Date: 27 March 2025

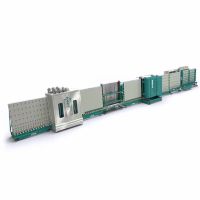

Since early 2024, we have been reporting on VITROCHAVES, one of the leading glass processing company on the Iberian peninsular, which was just about to start-up a new, fully automatic LiSEC system comprising a glass storage, glass cutting and insulating glass line. 12 months later, Mr Chaves, managing director at VITROCHAVES, is taking part in a video interview about the project process and giving exciting insights into the new production hall.

The high degree of automation at VITROCHAVES is possible due to a sorting buffer system that is coordinated by the GPS.autofab software solution. GPS.autofab aims to supply all connected machines with an optimised amount of glass. The buffer can save 4 - 6 hours of production. This also enables wastage-optimised glass cutting to be used to also consider sheet sizes for later production processes. The sheets are stored temporarily in the buffer and retrieved for further processing during the respective production batch, e.g. insulating glass production, etc. In this way, the various production processes are smoothed out and continuous production is maintained.

This ultra-modern system marks an important step in the development of VITROCHAVES and underlines its position ad one of the leading providers of flat glass for the Iberian peninsular. The fully automatic factory enables efficient production and high quality end products, from which the VITROCHAVES customers benefit.

Mr Chaves, managing director at VITROCHAVES, is talking about the project process and giving exciting insights into the new production hall.

Photos © LiSEC

600450

600450

Add new comment