Date: 9 February 2016

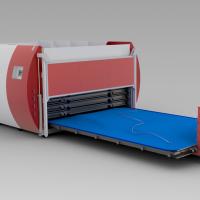

Our latest project is the development of a new trimming line for the removal of PVB foil after the autoclave process.In modern vehicles the glass edge of lites is mostly visible.This requires a precise cutting of foil. Because of this, the existing process (with one knife) is no longer usable.

BENTELER has developed an innovative solution where the knife has been replaced by a grinding belt.

The grinding belt prevents a fraying of the foil. A high-quality and perfect grinding result is achieved.

An additional advantage is the uninterruptible processing process. Due to the use of two trimming heads, the change of the grinding belt is possible during operation. Hereby the productivity can be increased and the production cost can be reduced.

BENTELER offers due to its focus on leading technologies on the one hand and cost reductions on the other hand, the appropriate response to the current market needs.

600450

600450

Add new comment