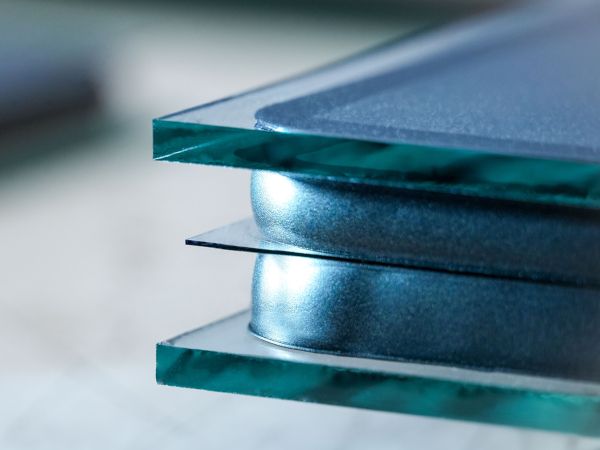

With Glaston’s TPS® technology, customers can produce triple IGUs using thin glass. The use of traditional soda lime glass as the middle pane in a triple IGU can be replaced with glass available in 0.5 mm thickness, like Corning® ATG™ Glass. Corning ATG Glass was developed by Corning Incorporated, one of the world’s leading innovators in materials science. This glass is specifically designed for architectural applications and can be utilized in buildings where thin, lightweight, thermal-efficient, and damage-resistant features are required.

The final thin glass triple insulating glass product is similar to a standard double IGU in overall thickness but has the performance of a standard triple IGU with less weight and frame support needed. This makes thin triple IGUs featuring ATG Glass well-suited for retrofitting existing double IGUs. In addition to increased light transmission and energy efficiency, thinner glass also uses less material.

“By bringing together our ultra-thin Corning ATG Glass and Glaston’s extensive experience in glass processing technology, our customers now have a turnkey solution for producing thin triple and quadruple IGUs,” says Ron Verkleeren, Senior Vice President, Corning Emerging Innovations Group. “Corning's commitment to bringing cutting edge innovations to the architectural segment through its collaboration with Glaston provides a great opportunity for us to broaden our current and future product offerings.”

“Sustainability is high on our strategic agenda, and it is great that our technology is enabling further improvements in the energy efficiency of buildings, old and new. Thin triple IGUs, in a variety of shapes and sizes, have all the benefits of high-performance glazing: energy efficiency with high insulation, more light, slimmer and lighter packaging, less weight and material needed. Our development of the TPS® process for thin glass follows Glaston’s long history of providing “first-of-its-kind” market solutions and has already been well received by customers,” says Sasu Koivumäki, Chief Sales Officer at Glaston Corporation.

600450

600450

Add new comment