Others also read

| Glaston is working hard to make tempering furnaces more automated.

| That’s an excellent question! It really is true that SentryGlass is more difficult to laminate in many aspects than standard PVB. But if we first think of what SentryGlass has been designed for, it is to give structural strength to the laminate.

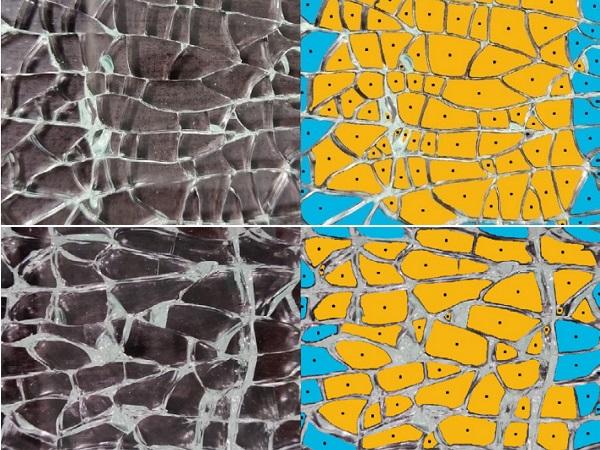

| It is a very known behavior that the glass fragmentation depends on where you break the glass.

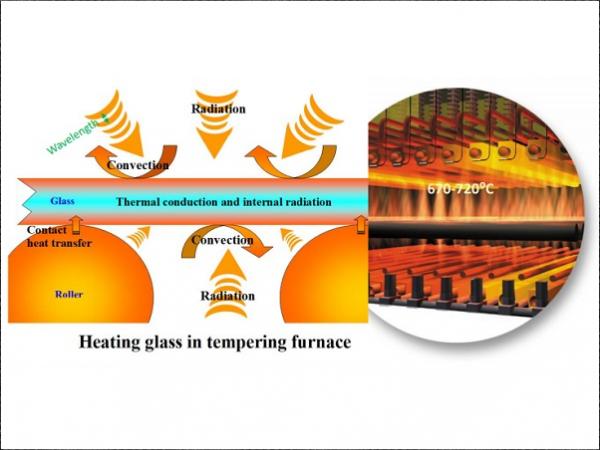

| In this paper, the basics of the heat flux modes are given, a solution method for the glass energy equation is introduced, and some tempering furnaces are theoretically studied to show the portions of the heat transfer phenomena inside furnaces during heating.

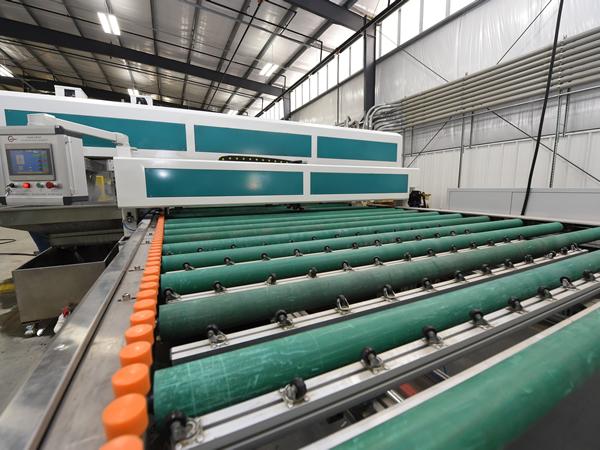

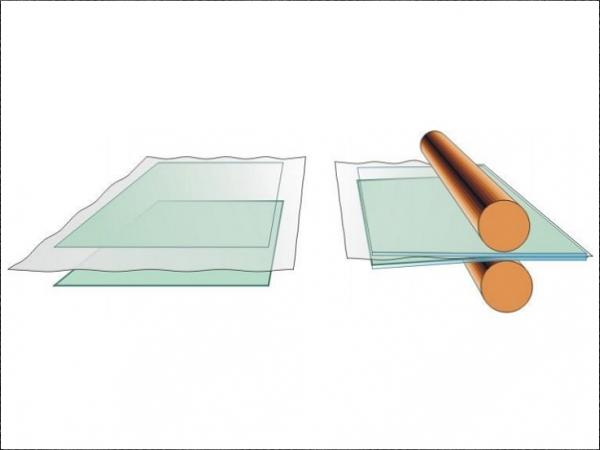

| In a flat glass laminating oven, glass-film sandwiches are located on rotating rollers and conveyed through a heating chamber in a continuous flow.

| Today, when energy efficiency is more important than ever, it’s a good time to speak about insulating glass spacers.

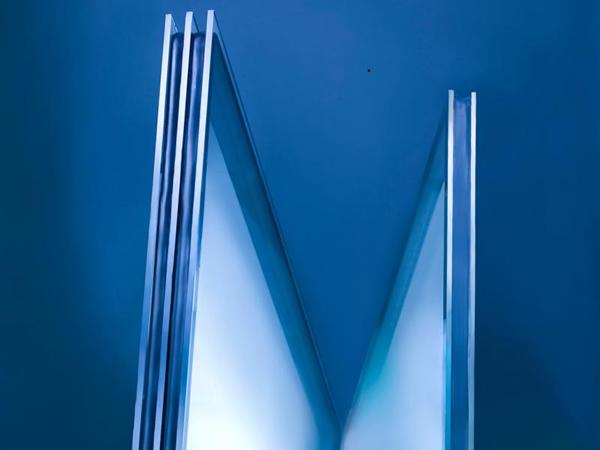

| Insulating glass has been used around the world in applications ranging from family homes to high-scale construction.

| In this paper local heat transfer of impinging small jets on surface heat transfer and residual stresses is studied.

| As a modern society, we’re spending about 90% of our time indoors – at home, in offices or commuting. How is it possible to get access to daylight, when we can’t naturally be outside? By making buildings more transparent.

| As digitalization becomes a strategic discipline in almost all enterprises and industries, the glass processing business is no exception.

| Are you considering adding insulating glass products to your production mix? Or are you thinking of reconfiguring your current equipment to deliver new and better services to your customers?

| The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass.

| The author proposes a simple surface quality test using a standard window cleaning scraper and common smartphone or shop microscope.

| Learn about the first step we take in maintaining tempered glass quality standards.

What do power consumption, installed power and installed capacity of a glass tempering furnace mean?

| Power consumption of the glass tempering furnace refers to the amount of electric energy consumed in the process of tempering certain quantity of glass. The measuring unit commonly used is the kilowatt hour (KWh).

| We’ll help you meet the spec with our knowledge of the glass tempering process.

| Keeping impurities away from the glass is imperative in the glass tempering process. These impurities can cause damage resulting in a product that doesn’t live up to aesthetic standards, won’t meet a client specification or is completely unusable.

| Glass makes modern life possible, from our coffee makers, fireplaces, and induction cooktops to oil pipelines, syringes, lasers, and more.

| Skaala was founded in 1956 as a one-man company. The father of the two current owners, Hannu and Markku Hautanen, was a carpenter and already in those days, he processed glass while repairing doors and windows.

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

| “Thank you for all the services your company has provided for us. We really appreciate all, the great installation and startup of the RC200™. We are very happy with the outcome of our new furnace.”

| Furnaces are currently inspected on a regular basis with thermal imaging sensors and other techniques that heavily rely on experience of the plant personnel.

| “UniGlass is committed to stay at the forefront of the technological trends. We want to make sure we can offer our customers the total range of glass products that they need for their projects.”

| For the past five years, Nile Aluminium & Metals Company, or AluNile, has had very positive experiences with Glaston's first FC500™ tempering furnace sold outside Finland.

| Being highly focused on flat glass processes for partitioning used in the office industry, Tufwell Glass Ltd has carved out a unique and resilient position for itself in southeast region of England.

![Tempered Glass Specifications [Video & Transcript] Tempered Glass Specifications [Video & Transcript]](/sites/default/files/styles/6/public/articles/2017/HHH-Tempering.jpg?itok=P7frNEF5)