Others also read

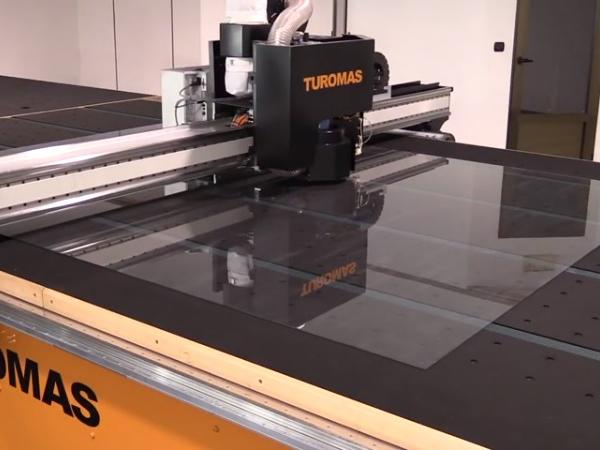

Tvitec, one of Europe’s leading companies in the flat and curved glass sector, has acquired a new TUROMAS cutting line for laminated glass.

TUROMAS has produced and installed the new laminated glass cutting table which the glass manufacturer has added to its high-tech park.

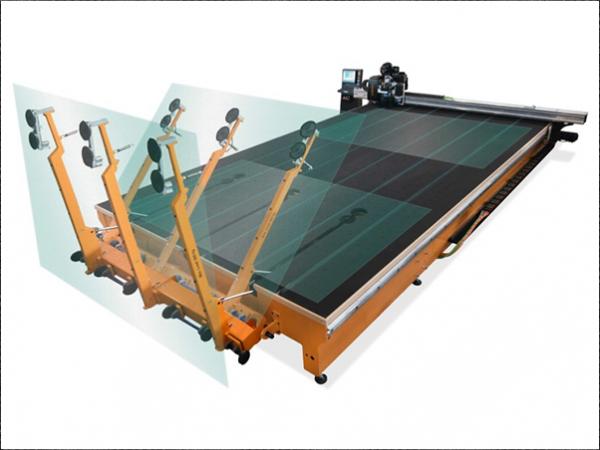

The LAM 500 series is aimed at companies that need maximum productivity and automation. Designed to work integrated in a laminated cutting line or as part of a mixed line.

New laser separation technology now offers the potential to significantly shorten the processing cycle and improve edge quality.

High performance CNC machines and unique integrated lines for glass processing.

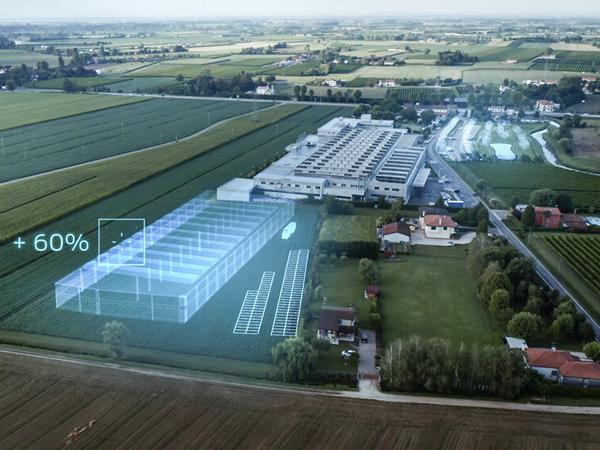

The enlargement of the Forel production plant (Treviso-Italy) is set to begin in 2021.

Without a digitizing solution, customer supplied templates can often be a difficult task, as the Swiss company FRANZ GYSI AG can confirm.

Live demos, talks with our experts and in-depth analysis of the main trends of the glass market.

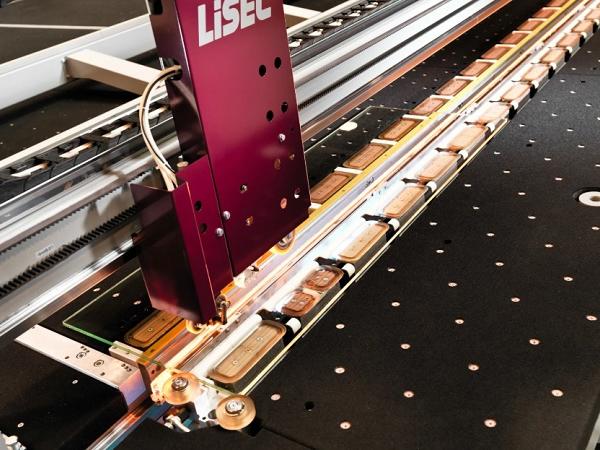

Between 27 and 30 October 2020, the virtual LiSEC Campus will be welcoming visitors from around the world.

With a long-established history in glass machinery manufacturing, HEGLA has developed a fully automated, in-line, blade trimming system that provides greater accuracy and speed.

The StreamLam is a new, holistic cutting system for laminated glass.

What C.Bergmann appreciates most about the 32 years of cooperation with LiSEC is the consistently high quality of the long-lasting LiSEC machines and the tangible proximity to the customer.

Localised stresses in laminated glass can cause faulty breakages during cutting. The modern suction cup mechanism from LiSEC helps to reduce the numbers of losses.

The TUROMAS loading system offers multiple benefits for glass processing companies, including productivity increase, optimization of plant layout, economic savings or factory safety.

The RUBI 500 SERIES is aimed at companies that need maximum productivity, automation, efficiency and precision.

Cottrill & Co. offers two very unique online auctions. Lisec, Bystronic, Tamglass, Hegla and other machinery.

Supertuff and LiSEC have been working together for 20 years now.

Cutting 0.030 inch thick (0.76mm) EVA laminated glass with automated Eastman C125 conveyor system.

The cooperation between Glass Systems and LiSEC started when the new production facility in Swansea was opened.

Hegla UK, has now relocated to new premises as part of a larger expansion programme.

The quality of the cut is what makes a cutting process more productive and efficient.

After the recent events happening on a global scale, by the spread of the global pandemic of the COVID-19 virus, TUROMAS has implemented a series of measures to continue with the activity and obligations in a normal and in a responsible manner.

Gennady Bugrov (RGC): “Organisation and efficiency are our greatest strengths. And now we're investing in the future”

Mr Rákosy is generally extremely satisfied with the cooperation with LiSEC. In particular with regards to service and spare parts availability.