Date: 1 July 2019

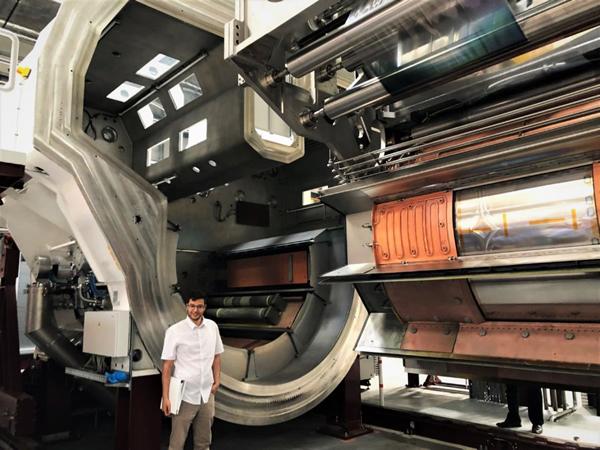

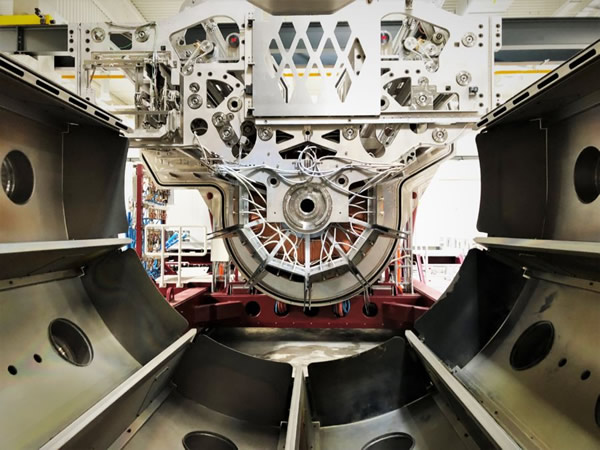

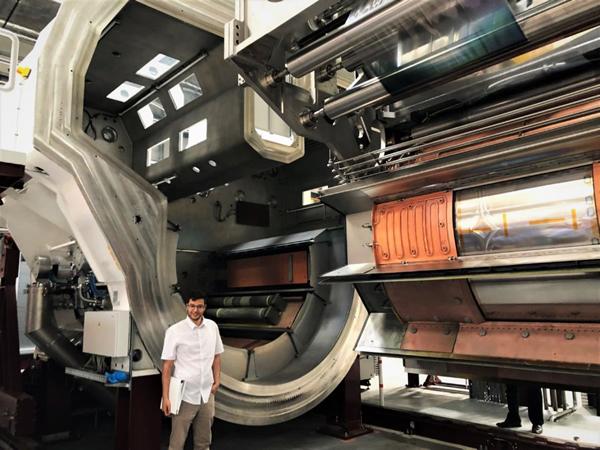

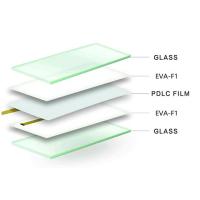

A major process in the production of ChromoGenics’ dynamic product is sputtering. It is made in special machines in a roll to roll process where a plastic film is coated with nano-thin electrochromic material. This high-tech and continuous process gives ChromoGenics a great competitive advantage over other companies that exist in the world, as it offers, among other things, the possibility of large cost advantages compared to the batch production that is otherwise used.

ChromoGenics has recently signed an agreement with a German company to acquire four such machines. Two machines are full-size production machines of about 130 tonnes, sputtering rolls up to 2000m in 1600mm width, the other two being R&D machines that sputter 500m in 200mm width.

An LOI is signed with Uppsala University in order to place one development machine at the Ångström Laboratory, where ChromoGenics intends to develop the material of the future together with the University and secure the availability of competence, the other will be run in ChromoGenics’ new factory and used for development of our processes.

The factory, which is unique in its kind, for northern Europe is estimated to have about 10 employees and the capacity will be over 500 000 square meters per year of electrochromic foil when the factory is fully operational.

“It is a milestone in our history to acquire these machines. Much of our know-how and many of our patents are related to this process and now having this process in the house will be crucial for our future. We shorten lead times, get direct control of the quality and get great opportunities to step into the huge cost leadership that this process enables. We will have a capacity that will last for many years to come and this gives us the opportunity to become the world leader in terms of dynamic glass”, says COO Micael Hamberg.

600450

600450

Add new comment