VDMA Specialist Article

A smart factory works almost entirely without humans. With all its logistics systems and manufacturing equipment, the production environment organizes and manages itself. This may be hard to believe and think possible, given today's efforts to set up, repair, or even replace machines and equipment within a production line. To make this possible, it is essential that at least industry-uniform standards of communication between machines on the one hand and machines and higher- and lower-level systems, on the other hand, are used. The OPC-UA Companion Specifications (CS) task is to establish platform-independent and manufacturer-independent interoperability.

The use of OPC-UA does not mean that specific data of the machine is freely accessible to anyone who also uses OPC-UA. However, the CS describes the form in which the machines make the information available. OPC-UA provides state-of-the-art security features virtually as a side effect and makes it possible to build hierarchies.

As a result of the standardized communication for M2M, M2MES, M2ERP, M2HMI, M2Cloud, significantly faster integration and configuration of machines and systems can be achieved. This is also a great help when creating the digital twin in advance or capacity expansions. The data helps to implement Plug & Produce. It also provides relevant information about the current production data in a standardized manner and thus simplifies maintenance planning. Since this has a positive influence on plant availability and plant performance, this is also visible in one of the most important KPIs: Overall Equipment Effectiveness (OEE) increases.

The draft from May 2021 of the OPC-UA for Flat Glass Processing was adapted according to the comments received and has been published in November 2021 by the OPC Foundation as CS 40301.

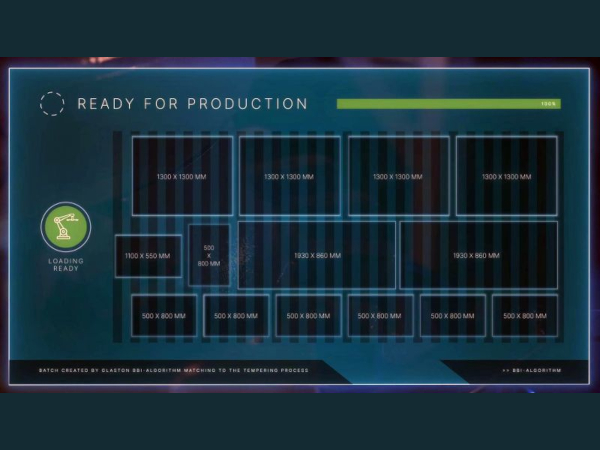

In addition to identification, the main focus is on order management.

This includes basic descriptions of order processing, creating, requesting, and sending orders, but also information on order lists and the order status. The semantics have been developed to enable the mapping of various processes along the value chain.

For VDMA members, the specification will also be made available in the familiar DaTeR database from January.