Date: 11 December 2023

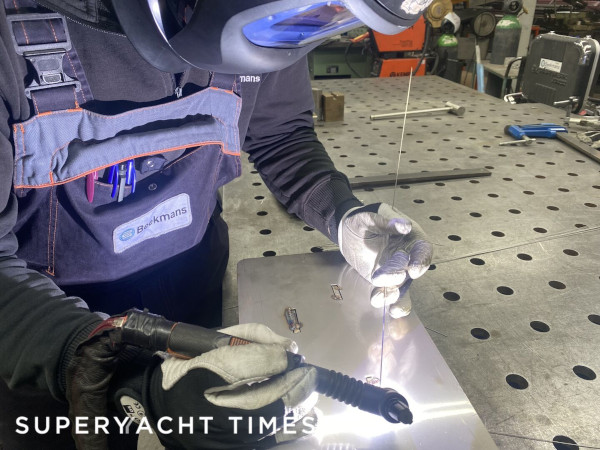

Beginning with the evolution of floor to ceiling windows in the main saloon, and now encompassing the very structure of yachts themselves, glass is one of the most prevalent materials used within superyacht exteriors. While this advent of glass comes with its challenges, one of the companies that has become an expert in its field is the Dutch production and engineering firm Beekmans.

Responsible for the glass balustrades and railings on some of the most recognisable contemporary yachts, Beekmans is grounded in the goal to up the standards of safety and durability for its products. We sat down with the team to find out more.

From Steel to Glass

Originally specialising in stainless steel manufacturing, Beekmans has been a household name in the maritime sector and was the first company in the Netherlands to carry out a complete package deal for stainless steel installations on a yacht. But why did the company transition into the glass sector in the first place?

Prior to introducing the glass manufacturing process into its own facility, Beekmans worked alongside a number of partners for the glass segments of their balustrades and railings, producing design files to be sent to the manufacturers. However, the team consistently found that the glass was below the expected standard in terms of durability and strength and that challenges associated with it often lead to delays in the finalisation of the project.

As a result, Beekmans made the decision to bring the production of glass for its products in-house, and to introduce rigorous testing for the entire manufacturing process to ensure that its products were built to the highest standard possible.

“Outsourcing glass can become a lengthy and protracted process, leading to increased lead times,” explains Teun Beekmans, Refit and After Sales Manager. “Now that the production process is in house, we are able to fast track production and deliver the product in as little as a few weeks if necessary. It also enables us to ensure the quality of the glass at every manufacturing stage, and because we have an intimate knowledge of how glass interacts with stainless steel, we are able to navigate any potential challenges before they arise.”

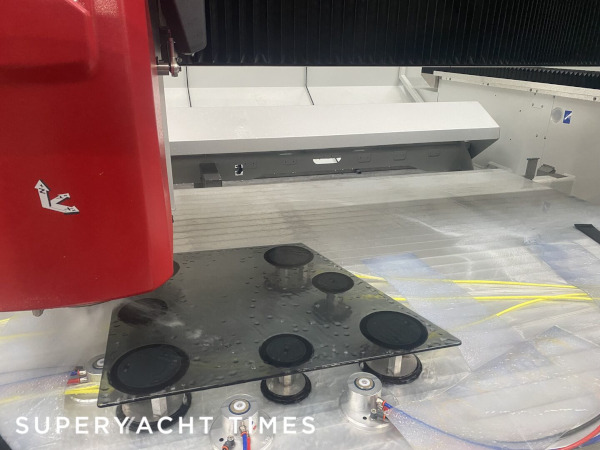

To further expand its manufacturing abilities, five years ago, Beekmans acquired a CNC and milling company, expanding its own facilities with a new laser cutting machine and putting the entire construction process under one roof. Based in Den Bosch, the facility now covers a 9,000 square-metre plot, with 3,000 square-metres dedicated to production, of which 1,000 square-metres is dedicated to glass and over 30 people in the team.

Testing the limits

As one of the main motivators for Beekmans to introduce glass production in-house being the low quality of glass available in the sector, testing its products has always been at the forefront of the company’s mind. Superyachts are regularly put under strain, with heavy loads, rough seas and potential impact all adding to the possibility of glass balustrades breaking.

Over the years the company has introduced new standards of testing for its maritime grade glass and all of its glass meets the stringent standards of class approval. Today class societies are increasing the specification demands for glass railings, leading to challenges within the sector as companies fall below the standard of regulations, leading to unclassified areas onboard yachts. With their own engineering department, chemical toughening bath, cnc glass production equipment and test facility, Beekmans has been at the forefront of glass testing and is able to assist its clients with strength calculations for class submittal.

With the focus on the high demands of yacht building, their in-house production and precise control on that production process, Beekmans acquired type approvals on various glass thicknesses and railing setups. With these type approvals and in depth knowledge of glass and stainless steel, Beekmans is serving the yacht industry at its best.

To find out more about Beekmans, its products and services, reach out to the team now:

Email: info@beekmans-rvs.com

Phone: +31 73 613 20 30

600450

600450

Add new comment