Date: 20 February 2012

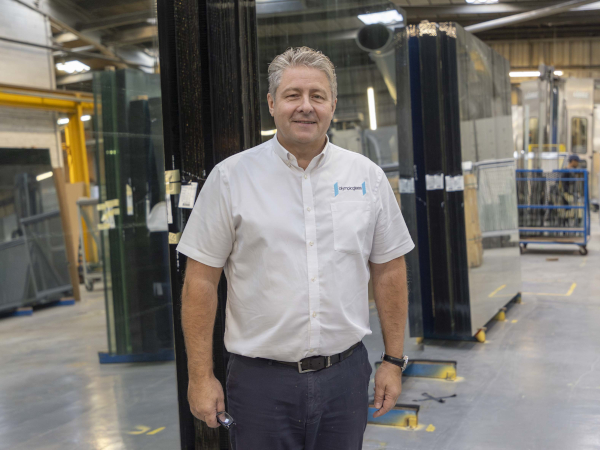

The new laser system from the company has been designed specifically to eliminate sorting issues in relation to triple unit production and can be incorporated into either new or existing lines at a realistic cost. Steve Goble, Managing Director Hegla UK comments, “With triple glazing being in its infancy on the UK market and way behind its European counterparts, it is important to adapt to positive change and assist progressive companies to invest wisely. As government legislation progresses, it will become increasingly important for manufacturers to be able to produce triple units as consumer education and drive will steer the industry.”

The Hegla team considers that whilst there may be many in the industry who will cogitate about triple glazing, there will also be those who realise that sensible investment levels will not only improve production standards and minimise error but that laser investment will greatly reduce overhead costs. As 50% more glass will be required for triple glazing production, equally this will need to be accurately marked. Obviously standard seal units have two pieces of glass with triple units having three pieces. Production therefore, will be more complex with shaped units, combinations of glass coatings and possibly combinations of cavity. Accommodating human error into the production process through sequencing complications could prove to be a very costly procedure, so it would be far better to guarantee to get it right.the first time round. Identifying the glass for the units correctly, in relation to the correct coatings and the various permutations that will be used in triple glazing production will be essential.

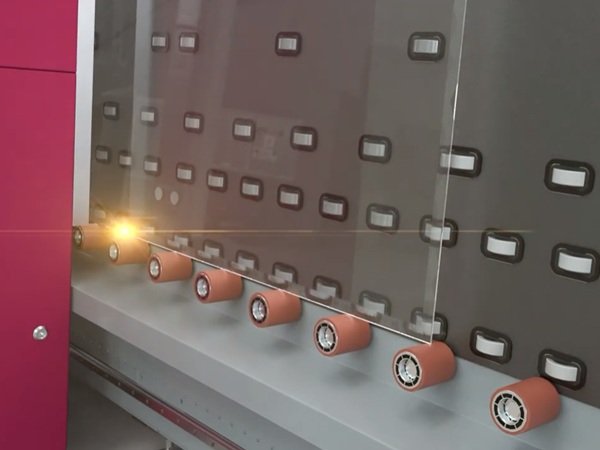

This element of the production process is where Hegla’s unique laser marking systems will come into its own and have an advantage over other equipment on the market. Faster cutting tables may also be required. Hegla’s laser marking capabilities which have been meticulously designed by German engineers enables the glass to be marked automatically before it is cut. Laser marking on the cutting table guarantees the correct production data is put onto the correct piece of glass. Marker pens are not required, with ghosting eliminated on coated products. Additionally, if the glass has the correct address for its production route, sequencing should be guaranteed with coatings the correct way round and cavities in the correct position in relation to the coatings.

The option of the laser from Hegla to reverse-etch an image or data is paramount to the combinations above. Within a short period of time it is expected that legislation will probably be introduced to accommodate industry standards and the changes these will bring for manufacturers who diversify into triple glazed unit production will be vast. Hegla is continually looking at ways to move forward with cutting technology with faster loading, faster cutting, glass identification, sorting systems, sub plate storage all being important for future sealed unit development and offering financial and real time benefits. For more information please call: 01908 261933

Add new comment