Others also read

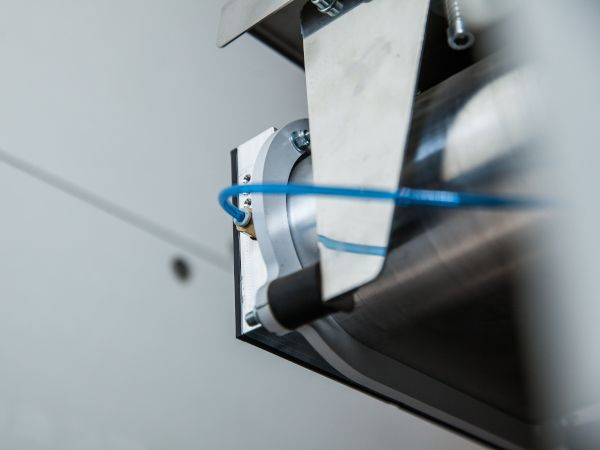

Sparklike Laser Integrated™ is a fully automated, non-destructive gas measurement system designed to be integrated directly into insulating glass (IG) production lines.

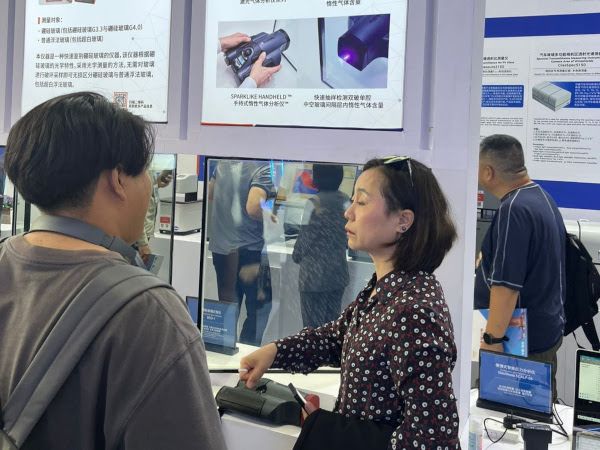

Sparklike continues to strengthen its global presence, connecting with industry professionals and showcasing its innovative gas measurement solutions for insulating glass (IGU) quality assurance.

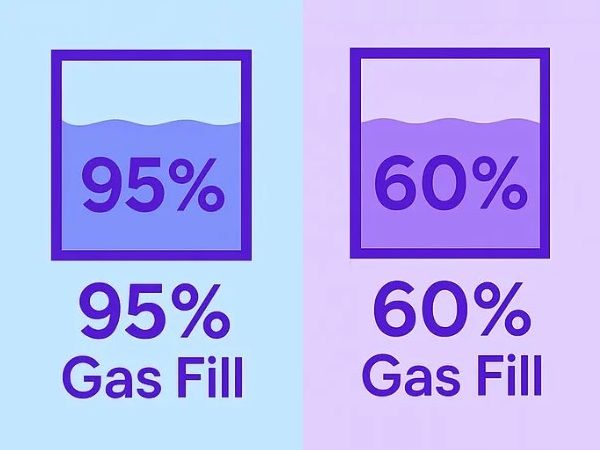

The quality and durability of insulating glass units (IGUs) rely on precise manufacturing processes, especially when it comes to gas fill levels and leakage rates.

Sparklike technology helps IGUs stay durable and energy-efficient by preventing gas leakage.

This autumn, Sparklike has been actively present at major international trade shows, reinforcing its commitment to innovation and global collaboration in the glass industry.

Sparklike now offers a free online IG Configurator, helping manufacturers quickly check if their insulating glass units are compatible with Sparklike Laser for accurate, non-invasive gas measurement.

“Our customers can be sure that whatever they ship out of their door is high quality – with no complaints from their customers.”

– Peter Pfannenstill, Co-Founder & VP Sales at Softsolution

– Peter Pfannenstill, Co-Founder & VP Sales at Softsolution

Accurately measuring argon in insulating glass units (IGUs) is essential to ensure energy efficiency and sustainability—here’s how advanced testing methods, including Sparklike solutions, make it possible.

Thermoseal Group’s Sales Director, Mark Hickox, explains why having an in-house lab is vital to the component manufacturer’s success.

HORN is proud to announce that the HORN HRD-BEAM contactless glass level measurement system has already been installed 20 times on glass furnaces worldwide.

Since 1993, Huadong Coating has delivered top insulating glass solutions—now enhanced with Sparklike technology for precise gas measurement.

Learn how to get the most accurate results with Sparklike Laser devices for non-invasive IGU gas concentration measurement.

Traditional Egyptian Glass Techniques realized by Cutting-Edge Software.

Sparklike launched the 2025 trade fair season with key appearances at China Glass 2025 in Beijing and Glass Performance Days in Tampere.

Accurate gas fill measurement is key for IGU quality - here’s how ASTM E2649-20 and Sparklike Handheld™ make it easier.

To guarantee long-term performance and customer trust, Weihai Blue Star turned to non-invasive gas measurement with Sparklike Handheld—setting new standards in insulating glass quality.

As one of the leading glass manufacturers in Europe, Pilkington Poland, part of the global NSG Group, places high emphasis on quality and performance.

Maintaining the performance of insulating glass units over time is key to energy efficiency. Discover how Sparklike technology helps monitor and manage IGU degradation effectively.

This case study involving two UK-based companies demonstrates the critical importance of precise gas measurement and proper calibration in maintaining consistent product quality.

Sparklike is pleased to announce that Trend Trade & Trans Trade Intl Co., Ltd. has been appointed as its new official distributor in South Korea.

Optris Expands Infrared Temperature Measurement Devices with Network-Enabled Protocols

To stay ahead in a highly competitive industry, Guangdong Zhongrong Glass is investing in cutting-edge LiSEC technology.

Making sure insulating glass units (IGUs) meet high standards is essential for both manufacturers and installers. The gas fill level in IGUs is key to providing good thermal performance and energy efficiency.

Glasstech Asia 2024 showcased glass industry innovations, with Elegant IG emphasizing quality and precision in insulating glass measurement as Sparklike's regional distributor.

The latest evaluation by ift Rosenheim confirms that the Sparklike Laser Portable 2.2™ meets the accuracy requirements of EN 1279-3 for measuring gas concentrations in insulating glass units (IGUs).