Author: Matthias Fenske | Glaston

Source: www.glastory.net

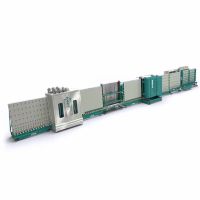

When it comes to sealing insulating glass units, precision and homogeneity of the sealing compound are essential. Glaston’s high-speed sealing robot SPEED’SEALER features a dynamic mixing system to deliver exactly these advantages.

Unlike static solutions, the dynamic mixer uses a motor-driven mixing tool to actively regulate the mixing speed inside the chamber. This ensures a consistently homogeneous mixture of the two-component sealant, regardless of variations in temperature, material batches or start/stop cycles during application.

The system instantly adapts to the required sealing volumes, making high-precision dosing and sealing possible. Thanks to the low system pressure, sealant stress is minimized, ensuring better long-term performance of the IG unit.

The self-cleaning, flow-optimized mixer design prevents clogging and reduces downtime. It is suitable for all state-of-the-art sealant materials, ensuring fast and economical material changes.

The dynamic mixing system not only improves sealing quality but also optimizes efficiency in several key ways:

- High application speed up to 60 meters per minute

- Sealing of up to 200 IG units per hour

- Automatic dosing based on sealing depth detection, ensuring precise material use

In short – With over 1,000 sealing systems installed worldwide, Glaston’s dynamic mixing technology sets the benchmark for sealing quality, process reliability and overall efficiency in insulating glass production.

Comments

This remarkable machine is equipped with a dynamic mixing system that perfectly combines efficiency and precision, ensuring you experience all the advantages you’ve been looking for.