Date: 5 February 2018

Having access to laser-based processes is something most people within the industry agree, but it requires the technology itself to fit a facilities process flow, materials handling methodologies and ultimately add value to their products.

Freedom To Choose The Materials You Use. As it stands today, being competitive, is an absolute necessity; that doesn’t come from accessing technology that limits you to one material supplier.

The industry wants and deserves choice; this means they need to be able to access thin glass laser cutting technology without having to be limited to one thin glass materials manufacturer.

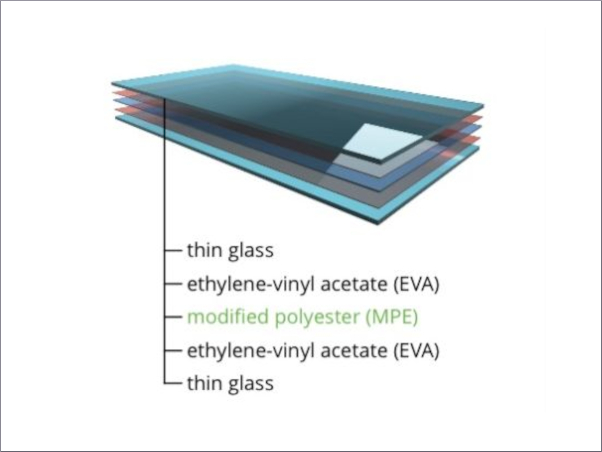

Ultimately working with a laser system group, as a technology partner, that works with its client to provide a complete solution for thin glass laser cutting and fabrication is optimum. Thin Glass

Opportunity: Converging Technologies. The outlook is exciting for laser cutting thin glass materials. New processes for laminating matched with complex geometries offer opportunities for innovation and product life-cycle extensions for existing products.

With the latest and greatest display techniques adapted to automotive applications, glass fabricators in the U.S. might be able to realize a surge in sales if they acquire flexible tooling for processing.

This flexibility also extends to being flexible in the thin glass materials they select; trading off name brands for high value-added niche markets and newer material sources for higher volume commercial and automotive applications.

The day of one source for precision thin glass material is in the past; more options are available at prices that will usher in a new age of innovation for those who embrace the technology. BOLD Products

600450

600450

Add new comment