Date: 11 June 2019

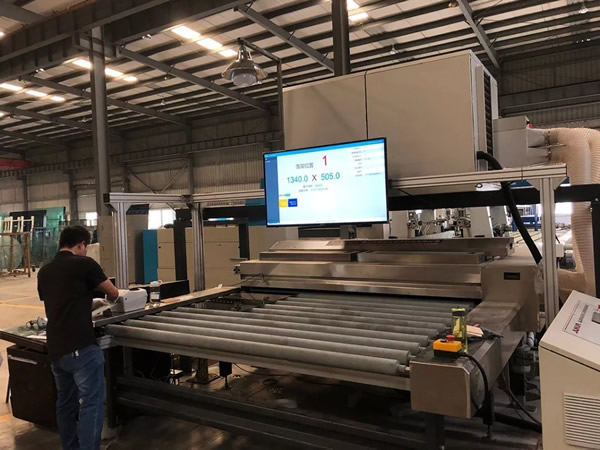

The pretreatment line is equipped with a shuttle glass storage system, a cutting machine, two grinding lines and the gMES system independently developed by NorthGlass. The application of this pretreatment line not only helps the customer greatly improve the production efficiency, effectively reduces the difficulty of management, but also saves the labor costs.

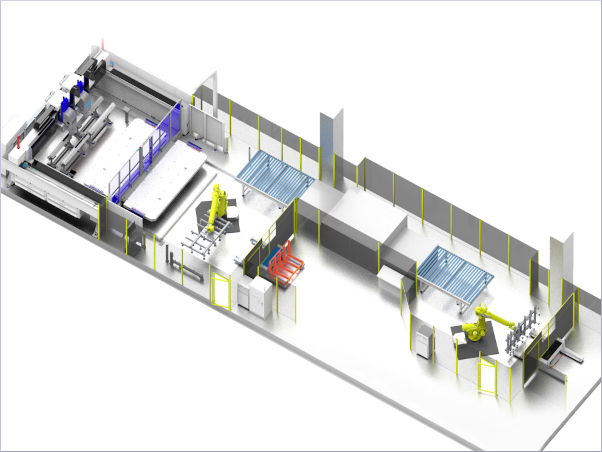

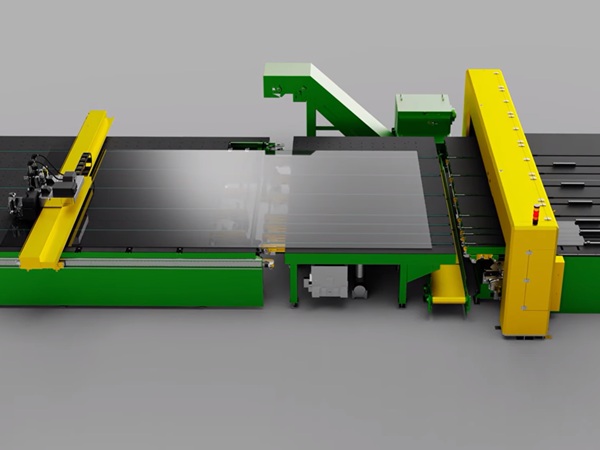

At the beginning of 2019, NorthGlass automation sharding system ordered by a world-renowned enterprise passed the acceptance smoothly. The system is equipped with two sets of NorthGlass glass storage systems, a cutting machine, Y-Axis & X-Axis automatic glass slicing, robot automatic falling frame and the gMES system independently developed by NorthGlass.

Previously, this enterprise used the method of manual glass slicing and sharding, which was prone to occupational injuries and accidental falling-off errors. After the adoption of the NorthGlass automatic glass sharding system, the work injuries, falling-off errors, product defects and other phenomena totally disappeared.

When you start to work every day, you only need to input the processing task list to realize the whole process of unmanned operation. NorthGlass automatic glass sharding line perfectly replaces the original processing mode.

Since the establishment of Shanghai North Glass Automation Technology Co., Ltd., more than 20 glass storage pretreatment line systems have been sold all over the world. While continuously improving its automation technology, NorthGlass has also been highly recognized and praised by customers for the superior service.

In order to achieve the sustainable development of automation, NorthGlass has invested more than 20 million yuan in 18 years. NorthGlass will continue to increase research and development efforts to continuously improve the automated products.

We believe that with the understanding and accumulation of deep processing glass and equipment for over 20 years, as well as the strong advantages of R&D, manufacturing and brand, NorthGlass will join hands with more glass processing enterprises to jointly build an automation factory in the glass processing industry.

600450

600450

Add new comment