Date: 28 February 2013

That was ten years ago.

Since that time, the innovation network consisting of HEGLA engineers, A+W software specialists, and enthusiastic users has never stopped developing and perfecting the residue plate management functions. Users all over the world are saving millions of tons of the precious raw material glass, year in and year out. Not only the business results benefit from this, but also our environment: Saving glass helps to reduce the CO2 emission and saves precious energy reserves. Modern performance glass of which IG producers and other glass processors regularly process about 60 - 100 types, are simply too expensive to be stored by hand "just somewhere", only to be thrown away eventually.

Optimized Machinery Processes

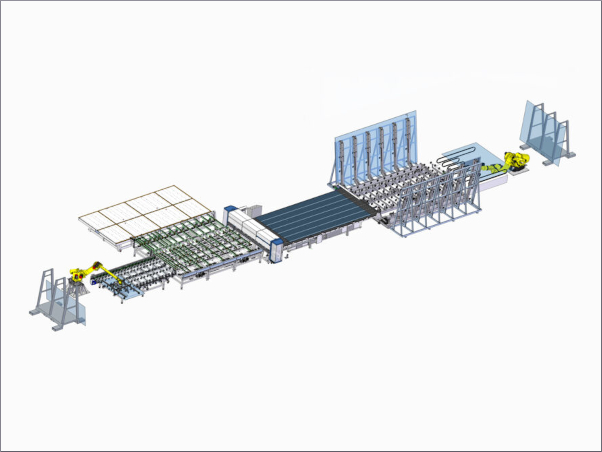

Material savings further profit from the optimization of the cutting process. Thanks to the process- and time-optimized functions of the ReMaster system, unnecessary down times resulting from manual withdrawal of residue plates from the cutting and breakout lines, are avoided. Production jobs can be handled much more flexibly, and the use of machine capacity is improved further. Manual residue plate handling with the risk of damages is completely omitted. Using the ReMaster together with A+W control software can increase the utilization of the cutting lines by up to 10%.

Continous Improvement

Major milestones in the development of the system have been the introduction of the Tandem Remaster with two lift levels for even more flexibility, the Laminated Glass –Remaster, the adaptation of the storer to the existing cutting environment (even for machinery of other suppliers), and the multiple use of slots with software-controlled, random unloading of the residue.

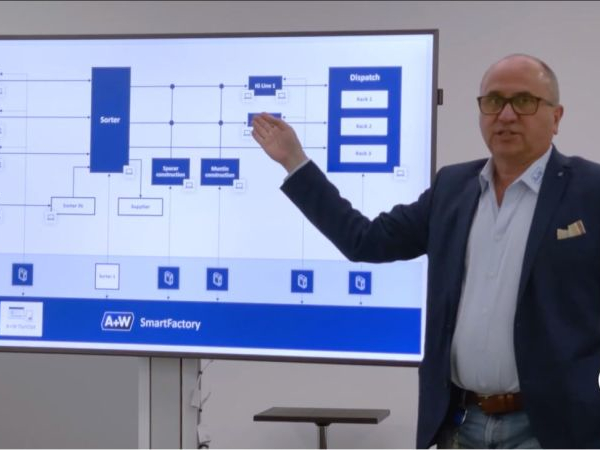

An essential asset has been the development and enhancement of A+W’s premium optimization systems which control the ReMaster: The dynamic optimization DynOpt for instance allows the seamless integration of the residue plate storer in complex, sequence-creating cutting concepts which include the HEGLA SortJet.

Create residue - save material!

Other enhancements are less spectacular but still help to save a lot of material: Creating residue to improve the yield – whoever would come up with such a solution! The A+W team of software developers did: They have integrated the option of specifically enlarging the residue plates to allow them to be stored in the ReMaster which requires a minimum size of the cut plates. If a residue plate is too small to be stored in the ReMaster, it usually goes straight away to the cullet box. If the sub-plate is enlarged by means of intelligent optimization however, it can still be used and thus increases the yield at the end of the day.

Together, HEGLA and A+W have implemented a multitude of successful projects for residue plate management and glass cutting optimization world-wide. Dr. Uwe Schmid, Managing Director of A+W, states: „We would like to congratulate our machinery partner HEGLA to their brilliant success of the ReMaster machines. A+W is proud to have been able to contribute innovative automation and optimization concepts for the optimum use and development of this ingenious concept. My team and I are looking very much forward to future common developments and new, fascinating projects in the field of residue plate management!“

Add new comment