Date: 16 September 2005

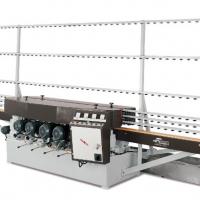

CHIARA MTP operates LOW-E glass without contact with the coated surface.

The important novelty that allows the simultaneous grinding of the four glass sides, allows the machine to be the only edger that automatically corrects the dimensional imperfections of the cutting and accept random sizes and thickness.

The machine requires less space than a complete double-edging line and is substantially faster.

CHIARA MTP can be the heart of a production cell: in line with Francesca drilling machines, it can directly feed a tempering furnace.

FRANCESCA FC 32M 3200 Mill: the machine performs drilling, countersinking and milling operation on glass panels with max dimensions 3210x6000 or two glass panels simultaneously, without intermediate handling.

The newly patented transport devices based on dynamic vacuum system, grants the glass to be perfectly hold by its lower surface only, allowing operations on any kind of LOW-E glass. This system also reduces the normal production cycle time of 50%!

Francesca FC 3200 can be connected with the Forvet Chiara grinding/polishing machine or any existing double-edger, doubling the output.

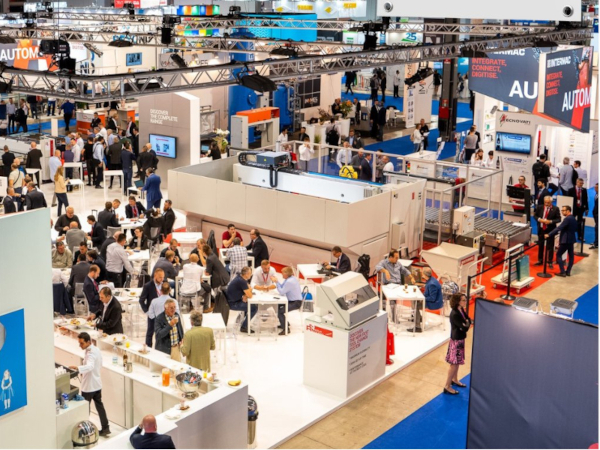

COMPLETE PRODUCTION LINES for drilling, countersinking, milling and grinding operations.

The line composed by CHIARA and FRANCESCA machines offers to the user a unique power of production combined with an unrepeatable flexibility of performance.

The line Chiara & Francesca is the combination of two diverse processes that can operate different glass thickness and different glass sizes in full automatic operations, without manual adjustments. This advantage can be found only within the Forvet production.

The line can grind or polish flat and arris glass edges, can drill, countersink and mill straight glass or shapes.

The Line Automation Control supervises all the line functions, synchronises the speed of the conveyors and controls the link between the Forvet equipments and the other equipments such as the washing machines.

The line can be connected to the production control office so that all the working programs can be downloaded from the office and sent to the workshop directly.

Add new comment