Date: 11 February 2019

Our recent investment at our 50,000 sq.ft production plant is a testament to that belief and part of our ongoing strategy for providing unbeatable uPVC products to every one of our customers.

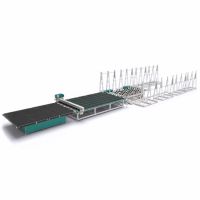

The machinery installed was our fourth state of the art BDM cutting machine, which has further allowed us to scale our production. With the capacity to complete over 4000 frames per working week, you’ll never be left waiting with TruFrame.

What does this mean to our customers

The BDM cutting machines not only speed up our process but also enable our dedicated fenestration team to produce frames with an extremely low tolerance for inaccuracies. Our cutting and prep centres are accurate to ± 0.2mm, meaning that you can be assured that our windows and doors meet your requirements every time.

Delivery times are also a big beneficiary of our investment. With faster turnaround times, our clients get their orders sooner, meaning less time spent waiting for your frames and ultimately, happier customers.

Security is a prime concern for any home or business owner and at TruFrame we take security seriously. Not only do we partner with Yale to provide the most comprehensive locking systems on offer, but our manufacturing process combined with the Liniar uPVC system produces a frame which is recognised for its security by BSI, and Secured by Design.

To learn more about our secure windows and doors, visit our product pages.

600450

600450

Add new comment