Date: 1 October 2025

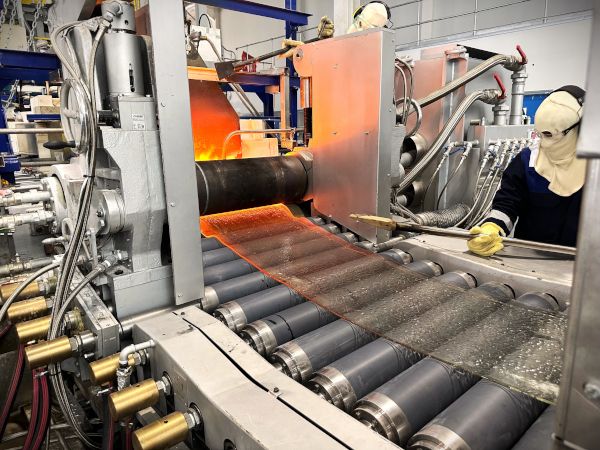

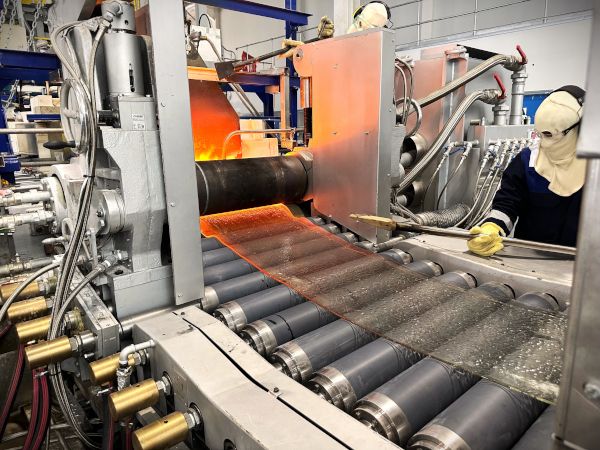

Glass Futures is proud to announce a significant breakthrough in the commissioning of its world-first experimental glass furnace. At the start of this week, the team successfully rolled the first glass from the furnace, marking a pivotal moment in the journey to deliver a transformative R&D asset for the global glass industry.

Glass Futures is a global innovation platform that brings together industry, academia, and government to turn ambition into action. At the heart of its pilot facility is an innovative 30-tonne-per-day oxy-fired pilot furnace, designed to showcase sustainable technologies and approaches.

From pioneering the world’s first multi-fuel hybrid pilot-scale glass furnace, to enabling circular supply chains and smarter manufacturing, Glass Futures delivers real-world solutions at scale.

This achievement follows months of meticulous planning, engineering, and collaboration. The furnace, lit in June of this year, is designed to enable advanced analysis of glass flow and composition.

After overcoming commissioning challenges, including melting glass in an area near the furnace exit where directing heat is more difficult, the team successfully achieved full commissioning of the furnace and began rolling glass through both the rolled plate line and annealing lehr.

“This is a huge step forward,” said Justin Kelly, CEO of Glass Futures. “This milestone brings to life the investment in this national research and innovation asset with globally unique innovation capability. Along with the fantastic team at Glass Futures and our members, we are now fully open and actively collaborating.”

Support from our members who contributed their expertise, played a vital role in this success. Glass Futures will now begin its formal trial programmes, with this milestone paving the way for groundbreaking research and innovation in sustainable glass manufacturing.

Several such pioneering programmes is funded under the UK government’s Industrial Fuel Switching (IFS) initiative from the Department of Energy Security and Net Zero. These programmes will explore alternative energy sources such as waste-derived biofuels, electrical boosting, and hydrogen, aiming to revolutionise high-temperature industrial processes and reduce reliance on fossil fuels.

Aston Fuller, General Manager at Glass Futures said, “Having been part of Glass Futures since the very beginning, seeing the first glass roll from our furnace is a moment I’ll never forget”

Aston added, “It’s the result of years of vision, planning, and relentless hard work from an incredible team. This milestone isn’t just about commissioning a line, it’s about proving that innovation, collaboration, and perseverance can reshape the future of glass manufacturing and beyond.”

“Witnessing the first piece of glass was an incredible moment for the whole team” said Andy Pink, Head of Operations at Glass Futures. “This has been a complex and demanding commissioning process, and I’m immensely proud of the tireless work, resilience, and collaboration that got us here. We’ve overcome real technical challenges, and while there’s still more to do, this milestone proves what’s possible when a team of great people come together with a shared purpose.”

Glass Futures extends its sincere thanks to all of its funders for their invaluable support, including Innovate UK, Liverpool City Region Combined Authority and St Helens Council.

600450

600450

Add new comment