Others also read

New laser separation technology now offers the potential to significantly shorten the processing cycle and improve edge quality.

High performance CNC machines and unique integrated lines for glass processing.

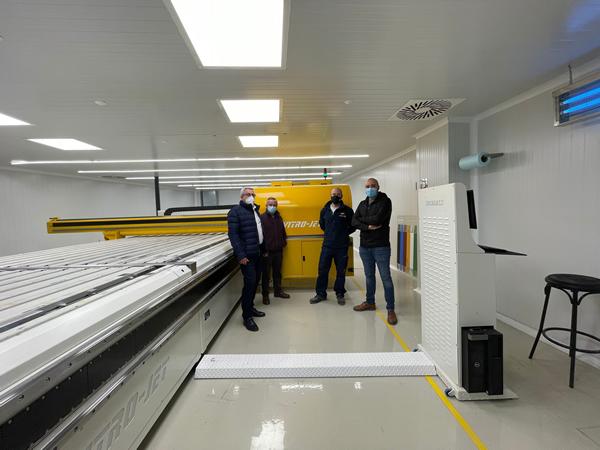

Tecglass developed a showroom which allow them to show their processes to customers and leads, and most importantly, help them fully experience the digital printing process.

With this investment, Val y Val will be able to produce laminated glass with great precision, reliability and great savings in production costs.

Cristasón, in an interview published in the online magazine Vidrio Perfil, shares their satisfaction at the purchase of a new oven.

Tecglass installed the novel digital printer Vitro-Jet The Thunder, a turn-key solution manufactured in-house for mass production in automotive and architectural glass.

Tecglass develops Jetver HA, a laser-focused ink for the home appliances industry.

We demonstrate the superior reliability and behaviour of AB-AR over other structural interlayers

To celebrate the centennial anniversary of Hornos Industriales Pujol, the company has launched its most technologically advanced oven on the market.

Show Room Automotive Glass Mass Production.

Joe Khoury explains why his company advertises itself as the leading curtain wall consultant in Asia.

Three questions to Reinhard Pfeiffer, Deputy CEO of Messe München.

Pujol has developed a new oven that can carry out high-quality chemical tempering of glass. This oven is designed to work with any type of glass, thickness or shape.

Mappi met Nermin Berbic to talk about his company, and their recent improvement: an all new tempering furnace, a Mappi Fox 1500x3000.

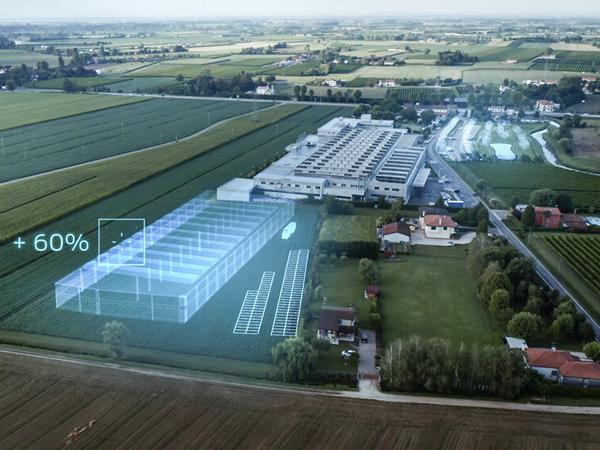

The enlargement of the Forel production plant (Treviso-Italy) is set to begin in 2021.

Without a digitizing solution, customer supplied templates can often be a difficult task, as the Swiss company FRANZ GYSI AG can confirm.

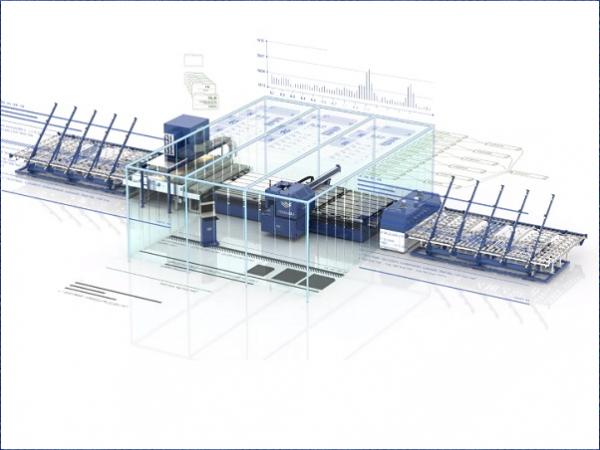

The LiSEC partners Schraml Glastechnik, Glastronic, Glastech and Cericom play an important role in the LiSEC "all in one solutions" philosophy.

The furnace is designed in appliance with the most advanced technology and a maximum melting output of 290 t/d to produce either 290 t/d flint or amber glass or 280 t/d green glass.

Learn why Trosifol® PVB interlayer for laminated safety glass is so special.

A year ago, Hitech Safety Glass invested in a Forel vertical processing line composed of an Edging Machine Art. EM, a Drilling and Milling Machine Art. DM and a Washing Machine Art. VW.

This downward vertical integration strategy will offer continuity to the production in Spain of EVA for laminated glass.

Glass façade takes center stage in new mixed-use development in Mexico City thanks to SentryGlas® from Trosifol

Live demos, talks with our experts and in-depth analysis of the main trends of the glass market.

NARDOVETRO is able to provide customers with efficient technology for the realization of all types of printing artworks for endless applications.

Between 27 and 30 October 2020, the virtual LiSEC Campus will be welcoming visitors from around the world.