Date: 19 June 2018

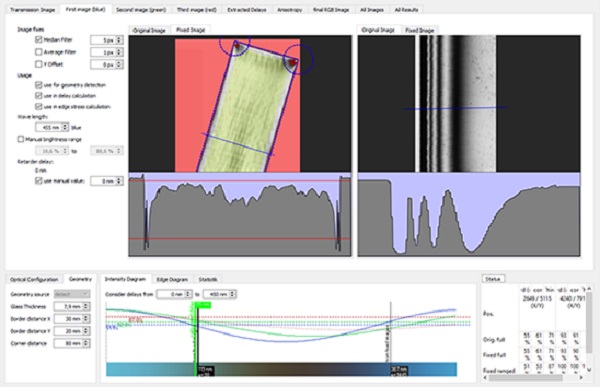

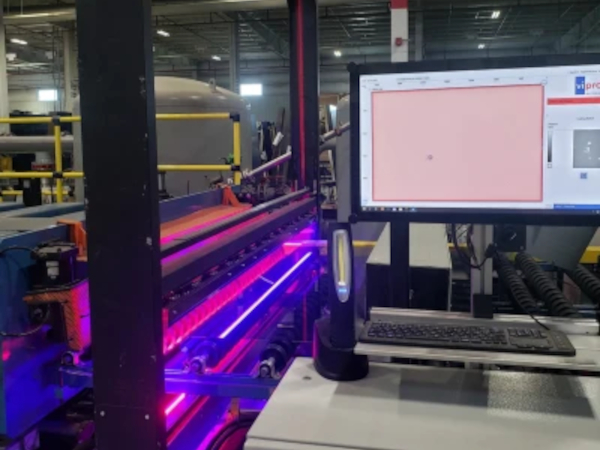

An installation of multiple inspection stations is not required as the LineScanner can perform all of these tests in one. The latest quality check of the LineScanner is the new edge stress detection which is now available as an option.

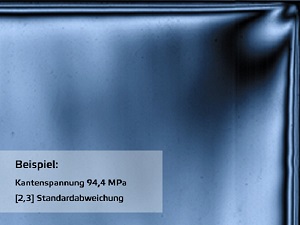

The LineScanner measures the edge stress in megapascals [MPa] every 1.2 mm along every edge of a pane. This ensures that the same degree of heat treatment is always reached as it is required. A distinction in TVG and ESG, as well as the degree of heat treating, can be guaranteed.

A distinction in TVG and ESG as well as the degree of bias ca be guaranteed.

A distinction in TVG and ESG as well as the degree of bias ca be guaranteed.

Based on the edge stress, a direct correlation is made to the surface tension which then directly relates and allows the prediction of the expected fracture pattern!

This development is the result of a joint development project involving UNIGLAS as an industrial partner and the university München and RWTH Aachen universities.

For a fool-proof investment there is only one answer - LINESCANNER from SOFTSOLUTION.

More about edge stress

LineScanner - All-in one functionalities

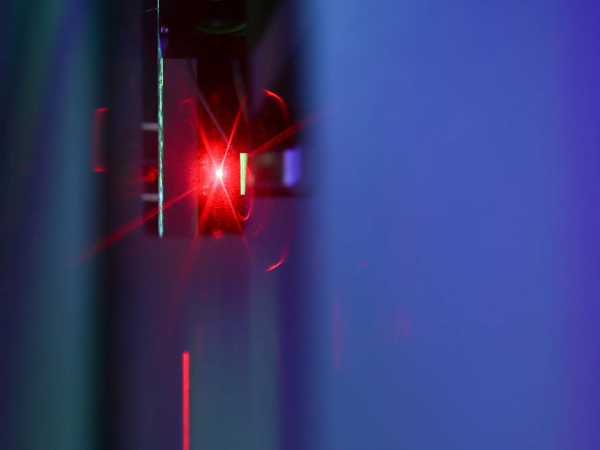

- Anisotropy test (high-precision measurement of the light delay up to 465 nm / pixel optional up to 900 nm/pixel

- Edge stress measurement - based on this conclusion on surface tension and the expected fracture pattern

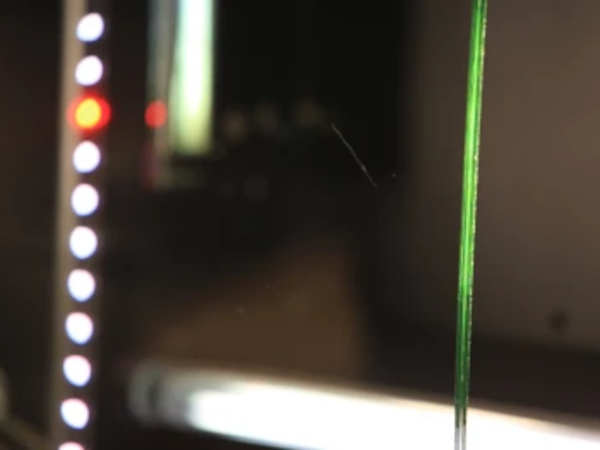

- Optical quality inspection from inclusion, scratches to coating defects

- Dimensional inspection for cutouts and drill hole will check the position and diameter

- Assignment to the correct pane according to batch assignment and thus merging of all quality data for the order item is stored in a database and thus 100% documented

What you need to know about the LineScanner

600450

600450

Add new comment