Others also read

To support ambitious growth plans, the Dutch company Buys Glas didn’t just expand its production space, they invested in smart automation.

The HUB is a central component of the global LiSEC strategy, with around a quarter of the world's population living in this region.

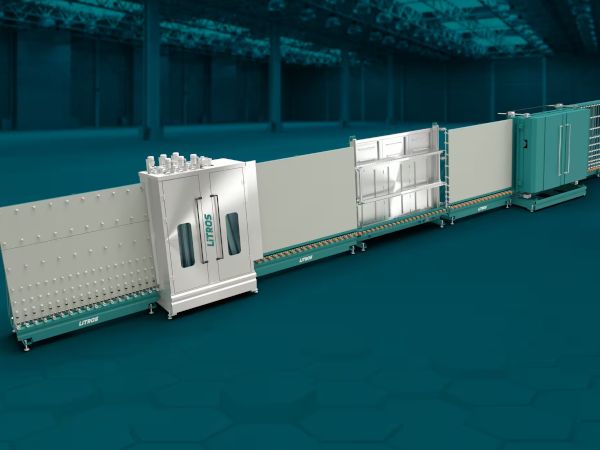

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames.

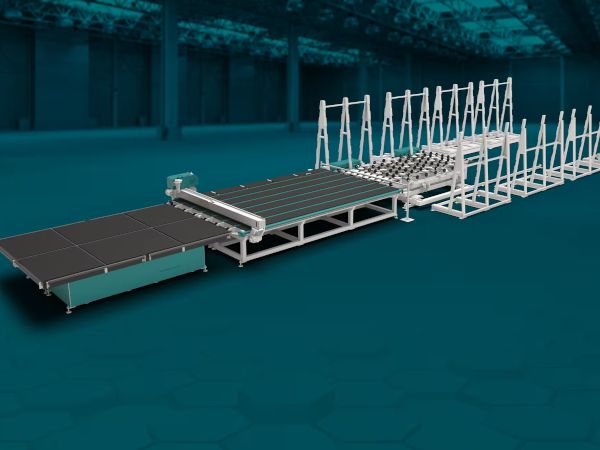

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass.

TSS is not just technical support – it is a forward-looking partner for realising high performance production solutions.

When we think about industrial technology, we often imagine standardised production lines, catalogues with predefined models, one-size-fits-all solutions. This is a logic that does not belong to SCHIATTI.

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

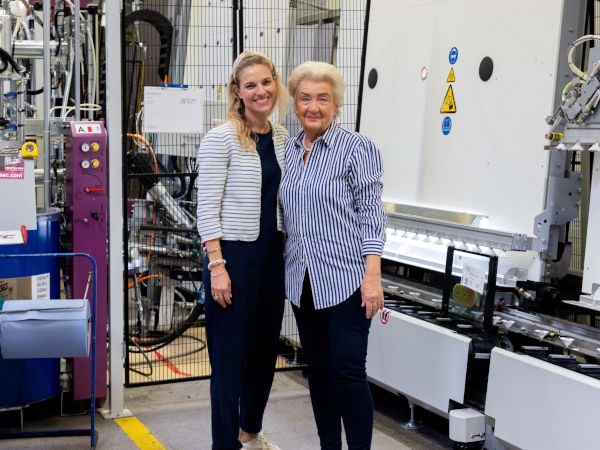

When production gets more complex, strong partnerships make it sustainable.

CMS aura is the vertical dry seaming machine designed for those seeking efficiency, simplicity, and savings in the glass processing workflow.

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

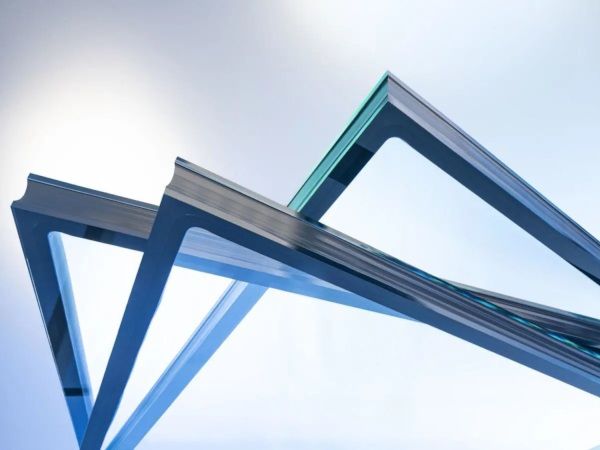

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

HEGLA is expanding its portfolio by entering the field of wet glass machining through the acquisition of RS technology, strengthening its capabilities in advanced glass processing and automation solutions.

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.

NorthGlass has successfully delivered a fully automated smart manufacturing line for a key client in Vietnam, enabling high-precision, high-volume production that meets the demanding standards of global home furnishing brands, including IKEA.

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

LiSEC was named "Austria's Best Managed Company 2025" and took second place in the large companies category in Lower Austria at the prestigious Austria's Leading Companies Award.

The 2025 edition of GlassBuild America has concluded in Orlando, marking a record-breaking year for North America’s leading glass industry exhibition, which welcomed the highest number of exhibitors and visitors to date.

On 6 and 7 November, LiSEC welcomed more than 60 customers from Central and Eastern Europe and the Commonwealth of Independent States (CIS) region to Seitenstetten.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

From the GlassBuild 2025 show floor in Orlando, Forel & Quanex are highlighting the innovative collaboration that is bringing automation and spacer performance to the next level.

Forel introduces a new manufacturing solution for Triple Thin IGUs with Flexible Spacer, combining advanced automation, precision, and efficiency for next-generation insulating glass production.

New model FG for fast grinding and simultaneous edge seaming.

The strengths and expertise of the MADE products to date will be bundled under the LiTROS brand, developed further and opened up to new target markets.