While these aspects have long been key aspects in the hollow glass industry, the flat glass industry is in a more difficult position.

Whether the material is used as reusable packaging or as a recyclable material, collection systems for hollow glass have a certain tradition in Germany and the recycling rates are high. This saves on raw materials and energy, while also reducing CO2 emissions.

However, this is more difficult for flat glass – flat glass cullet can only be reused to a limited degree and quality demands are high. Flat glass cullet arrives at recycling companies in a variety of forms depending on the application but is rarely just float or cast glass: the cullet can have thermal insulation or sight protection coating attached to it, be printed with ceramic inks, be part of laminated units or wired glass. All of this complicates the preparation process and reduces the number of ways in which the cullet can be reused. Moreover, laminate glasses with specific functions will be used much more often in the future, with the challenges growing as a result.

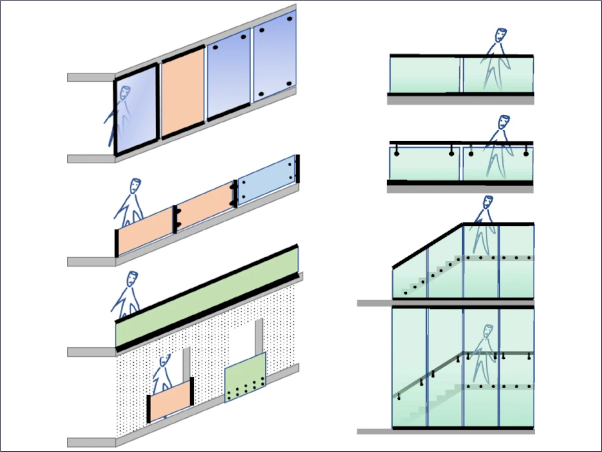

As a general rule, flat glass cullet comes from two areas. Cullet from production is created at the cold end of the manufacturing process, on cutting or prestressing systems, for instance. The processor can almost add this cullet directly to the flat glass producer again, as it is very similar to the original flat glass. Once coatings, lamination or other functions have been applied, this is no longer as simple.

It becomes more difficult still with building elements, the second area from which flat glass cullet typically originates. Flat glass from the automotive industry, façade glass or window elements are placing increasingly high demands on recycling companies. Laminate glasses contain a huge variety of materials, ranging from PVB foils and liquid crystal layers all the way up to metals.

At the same time, there are very few systems that allow these glass products to be collected and prepared in a traceable manner, either on a national or a European level. According to the latest figures, cullet makes up 26% of the raw materials used to manufacture flat glass in Europe (1). It is currently estimated that technical, infrastructural and economic framework conditions limit the existing potential to a maximum of 37% cullet use (1).

Example: the Netherlands

The Netherlands has a nationwide collection system. Following an initiative to set up a recycling system in 2000, Vlakglas Recycling Nederland was founded in 2002. The organisation collects all types of flat glass – including wire glass and laminate glasses – and processes them to create a recycled material. The foundation for this is a network of collection points at glass manufacturers or processors, in waste management centres and in on-site container collections used by demolition firms.

The system is financed through a mandatory recycling fee calculated on the basis of the area of the manufactured or imported glass. In 2019, Vlakglas Recycling Nederland collected and prepared some 80,000 tonnes of flat glass. Unfortunately, at just 7.5% in 2018, the share of glass that was fed back to the flat glass manufacturing process remains small (2). As in other countries, the majority went to the container glass industry and glass wool production. In the long term, however, the organisation aims to raise the share of waste flat glass fed back to flat glass production to 20%.

Material flows in Europe unknown

Unfortunately, very few European countries have traceable material flows of flat glass. During a study by ift Rosenheim (3), information was gathered from flat glass recyclers, float glass factories, flat glass finishers, insulation glass manufacturers and the windows/façades industry in Germany. Unfortunately, as many stakeholders were unwilling or unable to provide details, the data is mostly based on information provided by recycling companies. Despite the great efforts of the authors, the information is not conclusive and is contradictory in parts.

Further investigations in other European countries produce a fuller picture. Although the ARUP study on architectural glass in the United Kingdom (4) showed that a number of window manufacturers were willing to improve the recycling process within the scope of corporate social responsibility, here, too, it became evident that significant improvement cannot be expected without legal requirements. The French project REVALO is comparable to this (5).

However, it is necessary to gain a knowledge of the collection infrastructures of the countries in order to understand material flows. Neither the infrastructure nor the legal requirements are currently sufficient to record the flows of recyclable materials and process laminate glass and building elements in such a way that a large proportion can be fed back into the production of higher-quality products.

The basic legal provisions in this area are the Waste Framework Directive 2008/98/EC and the Landfill Directive 1999/31/EC. Discussions held by the Glass Technology Forum with Glass for Europe and the European Federation of Glass Recyclers (FERVER) revealed that the organisations share the same goals to a great extent.

Sustainability begins with development

As it is still highly difficult to quantify the actual material flows, more specific target values need to be defined for flat glass, for example in demolition and renovation projects. This will then allow the actual technical effort and financial outlay to be quantified more accurately. High costs usually prevent recycling companies from processing building elements containing glass. Separating the material from other construction waste is an early hurdle, while dismantling the building elements poses an even greater challenge.

The amount of work and personnel expenditure for separating the building elements, the space requirements and the transport costs are just some of the factors that need to be taken into account. Unfortunately, in many countries it is still possible to dispose of glass waste at a landfill site together with other materials as an inert material. In doing so, an important raw material is lost. In the future, laminate glass will contain much more material that is to be recovered.

In order to do this in a cost-effective manner in the future, it is necessary to enhance or develop completely new separation technologies – a task that the mechanical engineering and research must overcome together. An end-of-life strategy is absolutely necessary before a manufacturer launches a new product on the market. Sustainability begins with product development.

As such, there is much work to be done. The currently valid Waste Framework Directive points the way forward – even today, glass can surely make a significant contribution to the circular economy and sustainability. But its potential here is far from exhausted. For instance, construction glass and windscreens can show which steps are possible with quota schemes and “design for recycling”. The current revision of the End-of-Life Vehicles Directive would be a first step towards setting concrete requirements here.

References

- Europe, Glass For. Flat glass in climate-neutral Europe. Brüssel : Glass For Europe, 2020.

- https://www.vlakglasrecycling.nl/index.php?page=home-en. https://www.vlakglasrecycling.nl/index.php?page=home-en. [Online] [Cited: 10 15, 2020.]

- Ansgar Rose, Norbert Sack, Klemens Nothacker, Andrea Gassman. Recycling von Flachglas im Bauwesen - Analyse des Ist-Zustandes und Ableitung von Handlungsempfehlungen. ift Rosenheim. Stuttgart : Fraunhofer IRB Verlag, 2020. ISBN 978-3-7388-0459-1.

- DeBrincat, Graeme and Babic, Eva. Re-thinking the life-cycle of architectural glass. Glasgow : ARUP, 2018. Viability study & value report.

- Hestin, Mathieu, de Veron, Sarah and Burgos, Stephanie. Economic study on recycling of building glass in Europe. s.l. : Deloitte Sustainability, 2016.

Important links:

glass.vdma.org

If you have any questions, Gesine Bergmann from the Glass Technology Forum (+49 69 6603 1259 or gesine.bergmann@vdma.org) will be happy to assist.

VDMA represents around 3300 German and European companies in the mechanical and plant engineering industry. This innovative industry is export-oriented and predominantly made up of SMEs, employing around four million people in Europe, including more than a million in Germany alone.