Date: 2 May 2017

Turning unique creative ideas into a reality used to be expensive and time-consuming. Today it’s simple and costeffective.

And it’s all thanks to an intelligent manufacturing process developed as part of the ‘SmartFlex Solarfacades’ EU project. The production line uses technologies proved by automotive and glass industry since many years.

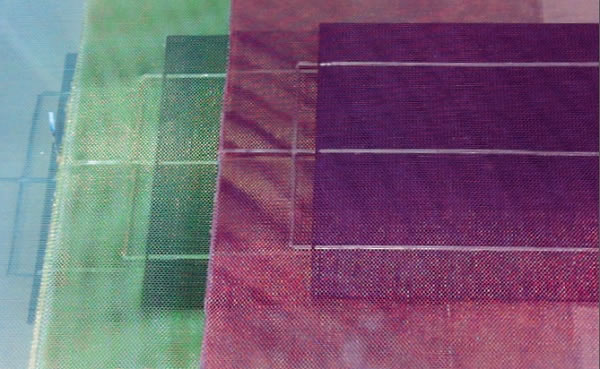

SOLAR MODULES IN DIFFERENT SHAPES AND COLORS

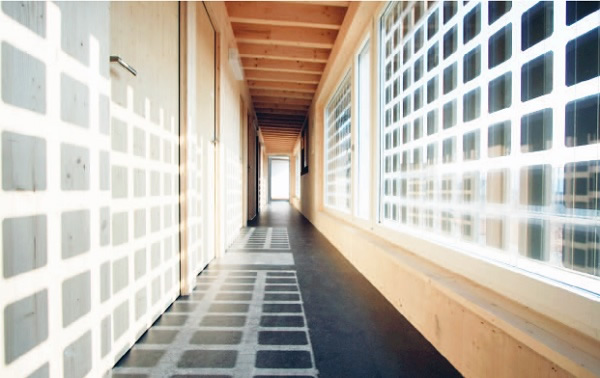

Facades can now be designed to include photovoltaic modules in all conceivable colors and a wide variety of shapes.

What‘s more, both semi-transparent solar elements and modules with printed images are possible. The production line built during the project is also able to manufacture large modules measuring up to 1.7 meters x 3.5 meters on an industrial scale.

PLANNING SOFTWARE CONNECTED TO THE FACTORY

The intuitive SmartFlex software provides architects with a simple way to plan their facades. After the design stage, the data is sent directly to the production line.

Generating an energy yield up to 345 Watt peak, the glassglass solar modules are extremely powerful and can be as thin as 4,8 millimeters.

Manufactured as plug-and-play devices, they are immediately ready for use and are distinguished by an impressively long lifetime of up to 35 years.

BENEFITS AT A GLANCE

- Comply with statutory energy efficiency guidelines

- Use building facades to generate energy

- Save on electricity costs

- Choose from solar elements in a variety of shapes and colors

- Enjoy simplified planning using the SmartFlex software

- Reduce costs with automated production

ABOUT SMARTFLEX

The large-scale EU project is being funded by the European Union’s Seventh Framework Programme for Research and Innovation. Its aim is to further unlock the potential of building-integrated photovoltaics (BIPV).

Eight project partners from research and industry are contributing to developing the smart technology. The first production line for customized solar facades has been constructed by Mondragon Assembly in a factory belonging to PV manufacturer Via Solis in Vilnius, Lithuania.

Here, a state-of-the-art solar facade with printed images is being produced for project partner Glassbel’s office building.

600450

600450

Add new comment