Date: 4 October 2016

Vitro has closed the acquisition of PPG’s flat glass business. Vitro also announced an investment in a jumbo magnetron sputtered vacuum deposition (MSVD) coater for the newly acquired business, which will be the largest coater in North America.

The transaction was approved by the governing bodies of both companies and by the relevant regulatory authorities in the United States and Canada.

The business includes PPG’s entire flat glass manufacturing and glass coatings operations in the United States and Canada, which includes four manufacturing plants with a total of five flat glass furnaces; a research and development center; and four distribution and fabrication facilities in Canada.

New jumbo coater investment

The company also announced the expansion of its coating production capability with the construction of a jumbo MSVD glass coater, which will be built at an existing location of the newly acquired business. MSVD coaters are used to produce high-performing, energy-efficient low-emissivity (low-e) glass.

The projected coater will be capable of coating jumbo sizes, and we expect it to be the largest of its kind in North America.

Adrian Sada Cueva, chief executive officer of Vitro, said, “The company’s Flat Glass Division has become a key business for Vitro, and this investment will allow us to strengthen it by offering a wider set of solutions to our customers. Through this investment, we will create value for our shareholders and our new flat glass business will reassert its standing as the leader in the commercial glass segment in North America.”

History

From humble beginnings in 1883 as the Pittsburgh Plate Glass Company, PPG (now Vitro Architectural Glass) became a world leader in glass manufacturing, shipping glass to more than 80 countries and producing some of the industry’s most advanced architectural glasses.

PPG (now Vitro Architectural Glass) perfected the manufacture of plate glass in the 1920s, paving the way for glass to be used on landmark skyscrapers throughout North America.

One of the most recognized is Bank of America Tower in Dallas (left), which features an iconic green silhouette at night. Known as Interfirst Plaza when it opened in 1984, the 72-story skyscraper was constructed with SOLARBAN® 560-8 TWINDOW® glass.

Thirty years later, it remains the tallest building in the city and the third tallest in Texas. Solarban glass also is featured on San Felipe Plaza, Houston (right), another Lone Star state landmark.

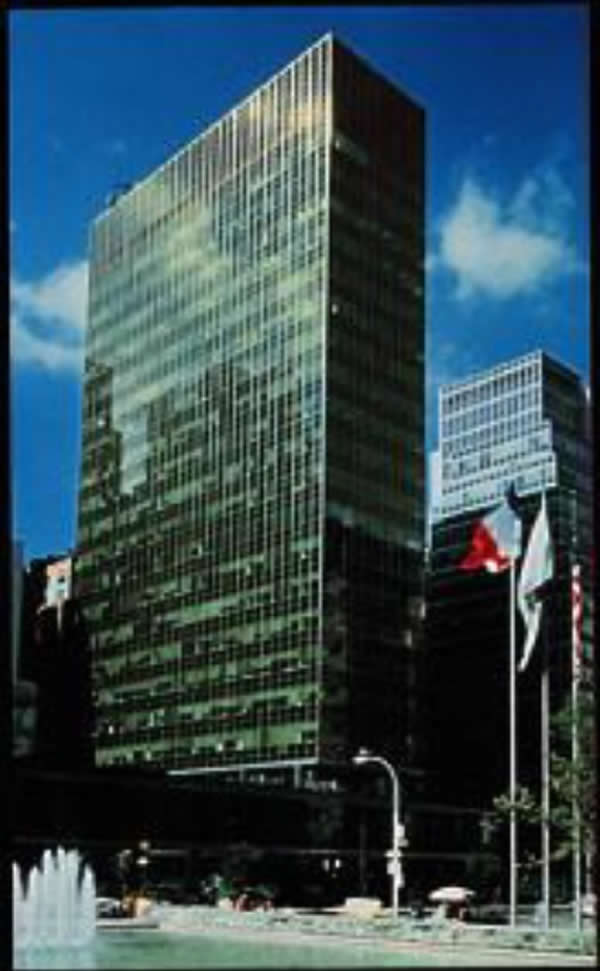

Lever House in New York City, one of America’s first great modernist glass and steel structures was built with SOLEX® glass by PPG (now Vitro Architectural Glass) in 1952. Introduced in 1934, Solex glass is considered the world’s first “environmental” glass for its ability to absorb solar heat and keep it from entering buildings.

With its distinctive light-green tint, Solex glass enabled architects, for the first time, to design buildings with large expanses of glasses without concentrating the sun’s heat indoors. Solex glass (now known as SOLEXIA® glass) remains a popular choice for contemporary architects because of its good looks.

Recent Projects

The Tower at PNC Plaza features an innovative double-skin façade, one of the first of its kind in North America, which is designed to help the building naturally ventilate for 42 percent of the year.

The inner and outer curtain walls feature SUNGATE® glass by PPG (now Vitro Architectural Glass), which was selected for its ability to trap furnace heat in the winter; and STARPHIRE ULTRA-CLEAR™ glass, which was specified for its ability to transmit high levels of daylight.

SOLARBAN® Glass Projects

In 1964, PPG (now Vitro Architectural Glass) introduced SOLARBAN® glass, one of the first coated glasses engineered expressly to block solar radiation and thereby reduce air-conditioning-related energy consumption.

In 2000, the Solarban glass name was reintroduced as the brand name for a new category of solar control low-emissivity (low-e) glasses, which continue to set the standard for energy-saving performance in the architectural glass industry.

Solarban glass is integral to Thanksgiving Tower (left) and Citigroup Center (right). Thanksgiving Tower opened as Dallas’s second tallest building in 1983.

Highlighted by its soaring reflective glass curtain wall, the 50-story building, now the city’s eighth tallest, is distinguished by its distinctive “sawtooth” exterior, which was designed to create 16 corner offices on each floor.

Citigroup Center, formerly known as the Wells Fargo Tower, has been a fixture on the Los Angeles skyline for more than 30 years. Designed by A.C. Martin and opened in 1979 as the Wells Fargo Bank Building, Citigroup Center gained prominence as the television home of the 1980s hit series, “L.A. Law.”

The industry’s first triple-silver-coated, solar control low-emissivity (low-e) glass, SOLARBAN® 70XL glass, launched at the 2005 GreenBuild International Conference and Expo, features an unprecedented combination of solar control and visible light transmittance.

The transparency of Solarban 70XL glass is a highlight of the 26-story City Center Plaza, which rises above Bellevue, Washington. The building features curved silver arcs running up both facades and offers stunning views of Lake Washington, Mr. Rainer and the Cascade Mountains.

Solarban 70XL glass helped City Center Plaza achieve LEED® certification at the Gold level.

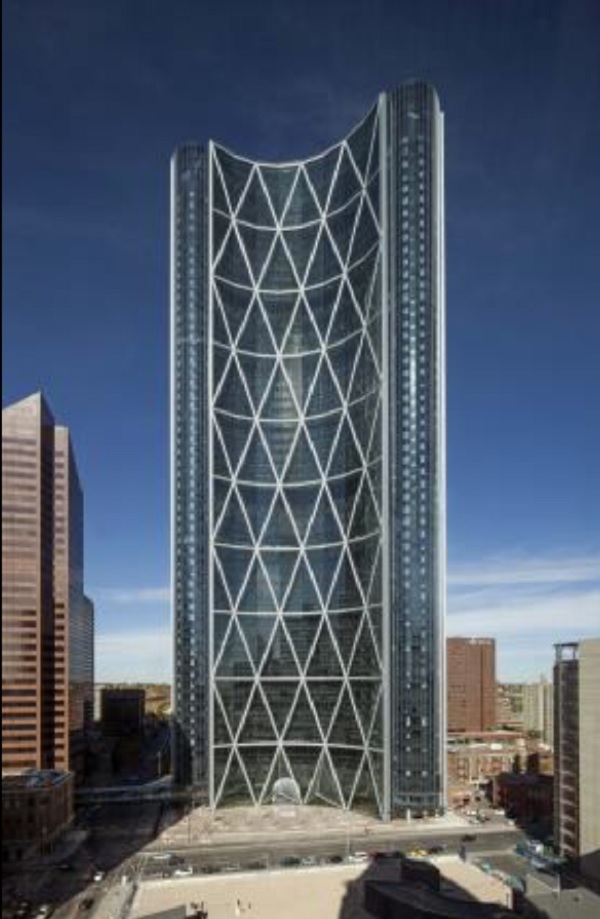

At a height of 775 feet, The Bow, headquarters for EnCana Corporation, is Calgary’s tallest building. The 58-story structure draws its name from both its stunning, crescent-shaped façade and its location along the city’s Bow River.

The distinct concave profile, fabricated largely from SOLARBAN® z50 glass by PPG (now Vitro Architectural Glass), is designed to help the tower deal effectively with winter and summer wind patterns and to enhance its sustainability and energy performance.

The Bullitt Center in Seattle, regarded as the “greenest” structure of its kind in the world, was constructed with SOLARBAN® 60 solar control, low-emissivity (low-e) glass and STARPHIRE ULTRA-CLEAR™ glass by PPG (now Vitro Architectural Glass).

The signature design element of the six-story office building is the “irresistible stairwell,” which features STARPHIRE® glass to frame panoramic views of Seattle and Puget Sound. The irresistible stairwell saves energy by encouraging building occupants to use stairs instead of the elevator.

The Center for Sustainable Landscapes at Phipps Conservatory, Pittsburgh, became the first building to earn a four-star rating through THE SUSTAINABLE SITES INITIATIVE™ program.

The center, which also is LEED® certified at the Platinum level, was constructed with SOLARBAN® 60, SUNGATE® 500 and STARPHIRE ULTRA-CLEAR™ glasses by PPG (now Vitro Architectural Glass).

One of the world’s first certified “living buildings,” the structure is designed as a long, window-lined rectangle, enabling natural light to penetrate the deepest parts of the building to foster plant growth and reduce reliance on artificial lighting.

The 450,000 square-foot expansion of Nemours Alfred I. DuPont Hospital for Children in Wilmington, Delaware, features SOLARBAN® 70XL glass on the ground floor façade, and Solarban 60 glass and AZURIA® performance-tinted glasses on floors two through five.

The high-performance glasses give the hospital a jewel-like appearance, increase patient comfort and reduce heating and cooling costs year-round.

Vitro Glass Technology Center

Harmar Township, Pennsylvania

The Vitro Glass Technology Center in Harmar Township, Pennsylvania, formerly the PPG Glass Business and Discovery Center, became the U.S. home of Vitro Architectural Glass on Oct. 1, 2016, when Vitro completed its acquisition of PPG’s Flat Glass business unit.

Adrián Sada González, chairman of the board of directors for Vitro, said the acquisition of PPG glass brings together more than 200 years of experience in the production of glass and boosts Vitro’s presence in North America, one of the most important and high value-added markets in the world.

Vitro was founded in 1909 and PPG (originally Pittsburgh Plate Glass) in 1883.

The Vitro Glass Technology Center in Harmar Township, Pennsylvania, near Pittsburgh, formerly the PPG Glass Business and Discovery Center, opened in 1958. More than 500 patents have been issued to employees of the center over the past 30 years, with more than 200 of them still active.

The facility became the U.S. home of Vitro Architectural Glass on Oct. 1, 2016, when Vitro completed its acquisition of PPG’s Flat Glass business unit. The combination of talent from Vitro and PPG glass will keep the newly united organization on the forefront of glass innovation worldwide.

The glass-walled Vitro Glass Technology Center in Harmar Township, Pennsylvania is one of the world’s most sophisticated hubs for glass technology, research and development. The facility was acquired by Monterrey, Mexico-based Vitro on Oct. 1, 2016, along with five glass production furnaces in the U.S. and four distribution and fabrication facilities in Canada.

Located 15 miles northeast of Pittsburgh, the Vitro Glass Technology Center in Harmar Township, Pennsylvania has been the development site for industry-leading glass brands such as SOLARBAN® solar control, low-emissivity (low-e) architectural glasses, SUNGATE® automotive glass and antenna windshields and INTERCEPT® insulating spacers for residential windows.

Monterrey, Mexico-based Vitro, which was founded in 1909, assumed operation of the facility on Oct. 1 as part of its acquisition of PPG’s Flat Glass business unit, with the goal of expanding its legacy of research and development.

An engineering specialist uses a computer to define the parameters of a coating to be deposited on architectural glass in a lab-scale vacuum coater at the Vitro Glass Technology Center in Harmar Township, Pennsylvania, near Pittsburgh. The device facilitates basic research and the production of prototype coatings for architectural glass.

A scientist loads a tinted glass sample into a spectrophotometer at the Vitro Glass Technology Center in Harmar Township, Pennsylvania.

The device measures the spectral reflectance and transmittance of coated and uncoated glass, which can help define aesthetic qualities such as perceived reflected and transmitted color, and offer preliminary insights into performance parameters such as solar heat gain coefficient, shading coefficient, U-value and others.

Technicians at the Vitro Glass Technology Center in Harmar Township, Pennsylvania use a digital electronic microscope to examine the topography of a coating on an architectural glass sample.

The topographical analyses, which can be rendered in three dimensions (as pictured at left) or as a color map (as pictured at right), are useful for the formulation and refinement of new coatings and for diagnosing coatings-related problems on a production line.

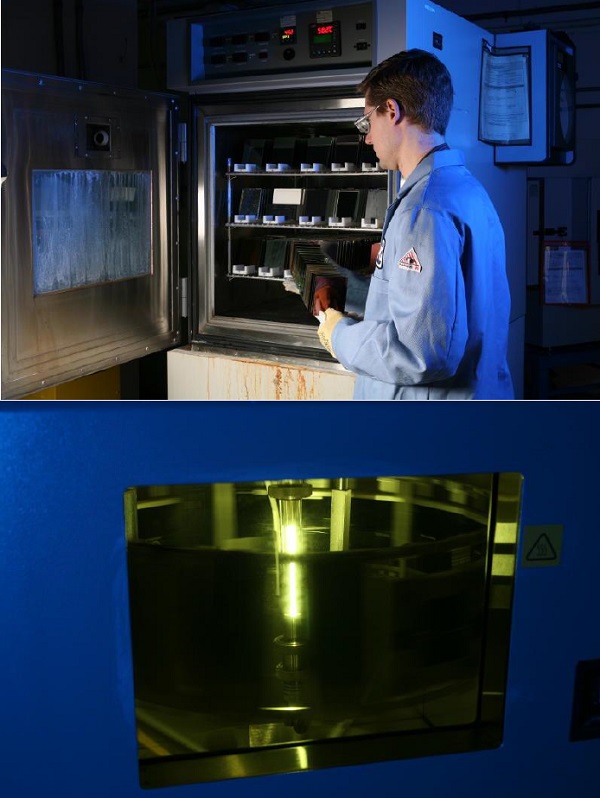

A researcher (above) places architectural glass samples into an environmental test chamber at the Vitro Glass Technology Center in Harmar Township, Pennsylvania. The device is used to assess the environmental durability of coated and uncoated glasses in extreme temperatures and humidity.

Vitro Architectural Glass operates similar chambers in the facility that test for exposure to salt spray, ultraviolet (UV) light, corrosive materials and intense light from the visible, UV and near-infrared portions of the electromagnetic spectrum.

A glass sample (below) is exposed to intense visible, UV and near-infrared light generated by a zenon-arc lamp inside a different environmental test chamber. This accelerated testing enables product developers to assess the impact of intense light on architectural glass products.

PPG (now Vitro Architectural Glass): 130 Years of Leadership and Innovation

1883

The Pittsburgh Plate Glass Company is founded, establishing the first plate glass plant in the United States.

1920s

PPG (now Vitro Architectural Glass) becomes one of the first companies to successfully mass-produce glass. The patented Pittsburgh process accelerates production and minimizes waves and other imperfections common to plate glass. Perfecting the manufacture of plate glass paved the way for it to be used on North America’s landmark skyscrapers.

1934

PPG (now Vitro Architectural Glass) introduces SOLEX® glass, the industry’s first “environmental” glass. With its distinctive light-green tint, Solex glass enables architects, for the first time, to design buildings with large expanses of glasses without concentrating the sun’s heat indoors. The product, now known as SOLEXIA® glass, remains popular with architects today as part of Vitro’s collection of blue and green performance-tinted glasses.

1945

PPG (now Vitro Architectural Glass) unveils TWINDOW®, one of the world’s first commercialized double-paned insulating glass units, which foreshadows the green building movement by promising to keep “homes warmer in the winter and cooler in the summer.”

1952

SOLEX® glass (now SOLEXIA® glass) is installed on the historic Lever House in New York City, launching the era of the glass-clad modernist building.

1963

PPG (now Vitro Architectural Glass) becomes the first glass manufacturer in the United States to use the float glass process, which remains the predominant method of making glass today.

1964

PPG (now Vitro Architectural Glass) introduces SOLARBAN® glass, one of the first coated glasses engineered expressly to block solar radiation and thereby reduce air-conditioning-related energy consumption. Minoru Yamasaki, who that same year designed the iconic World Trade Center towers in New York, selects Solarban glass for the The Mutual of Omaha

Regional Office (now Colonnade Plaza) in Miami, the first major building for which the glass was specified.

1972

PPG (now Vitro Architectural Glass) introduces SOLARCOOL® reflective glasses.

1974

PPG (now Vitro Architectural Glass) glass is installed on Sears Tower (now Willis Tower) in Chicago, the tallest building in the United States.

1989

AZURLITE® glass (now AZURIA® glass), a spectrally selective, blue-green glass, is introduced. The famed Atlantis Resort in the Bahamas becomes one of the first large installations of the product.

1990

STARPHIRE ULTRA-CLEAR™ glass debuts at GlasTec ‘90 in Dusseldorf, Germany. Because of its exceptional clarity, STARPHIRE® low-iron glass is widely used as display glass, perhaps most famously at the National Archives in Washington D.C., where it protects the original drafts of the Declaration of Independence, the U.S. Constitution and the Bill of Rights. More than 25 years after its introduction, Starphire glass remains the industry’s clearest, most transparent float glass.

2000

SOLARBAN® glass, originally launched in 1964, is reintroduced as the brand name for a new category of solar control low-e glass, which continues to set the standard for energy-saving performance in the architectural glass industry.

2005

SOLARBAN® 70XL glass, the industry’s first triple-silver-coated, solar control low-e glass, is launched at the GreenBuild International Conference and Expo. With the industry’s highest light-to-solar gain (LSG) ratio, Solarban 70XL glass features an unprecedented combination of solar control and visible light transmittance.

2010

SOLARBAN® R100 glass is introduced to provide high visible light transmittance with neutral reflectivity.

2015

SOLARBAN® 90 glass, which combines exceptional solar control performance with the aesthetic appeal of clear glass, debuts, enabling architects to design buildings with larger expanses of glass with improved occupant comfort.

2016

PPG’s flat glass business unit is acquired by Vitro, a leading glass manufacturer founded in Monterrey, Mexico in 1909. Together, Vitro and PPG possess more than 200 years of glass manufacturing, research and product development expertise, and form one of the largest and most innovative glass companies in the world.

600450

600450

Add new comment