Date: 30 October 2024

On the one hand, the additional types must find a systematic place in the existing storage space in order to react to customer requirements flexibly, quickly and reliably. On the other hand, the profiles must be stored in such a way that they are directly accessible and available without time-consuming handling.

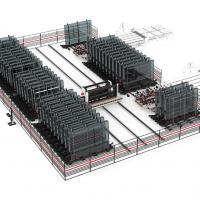

Space savings thanks to mobile shelving systems

With compact storage systems designed especially for long lengths, the HEGLA centre of excellence in Kretzschau offers a range of solutions that provide up to 50 per cent more storage capacity in the same space. To save the maximum amount of space, the system shelves are either mobile on rails or adjacent to each other on rollers. This eliminates the usual operator aisle for a front or side stacker that must be planned in front of every shelf in conventional storage systems. In the solutions from HEGLA, as soon as a pallet needs to be stored or removed, an opening is created in front of the required storage space or the entire shelf is pulled out to the front. The compartment can be accessed directly and without time-consuming re-stacking. “For even greater flexibility, long-length profiles can be pulled out of the storage space from the front, up to maximum working height”, claims Hendrik Boche, head of sales at HEGLA in Kretzschau.

Load capacity up to 15 tonnes

“Together with our customer, we draw up a tailored concept and adapt it to their needs, processes, and the existing storage space”, explains Boche. The possible solutions range from manually or motor-driven transverse storage and shelves that can be pulled out from the front to integrated, fully-automated solutions. Up to 6 pallets can be stored in the cantilever arm shelves mounted on rails in vertical stacks, and then each one can be individually removed via direct access. Additional shelf modules expand the system’s functionality and provide space for single rods and bundles. For over 40 years, the company has implemented numerous storage systems like this in window manufacturing enterprises, as well as the metal processing industry. Depending on customer requirements, the individual shelves have an increased load capacity of up to 15 tonnes and are thus also suitable for storing metal profiles and rods.

“Once the storage system has been integrated into production, it is easier to gain an overview of the available materials. Everything is directly accessible, clearly arranged, and can be traced to the assigned storage compartment and posted in the storage system via scan, for example”, according to Hendrik Boche.

Picking right inside the warehouse

With special accessories, the long-length storage system can be adapted even more closely to the customer’s processes. HEGLA also offers a processing shuttle that enables picking the required profiles and then cutting them right inside the warehouse. The shuttle is moved in front of the shelf and lifted to the required working height by an integrated lifting platform. The required profile can be pulled onto the saw and cut. Depending on the residual length, in order to save resources the profile is returned to storage and is ready for the next orders.

600450

600450

Add new comment