Others also read

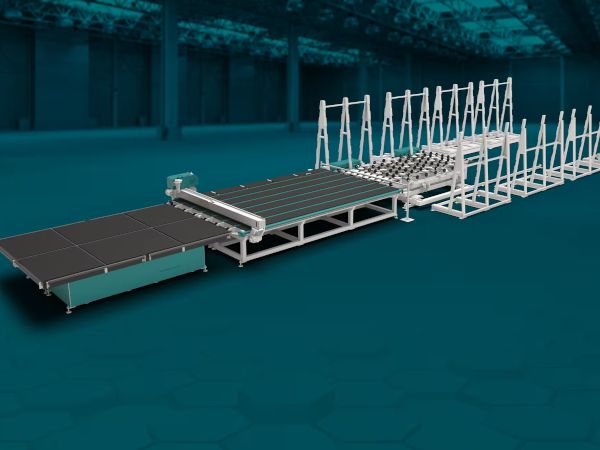

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass.

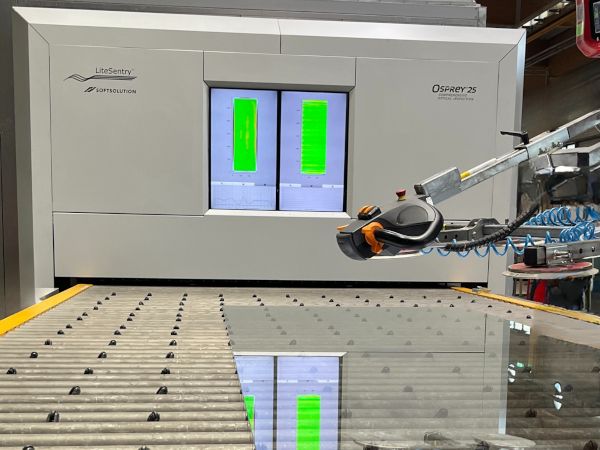

LiteSentry - Softsolution - Strainoptics will present their latest innovations in glass quality inspection at the 2026 Building Envelope Contractors (BEC) Conference.

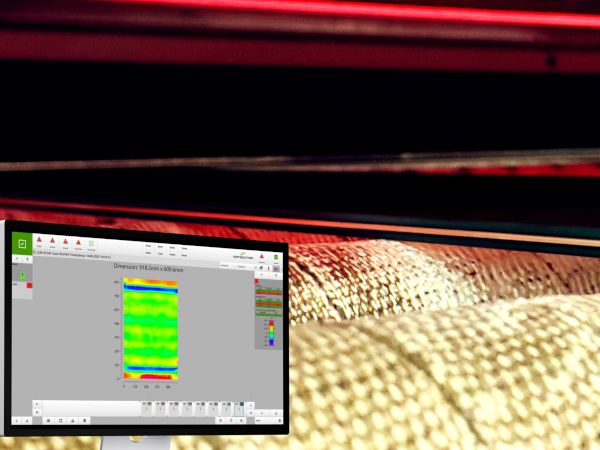

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

New Group CEO brings 25 years of industrial automation leadership to global glassquality companies

TSS is not just technical support – it is a forward-looking partner for realising high performance production solutions.

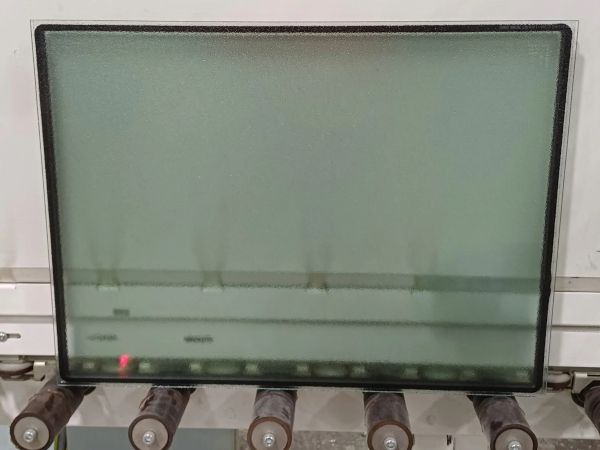

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

LiSEC was named "Austria's Best Managed Company 2025" and took second place in the large companies category in Lower Austria at the prestigious Austria's Leading Companies Award.

On 6 and 7 November, LiSEC welcomed more than 60 customers from Central and Eastern Europe and the Commonwealth of Independent States (CIS) region to Seitenstetten.

LiteSentry – Softsolution will participate in Eurasia Glass Fair 2025, held from November 15–18 at the TÜYAP Fair and Congress Center in Istanbul.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

The strengths and expertise of the MADE products to date will be bundled under the LiTROS brand, developed further and opened up to new target markets.

Automation and precision are redefining flat glass processing. In this expert article, Mika Eronen of Global Glass Specialists explains how dual-metric scanning is transforming quality control and boosting yield across the industry.

Visit Booth #9048 to meet the experts from LiteSentry, Softsolution, and Strainoptics and experience live demonstrations of cutting-edge inspection systems.

When perfection matters, even the slightest bow counts. The Bow Sensor keeps your production line running smoothly with real-time precision and total control.

With its new plant in Port Talbot, Press Glass UK is consolidating three locations and boosting efficiency and growth thanks to LiSEC automation.

Viprotron has unveiled its latest innovation — the Bow Sensor, a cutting-edge solution designed to detect and control glass deformations, or “bows,” early in the production process.

At GlassBuild America 2025, VIPROTRON will demonstrate how its latest inspection technologies are transforming industrial glass production — optimizing measurement, control, and quality across the entire production line.

Considering these six factors aids with installing the LiSEC machine considerably.

We are proud to release the Environmental Product Declaration (EPD) for EVERLAM™ Clearview (0.76), written in accordance with the ISO 14025:2006 and EN15804 standard for building and construction.

The quality and durability of insulating glass units (IGUs) rely on precise manufacturing processes, especially when it comes to gas fill levels and leakage rates.

LiSEC has been named ‘Austria's Best Managed Company 2025’. This competition was organised by Deloitte Austria, Raiffeisen Landesbank Niederösterreich-Wien and the business magazine trend.