Date: 10 July 2020

Motivated by this new trend, architects are creating increasingly dynamic constructions with imposing glass windows.

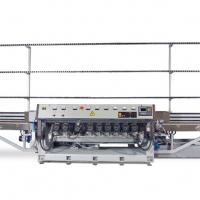

CMS Glass Technology meets this demand with a series of specially designed machines for machining pieces of glass that are more than 6 metres long.

In particular, the vertical profile solution can machine glass panels larger than 7500 mm, guaranteeing a 67% higher productivity compared to horizontal solutions.

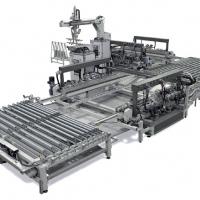

The lack of tooling of the board combined with loading simplicity make the machine an obligatory choice for small batch productions.

A further advantage, thanks to the loading surface of 540 mm, is the ease with which the machine can be integrated into any automated line, creating a continuous work flow.

The possibility of working 30 mm thick glass combined with the full compatibility of low emission glass, does not impose any limit in the choice of material to be used.

TOP BUYER BENEFITS

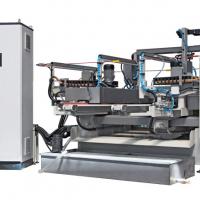

- Endless tools available: 60 tool cone positions and a change time that is 37% faster make Profile a market benchmark.

- Unparalleled shine. With a power of 30 kW in the most powerful spindle in the category, it is possible to shine glass of up to 30 mm thick with an unrivalled quality.

- The glass can be perfectly squared thanks to the suction cups that support 1 ton with a tolerance of +/- 0.15 mm, an unparalleled asset among vertical machines.

SPECIFICATIONS

- Maximum dimensions 7,500 x 3,300

- 30 kW Spindle, 12,000 rpm

- Automatic plate measurement

- Automatic tool brightening

The advantage of drilling without position restrictions, together with the possibility of working thicknesses from 3 to 30 mm, makes it the ideal machine for numerous applications.

Profile is perfectly adapted to working low emission glass thanks to the numerous dimensions available, and is the ideal machine for the building and furnishings industry.

Its high execution speed combined with careful and repetitive precisions fully satisfies even the demands made by the glass industry linked to refrigeration.

600450

600450

Add new comment