Date: 23 September 2008

As a premiere to the North American glass industry the LSC LINESCANNER (among other new products) will be introduced and demonstrated for the first time during the GlassBuild show in Las Vegas (October 6-8). Following the huge success of this technology in Europe, FeneTech and Softsolution see a huge market potential for this type of equipment in North America.

The LSC LINESCANNER is able to measure and identify glass with a resolution of 400 dpi (0. 0635mm) including the possibility to check drill hole or cut-out positions including shapes by overlapping the original CAD drawing to the scanned result. Furthermore the LSC LINESCANNER is able to detect any type of surface default such as inclusions, scratches, stains, chips, coating defects and others. These tolerances for defect detections can be individually set depending on the allowed tolerances.

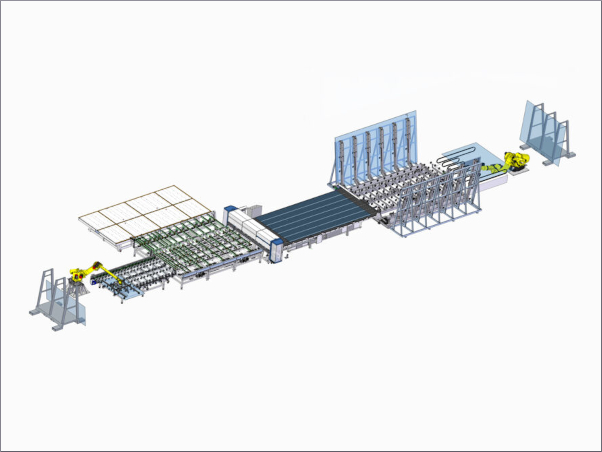

All this is achieved in one single scanning process. The LINESCANNER offers various applications and can be built to any size – it exists as a horizontal or vertical unit. Current applications include installations at tempering furnaces (measure and identify glass and display the result at the furnace exist including the possibility to print labels online (label-less production). Other applications include measuring and quality control at an IG line (vertical scanner).

Technical details: any type of size available, up to 0.5 meters / second speed, evaluation of results occurs within the normal machine cycle time, real illustration of the defect by a high resolution picture, archiving and storing of statistical defect information, little space required, powerful software. The CULLET SCANNER, a sister product of the LSC LINESCANNER allows testing of fragmentation of tempered glass according to various specifications (tempered, heat strengthened, Automotive, shower doors) -

For more information or an individual presentation contact us – www.fenevision.com – Email Horst.Mertes@fenetech.com or give us a call at +1 330 995-2830

Add new comment