Others also read

| Dynamic mechanical analysis (DMA) experiments were carried out on three different Saflex® interlayers from commercial production, all at a nominal thickness of 0.76 mm.

| The study describes the results of the principal applicability of fiber optic strain sensors to evaluate the structural behaviour of laminated glass and provides the basis to define a model for the material characteristics of viscoelastic interlayers.

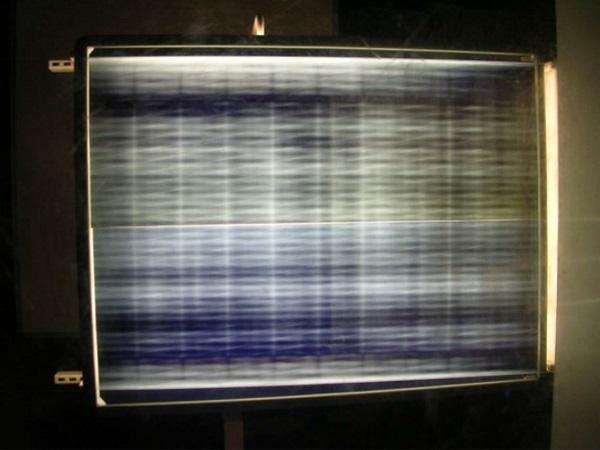

| In today’s architecture the bending of glass plays an important role in achieving free forms in modern façades.

| Glaston is working hard to make tempering furnaces more automated.

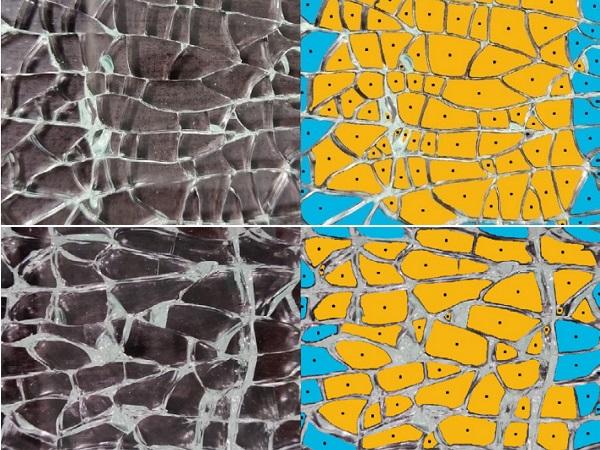

| It is a very known behavior that the glass fragmentation depends on where you break the glass.

| The Surface Compression Stress (SC) data, collected by Stazione Sperimentale del Vetro, were analysed to compare the measurements carried out by Scalp-05 (Scattered Light Polariscope) and Laser Gasp (Strainoptics’ GASP® Polarimeter).

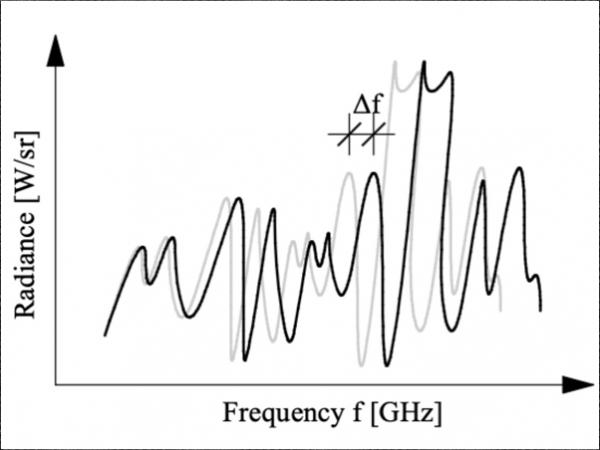

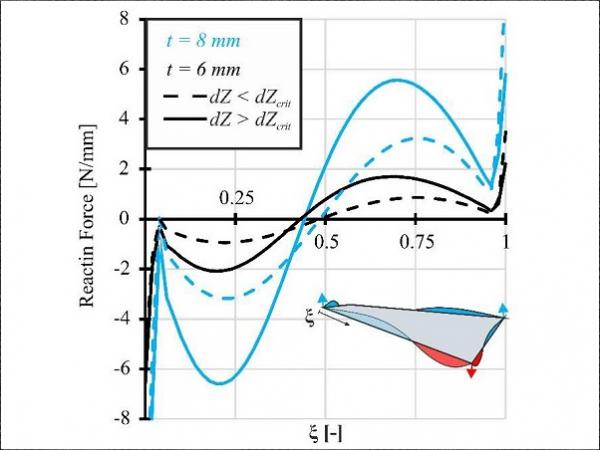

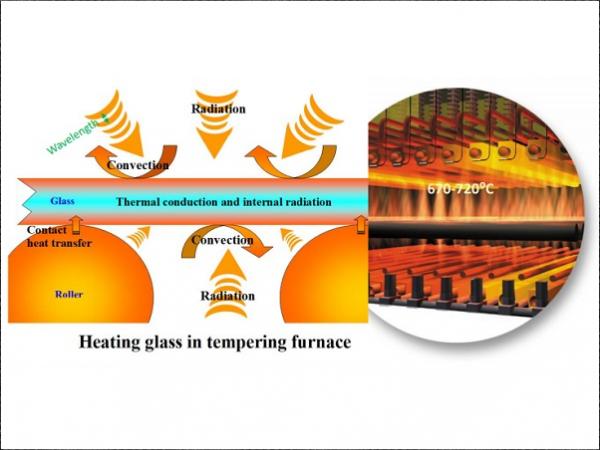

| In this paper, the basics of the heat flux modes are given, a solution method for the glass energy equation is introduced, and some tempering furnaces are theoretically studied to show the portions of the heat transfer phenomena inside furnaces during heating.

| This paper was first presented at GPD 2019 by Louis Moreau from AGNORA, Canada.

| In this article, the prestressing profile of chemically prestressed glass panes is investigated and two different measurement methods for recording surface compressive stress will be presented.

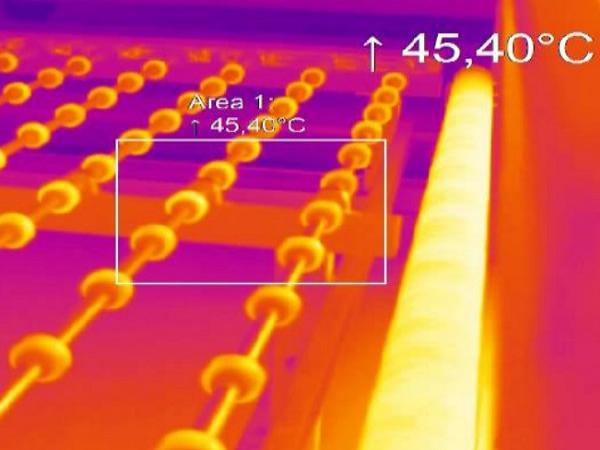

| The Correct Adaptation of IR Thermometers and Cameras to Different Applications

| In this paper local heat transfer of impinging small jets on surface heat transfer and residual stresses is studied.

| The use of laminated safety glass instead of single glass sheets is especially important in order to mitigate the risks of potential post-breakage behaviour and thus for the fixation of glass fragments in case of damage to the glass.

| The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass.

| A couple of years ago all started with the first measurement of anisotropies and edge stress as well as the detection of White Haze and other glass imperfections right after the furnace.

| The author proposes a simple surface quality test using a standard window cleaning scraper and common smartphone or shop microscope.

| This blog post was written based on an interview with M.Sc. (Chem.) Santtu Jolkkonen, Sparklike's Service and Maintenance Manager, who has been working as technical support specialist for Sparklike over a decade.

| Learn about the first step we take in maintaining tempered glass quality standards.

What do power consumption, installed power and installed capacity of a glass tempering furnace mean?

| Power consumption of the glass tempering furnace refers to the amount of electric energy consumed in the process of tempering certain quantity of glass. The measuring unit commonly used is the kilowatt hour (KWh).

| We’ll help you meet the spec with our knowledge of the glass tempering process.

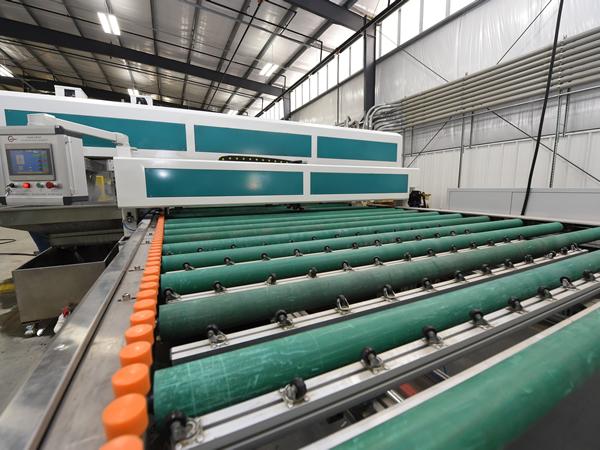

| Keeping impurities away from the glass is imperative in the glass tempering process. These impurities can cause damage resulting in a product that doesn’t live up to aesthetic standards, won’t meet a client specification or is completely unusable.

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

| “Thank you for all the services your company has provided for us. We really appreciate all, the great installation and startup of the RC200™. We are very happy with the outcome of our new furnace.”

| For the past five years, Nile Aluminium & Metals Company, or AluNile, has had very positive experiences with Glaston's first FC500™ tempering furnace sold outside Finland.

| After 10 years of experience with the Glaston HTF 2142 furnace, Paul Buckley, Managing Director of the PJB Glass Group, decided to complement his flat glass production offering by investing in a Glaston RC200™ furnace.

| Sanshiba Shozai of Japan chose to be the first glass processor in the world to invest in Glaston’s latest GlastonInsight™,the intelligent online assistance system, at the same time as it ordered the Glaston RC350™ tempering furnace.

![Tempered Glass Specifications [Video & Transcript] Tempered Glass Specifications [Video & Transcript]](/sites/default/files/styles/6/public/articles/2017/HHH-Tempering.jpg?itok=P7frNEF5)