Others also read

Tecglass develops Jetver HA, a laser-focused ink for the home appliances industry.

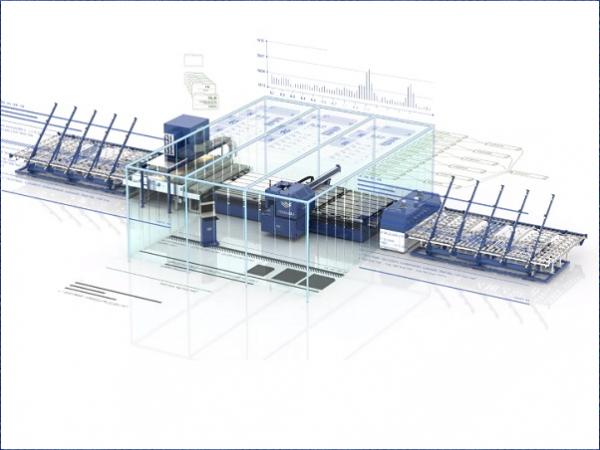

The Rapidstore, as an automated storage system, simplifies manufacturing methods and gives business owners greater capacity.

We demonstrate the superior reliability and behaviour of AB-AR over other structural interlayers

To celebrate the centennial anniversary of Hornos Industriales Pujol, the company has launched its most technologically advanced oven on the market.

Show Room Automotive Glass Mass Production.

The contribution of Bovone to the advancement of the glass industry towards the 4.0 horizon.

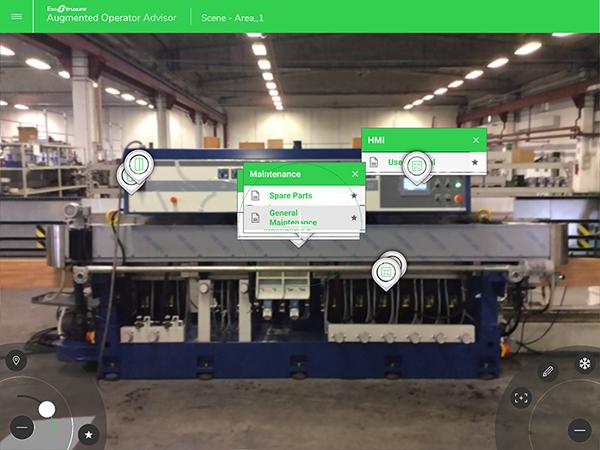

Industry 4.0, digitalization of processes, remote assistance: the levers of Bovone Group to enhance the business of its customers.

Federico Ratti, Innovations Director, sits on the committee, representing the global leader group in machines and industrial components.

The process of affirmation of 4.0 technologies on the current industrial scenario saw a significant acceleration in 2020.

This presentation documents the proper handling methods and processing conditions for the lamination of SentryGlas® SG5000 and SentryGlas® Xtra™ (SGX™) SG6000 ionoplast interlayers.

Pujol has developed a new oven that can carry out high-quality chemical tempering of glass. This oven is designed to work with any type of glass, thickness or shape.

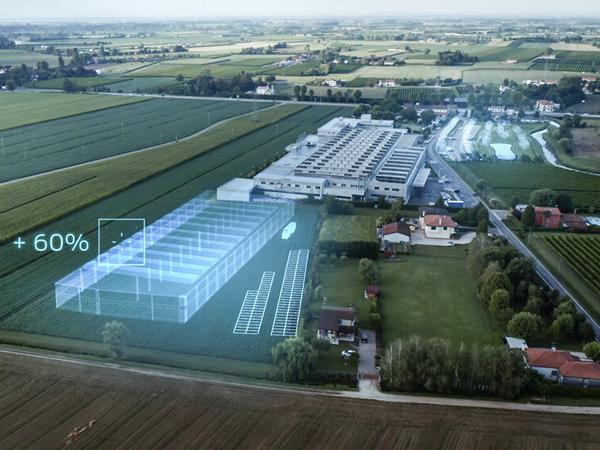

The enlargement of the Forel production plant (Treviso-Italy) is set to begin in 2021.

Gaining digital added value and simplifying workflows are the focus of the HEGLA Shop-Floor app, which is available in tablet and smartphone versions.

Without a digitizing solution, customer supplied templates can often be a difficult task, as the Swiss company FRANZ GYSI AG can confirm.

Glaston is launching its new brand to communicate the full strength of the new Glaston.

Work is changing for many different reasons and not just because of the pandemic. How can mobile applications help your workers do more in less time? How can they help you increase your yield or revenue?

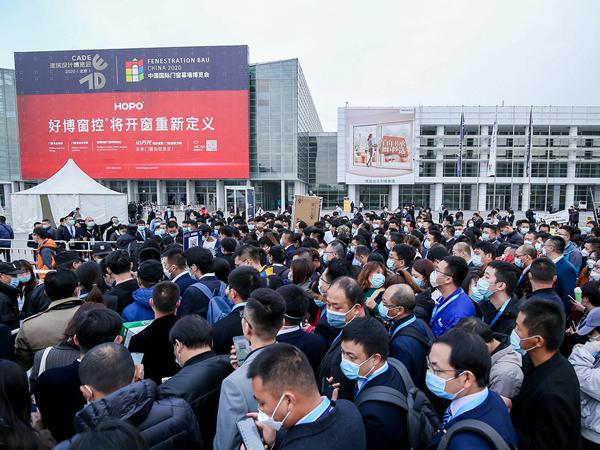

BAU China, the leading trade fair in the Asia-Pacific region for “Building Systems Solutions, High-End Technologies and Materials” was held from October 29 to November 1, 2020.

This downward vertical integration strategy will offer continuity to the production in Spain of EVA for laminated glass.

Live demos, talks with our experts and in-depth analysis of the main trends of the glass market.

Smaller fabricators are consistently overlooked when companies design, market, and sell ERP solutions. A+W Software is changing that for glass fabricators with the launch of our newest product called A+W iCut.

NARDOVETRO is able to provide customers with efficient technology for the realization of all types of printing artworks for endless applications.

Between 27 and 30 October 2020, the virtual LiSEC Campus will be welcoming visitors from around the world.

SCM and CMS, the two benchmark brands in the Scm Group's machinery sector, key players in the 57th edition of Smau, the annual Innovation trade fair held at the Fieramilanocity on 20 and 21 October.