Date: 20 December 2006

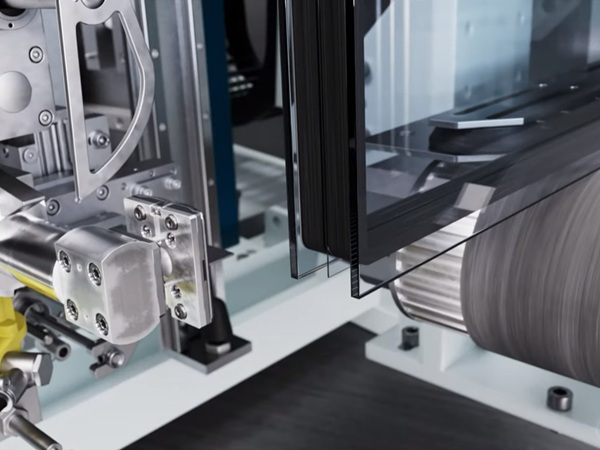

Hot Melt Technologies introduced the Benchmark 615 Hot Melt system that can be used with high-viscosity butyls, sealants and mastics for insulating glass window manufacturing, fabrication of door lites and solar panels, and sealing of metal roof systems.

Features include a 2-gallon, 7" diameter melt tank that accepts chunk materials, 1-pound-per-minute gunning rate, 4 to 8 pounds per-hour melt rate, high-output pump for uniform, pulse-free material delivery, and adjustable flow control for smooth, bubble-free material lay-down. The system comes with an 8-foot heated hose and a lightweight, trigger-activated handgun.

Read the entire news on the source link below.

Nestor.minsk.by

2006-12-20T12:00:00

New Hot-Melt System For Glass Window Manufacturing

glassonweb.com

Add new comment