Others also read

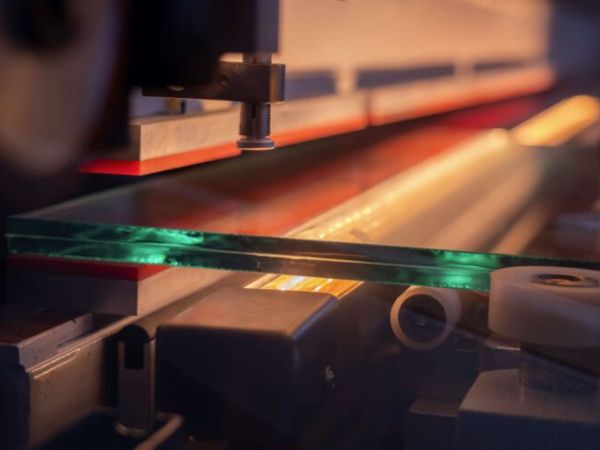

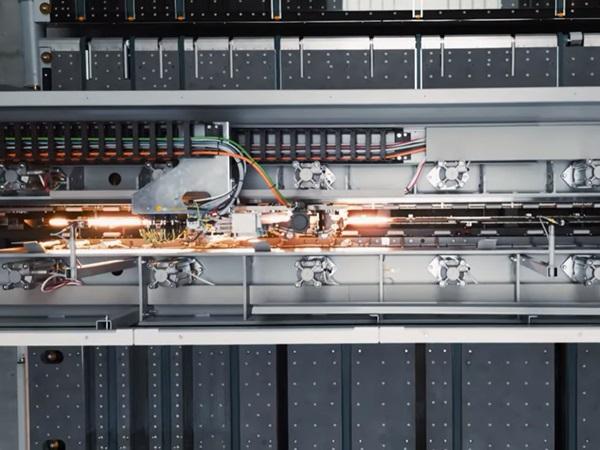

The cutting of thin glass is extremely demanding! That’s why HEGLA has designed a Galactic float glass cutting system specially for the needs of thin glass.

Unlock the potential of your existing machines with our innovative retrofits. These five features allow you to benefit from our continuous development and make the LiSEC machines in your machine park future-proof.

Vidres Ponent renews the process of storage, loading and cutting of glass with TUROMAS technology, optimizing the storage capacity in more than 1000m2.

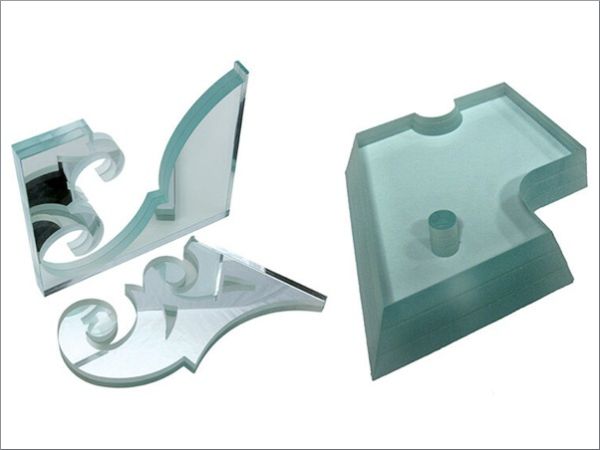

CMS Glass Technology renews the waterjet cutting experience with easyline and e-pump, the perfect solution for those looking for versatility, precision and efficiency.

Automatic cutting and breaking of Low-E and solar control glass

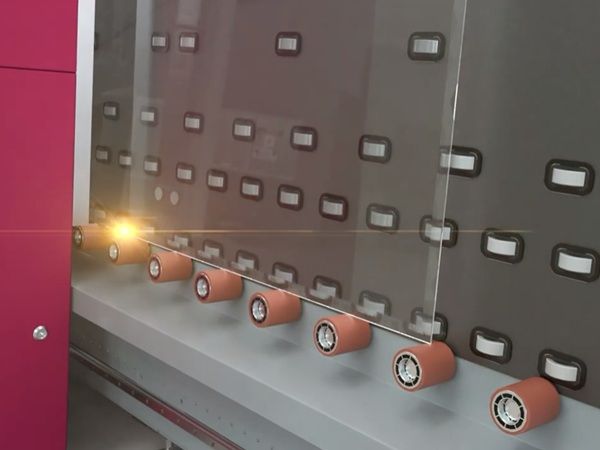

The LSP-A offers a space-saving and precise solution for flat glass laser processing. With its compact design and movable laser head, it enables unique designs and structures on glass surfaces.

TUROMAS responds to one of the current needs of the glass market with the new cutting system for laminated safety glass railings.

With a focus on the future, Olympic Glass has invested in a combined float and laminated glass cutting line from LiSEC.

CMS Glass Technology has consolidated its presence in the laminated glass sector, distinguishing itself for its innovation and the development of advanced solutions.

Longer lifetime, higher reliability

IGE Glass Technologies, Inc. announces the formal signing of a long-term exclusive distribution contract with PRC Laser Europe for the North American market.

Covipor reinforces its production capacity with TUROMAS technology.

Automatic cutting and breaking of Low-E and solar control glass

TUROMAS returns to Glasstec, the most important trade fair for the flat glass industry

The orders include several Glaston CHAMP EVO automotive glass pre-processing lines, and are booked in Glaston’s Q3 and Q4 2024 order book.

Discover the NEW CMS cutting table for laminated glass together with CNC machines taktika and electa

Experience the fastest highly automated and optimised laminated glass cutting system, live in action at glasstec in Düsseldorf at the LiSEC stand in Hall 17 / A64!

CMS sprint is a 5-axis CNC cutting machine equipped with a diamond disc, designed to boost productivity in the processing of laminated, fire-resistant, or safety glass.

Tristar Glass has enhanced its Dallas plant's production capacity by acquiring advanced smart machinery from Turomas, including two RUBI 517C cutting tables and an SR-07 storage system.

This year, Schraml will once again be exhibiting at the LiSEC stand in Hall 17 / Stand A64 at glasstec from 22-25 October in Düsseldorf.

Turomas will be at the Glasstec trade fair, ready to showcase the latest advancements in technology and machinery.

What can visitors to the LiSEC stand expect in terms of robotics?

"THE TECHNOLOGY LEADER" ® sets its sights on Texas for the biggest glass trade show in North America.

HEGLA's laser expert, Dr. Thomas Rainer, provides exciting insights into their products.

The fastest laminated glass cutting machine for series production in action!