Be competitive, innovative, flexible, different … have what it takes to make a customer choose you… these are the aims of any business, but they aren’t enough and because of that in Oribay we have worked on a strategy so that they are true and tangible.

We have found the balance whereby giving our clients quality, speed and reliability has become part of our daily work. In Oribay we have found what makes us different, doing that which means that some of the biggest businesses in the world work with us.

New technology, the complexity and variety of the parts, short series have enabled us to realise the importance of being the first in the market to offer new and better products. Understanding changes and variations that exist in this sector has given us the opportunity to launch new references according to the demand of the clients. We offer a personalised product without demanding a minimum order for any of our references and we have a huge stock at our disposal in order to be able to provide, at any moment, the quantities needed by our customers.

.gif)

It is a multidisciplined team which works both in the development of new products and in the after-sales service. We are fortunate to have a technical team which is capable of producing large quantities of parts as well as smaller quantities. Our Lead-time for new developments is the shortest in the market.

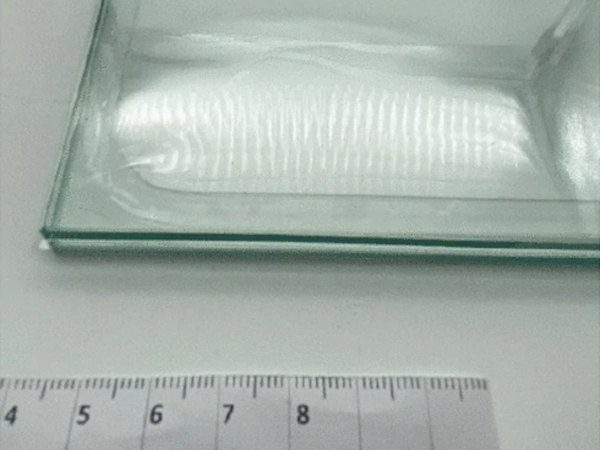

We've also been able to adapt to our clients’ requests. Evidence of this is the result of our new line of adhesives and coverings, a new family of products. Our constant research into improving complex parts has enabled us to stand out from our competitors. We invest in Research and Development and we seek perfection in each of our products.

We have chosen flexibility as a starting point, adapting to the requisites of our clients, without sacrificing the quality of our products at any moment. We want our products to be able to satisfy the demanding needs of the market.

Because we are manufacturers, we control all the processes and we are able to provide the same products in different types of materials, shapes, technologies, and coverings etc… Being able to depend on all this knowledge has been fundamental in the development of new parts. Another thing is that our prices are very competitive due to the fact that we reduce production time and costs but also because we are in direct contact with our customers, there are no middlemen.

Our specialisation has enhanced the challenge of working side-by-side with the car manufacturers, developing new parts and providing technical support in every new project.

During our more than 30 years in the market, Oribay has gained the necessary experience to be able to solve any type of requisite our client may demand. We are specialists in a complex sector, where the technical demands are very high and the results need to be perfect.

Oribay Mirror Buttons SL

www.oribay.com

commercial-marketing@oribay.com

Portuetxe bidea 18, 20018 San Sebastián (Gipuzkoa),Spain

Telephone: +34 943 310 415