Date: 29 January 2025

Glaston, a global leader in glass processing and innovative energy-efficient glass solutions, and Miru Smart Technologies (“Miru”), a leading smart window technology developer, are working together to accelerate the development and production capabilities of next-generation dynamic electrochromic window (“eWindows”) technologies.

“We are committed to the growth and adoption of innovative new technologies in the glass industry, and are excited to support Miru with our know-how on glass processing processes in their journey to develop electrochromic windows. We see potential in Miru’s novel solution in reaching a more cost-effective, high tolerance and high yield manufacturing of switchable tinted glass than previous approaches,” said Sasu Koivumäki, Glaston’s Chief Sales Officer.

“Glaston has long been at the forefront of glass innovation, and we are excited to be working with them to scale Miru’s next-generation energy-efficient windows,” said Curtis Berlinguette, Chief Executive Officer at Miru. “Miru eWindows offer versatile form factors for a wide range of market segments. With Glaston’s support and expertise in upscaling and technology industrialization, we are looking to advance our go-to-market strategies – delivering on expedited timelines and leveraging Glaston’s process know-how across engineering and manufacturing.”

Miru eWindow technology uses electricity to control the tint level of the glass, automatically adjusting to bring in natural light while controlling heat gain and glare. The eWindows aim to lower air-conditioning loads to help reduce greenhouse gas emissions, while increasing the energy efficiency of buildings by as much as 20%, and the driving range of electric vehicles by up to 10%.

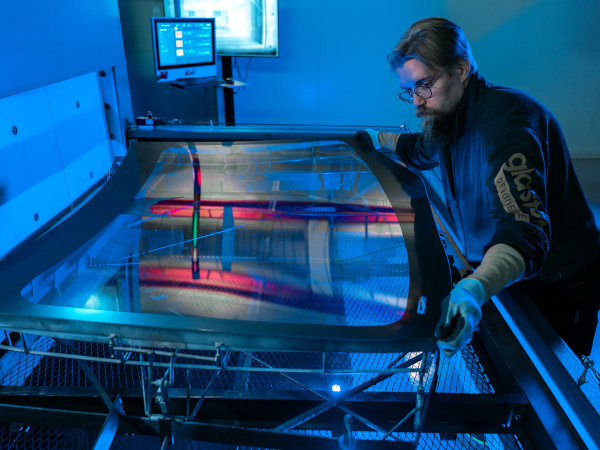

Glaston and Miru are currently working to further develop their respective technologies to enable the expansion of the production capabilities of Miru eWindows. Development and testing of Miru’s solution is done in Glaston’s R&D facility in Tampere, Finland. This will involve combining Miru’s process and materials with Glaston’s glass pre-processing, bending, heat treatment and laminating equipment technologies and know-how.

For Miru, this collaboration will enable greater automation of manufacturing processes, decreasing overall time-to-market while creating new opportunities for customer growth, specifically in the automotive and building industries.

Samples of Miru’s eWindow technology were on display in the Glaston booth at the glasstec 2024 exhibition.

600450

600450

Add new comment