Date: 8 March 2011

The glass envelope encasing the bridge consists of curved panels of laminated glass made with DuPont™ SentryGlas® interlayer, specified by the structural engineers Schlaich Bergermann und Partner and the specialist contractor Bellapart on the basis of its decreased deflection and superior post breakage behaviour as compared to laminates made with PVB. Moreover, the proximity of the research facility to the sea meant that the excellent weathering and durability performance of laminates made with SentryGlas® were further criteria for their selection..jpg)

Bellapart

The two buildings at the ‘Champalimaud Centre for the Unknown’ are connected by a lightweight steel and glass bridge encased by curved panels of laminated glass made with DuPont™ SentryGlas® interlayer. The stiff and strong high-performance interlayer from DuPont was specified for the installation on the basis of its decreased deflection and superior post breakage behaviour as compared to laminates made with PVB.

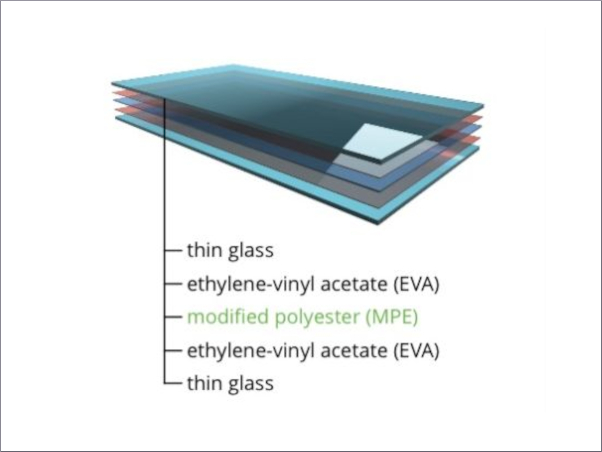

The ‘Champalimaud Centre for the Unknown’ was designed by Charles Correa Associates of Mumbai, India, and comprises two buildings set in a large public area that accommodate treatment units, research laboratories, an auditorium and exhibition area as well as the offices of the Champalimaud Foundation itself. The buildings are connected by a 21-meter-long steel and glass bridge, implemented by Schlaich Bergermann und Partner of Stuttgart, Germany, Prof. Schneider from TU Darmstadt, Germany and Bellapart of Olot, Spain. The curved glass envelope for the bridge consists of several laminated glass panels, each typically measuring 1950x1320mm and produced by the Spanish laminator Cricursa using a comparatively lightweight construction of 8 mm tempered HST glass + 2.28 mm SentryGlas® interlayer + 8mm tempered HST glass. The panels are held in place by four custom-designed clamp plates from Bellapart, located at the glass vertices, whilst vertical steel rings positioned at every two meters along the envelope are used for its support.

Calculations by Schlaich Bergermann und Partner, carried out in partnership with Prof. Schneider of the TU Darmstadt, confirmed that in order to achieve a comparable rate of deflection in similarly-sized laminated glass panels using a PVB interlayer, glass thickness would need to be increased from 8+8 mm to 12+12 mm. Not only would this add significant weight to the installation, requiring a more substantial supporting structure, but it would also become difficult to achieve the required radius for the curved panels..jpg)

Bellapart

The curved glass envelope for the bridge consists of several laminated glass panels, each typically measuring 1950x1320mm, which are held in place by four custom-designed clamp plates located at the glass vertices. Vertical steel rings positioned at every two meters along the envelope are used for its support.

Familiar with SentryGlas® from previous projects, Bellapart repeated the glass load calculations for a laminated glass panel made with the DuPont interlayer to ensure compliance with safety requirements, as Carles Teixidor, industrial engineer at Bellapart explains: “Our own calculations verified the low rate of deflection of the laminated glass panels with SentryGlas®, below L/100 in the 8mm + 8mm construction, which is achieved despite exposure to quite high wind loads resulting from its geometry as well as its proximity to the sea. Moreover, the excellent post-breakage performance of laminated tempered glass with SentryGlas® in the event of failure of non-vertical installations was key: thanks to the high stiffness and limited creep of the interlayer, there is an extended period between the potential failure of the two glass components and the detachment of the panel from its fixings, enabling more time for its repair or replacement and limiting the potential for danger to passers-by.” With the bridge being installed just a few metres from the sea, the superior edge stability of SentryGlas® also came to the fore on the glass panels with open edges at either end of the bridge. “There was no weather seal used to protect these panels from the external environment, yet the outstanding edges stability of SentryGlas® will ensure that no appreciable edge delamination and no measurable moisture intrusion occurs,” confirms Carles Teixidor.

The ‘Champalimaud Centre for the Unknown’ is located on a 60,000m2 site in the Belém district of Lisbon, where the Tagus River flows into the Atlantic Ocean. Its location is of particular historical significance, being the place from where Portuguese pioneers set sail to discover the ‘unknown’ in the 15th and 16th centuries. The purpose of the multidisciplinary research centre is to leverage this historical heritage by creating a link between the discoveries of yesteryear and new scientific research in the fields of neurosciences and oncology. It was officially inaugurated on the 5th October 2010 by the President of the Republic of Portugal.

DuPont Glass Laminating Solutions provides materials, services and innovations to makers and specifiers of laminated glass. It helps create a better world by improving home protection and automotive safety, and enabling design of stronger, more energy-efficient buildings that let in more natural light.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 90 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval, DuPont™ and SentryGlas® are registered trademarks or trademarks of E. I. du Pont de Nemours and Company or its affiliates.

Photo (a): Bellapart

The two buildings at the ‘Champalimaud Centre for the Unknown’ are connected by a lightweight steel and glass bridge encased by curved panels of laminated glass made with DuPont™ SentryGlas® interlayer. The stiff and strong high-performance interlayer from DuPont was specified for the installation on the basis of its decreased deflection and superior post breakage behaviour as compared to laminates made with PVB.

Photo (b): Bellapart

The curved glass envelope for the bridge consists of several laminated glass panels, each typically measuring 1950x1320mm, which are held in place by four custom-designed clamp plates located at the glass vertices. Vertical steel rings positioned at every two meters along the envelope are used for its support.

Add new comment